Connecting method of variable cross-section phononic crystal elastic material

A technology of phononic crystals and elastic materials, which is applied in the connection field of phononic crystal elastic materials with variable cross-section, can solve the problems of low initial frequency, insufficient bonding strength, and practical application limitations of phononic crystals, etc., to achieve enhanced bonding strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

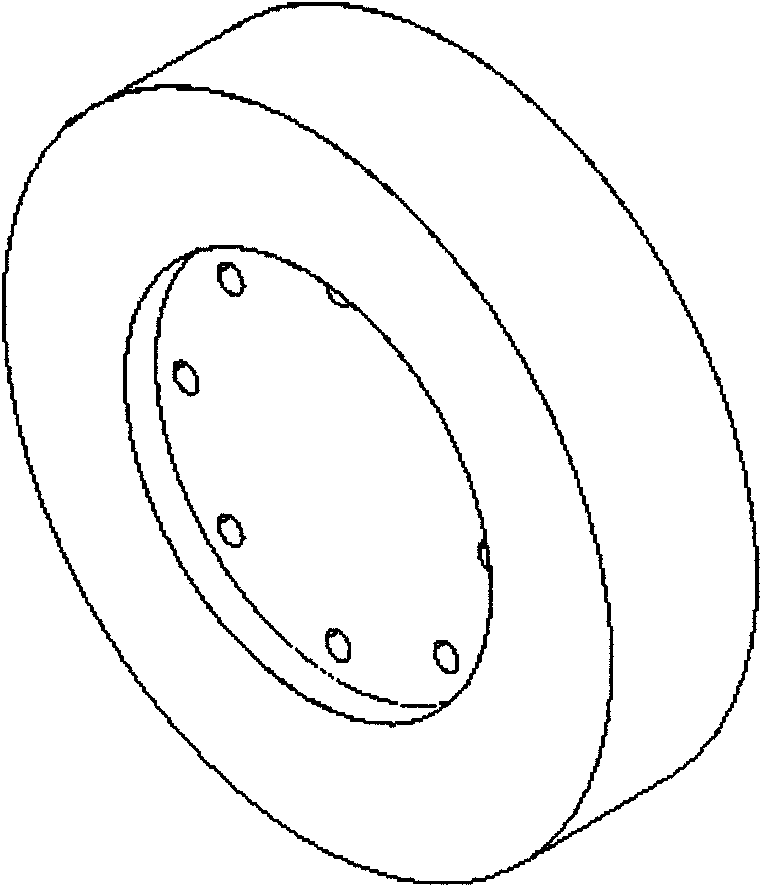

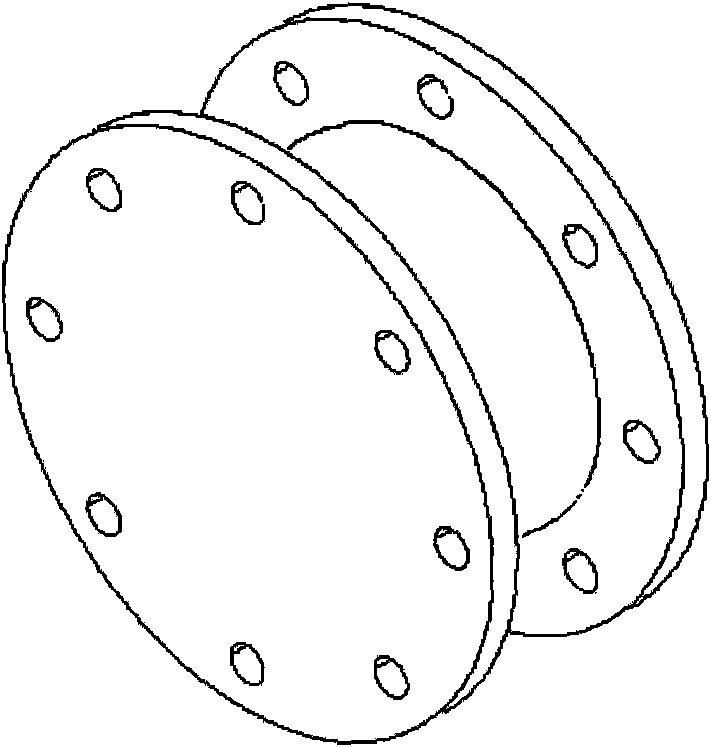

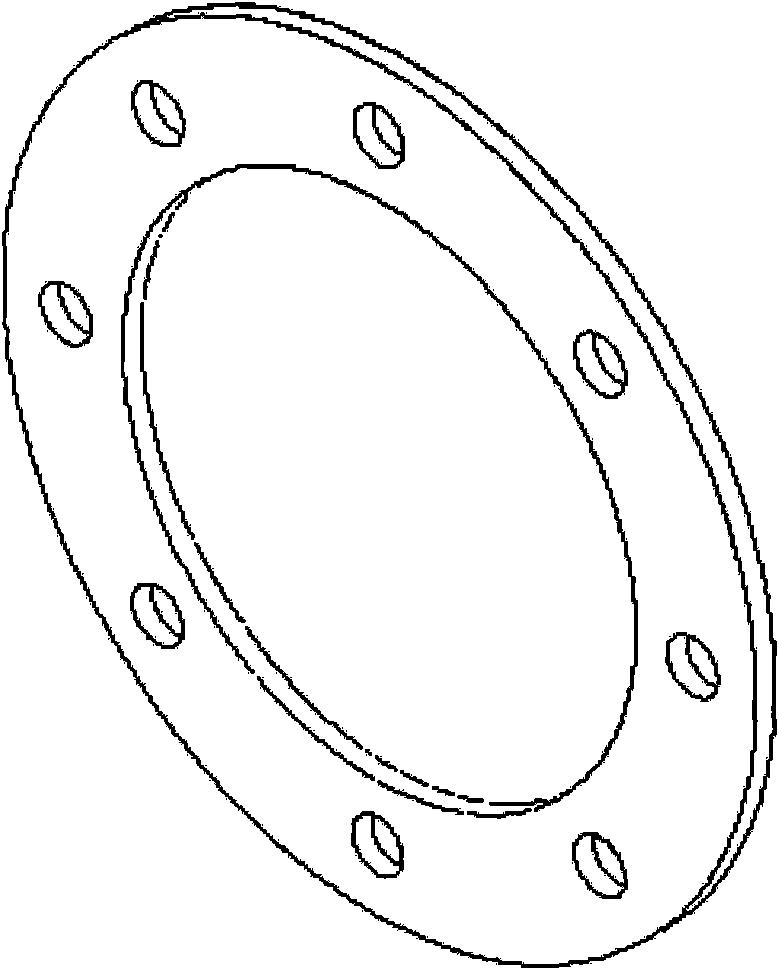

[0019] The variable cross-section phononic crystal elastic material is composed of a copper block and a rubber column. It is characterized in that the copper block and the rubber column are first bonded with glue, then copper pressing sheets are added, and then fixed with bolts. The thickness of the copper pressing sheet is 0.5mm-1mm, the outer diameter is 0.2mm smaller than the groove of the copper block, and the inner diameter is 0.2mm larger than the rubber column.

[0020] The assembly process is:

[0021] (1) Apply glue to the flange of the rubber column and the groove of the copper block first.

[0022] (2) Put the rubber column flange into the groove of the copper block, the threaded holes of the two must match, and then bond.

[0023] (3) Put the copper pressing piece into the rubber column, and then fix the three with bolts.

[0024] (4) Assemble each interface in sequence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com