High-efficiency short-stroke linear reciprocating oscillation motor

A technology of linear reciprocating and oscillating motors, applied to electrical components, electromechanical devices, etc., can solve problems such as low system efficiency, achieve broad application prospects, low temperature rise, and improve efficiency and life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

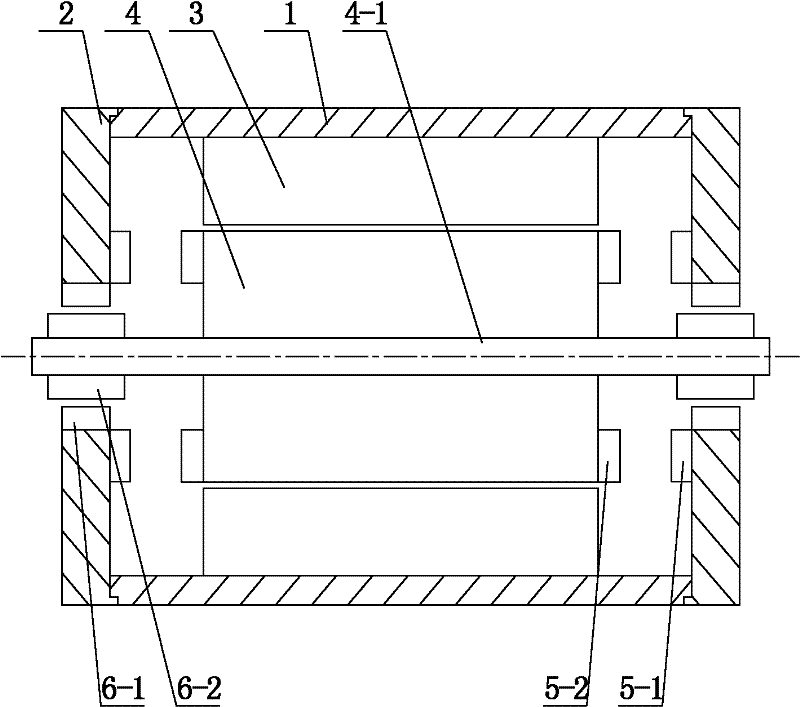

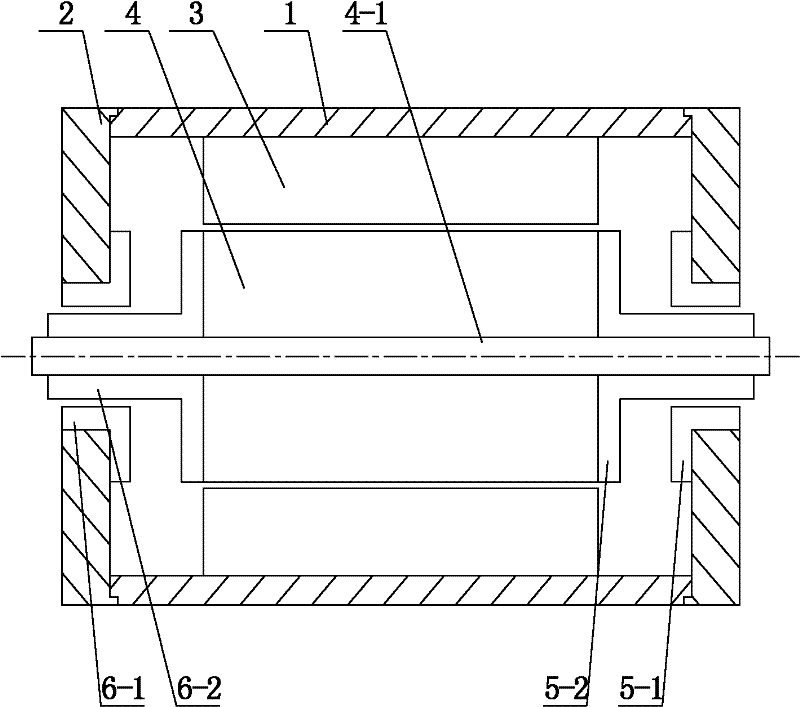

[0032] Specific implementation mode one: the following combination figure 1 and figure 2 Describe this embodiment, the high-efficiency short-stroke linear reciprocating oscillating motor described in this embodiment includes a cylindrical motor housing 1, two end covers 2, a motor stator 3 and a motor mover 4, and the cylindrical motor The two ends of the machine housing 1 are respectively fixedly connected with an end cover 2, and the center of the end cover 2 is provided with a central through hole, and the outer wall surface of the motor stator 3 is centered and fixed on the inner wall surface of the cylindrical motor housing 1. The rotor 4 is located in the inner cavity of the motor stator 3, and is arranged coaxially with the motor stator 3 and the cylindrical motor housing 1. through the center via hole,

[0033] It also includes two magnetic accumulators and two linear magnetic bearings,

[0034] The magnetic accumulator is composed of an accumulator stator 5-1 and...

specific Embodiment approach 2

[0043] Specific implementation mode two: the following combination figure 2 Describe this embodiment. This embodiment is a further description of Embodiment 1. The accumulator stator 5-1 and the bearing stator 6-1 have an integrated structure, and the accumulator mover 5-2 and the bearing mover 6 -2 One-piece structure. Other components and connections are the same as those in Embodiment 1.

specific Embodiment approach 3

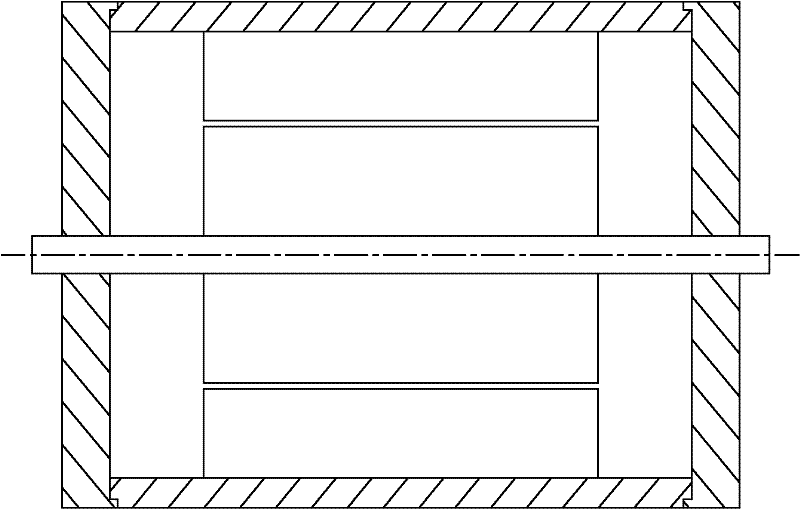

[0044] Specific Embodiment 3: This embodiment is a further description of Embodiment 1 or 2. The bearing stator 6-1 and bearing mover 6-2 of the linear magnetic bearing adopt radial magnetization, and the bearing stator 6-1 and The bearing movers 6-2 are all assembled by a plurality of permanent magnets along the circumferential direction. Other compositions and connections are the same as those in the first or second embodiment.

[0045] In this embodiment, the bearing stator 6-1 and the bearing mover 6-2 are radially magnetized in segments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com