Concrete strength evaluation method

A concrete strength and concrete technology, which is applied in the field of evaluating concrete strength, can solve problems such as limited use, poor operability, and complicated operation, and achieve the effects of improved feasibility, simple operation, and improved universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

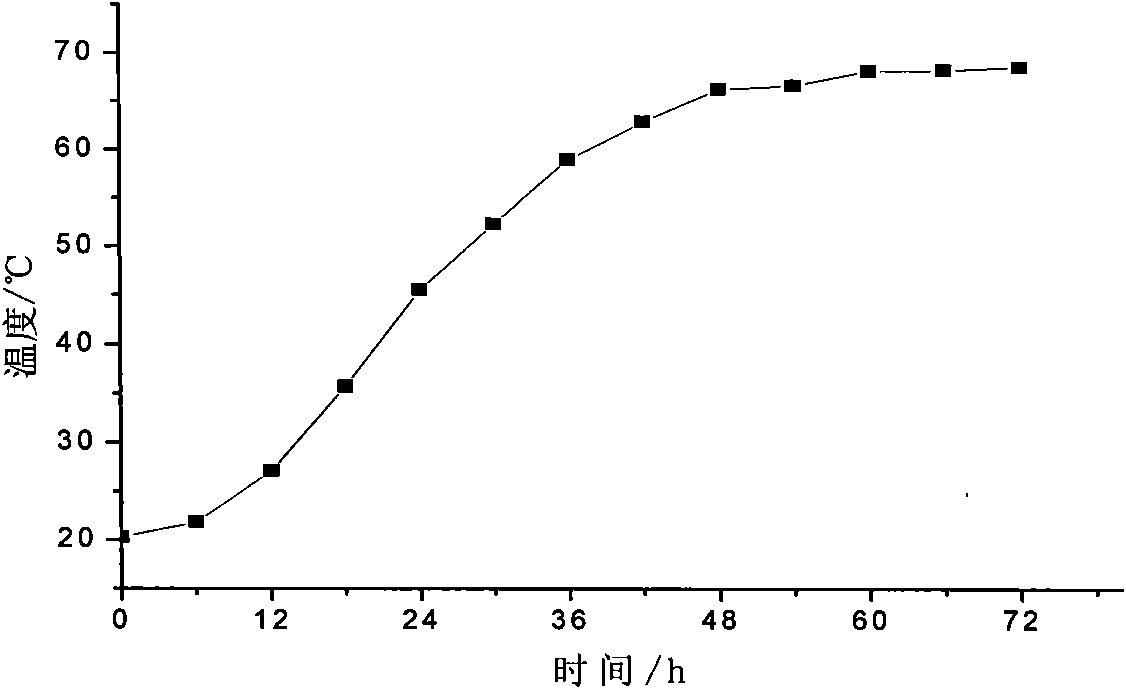

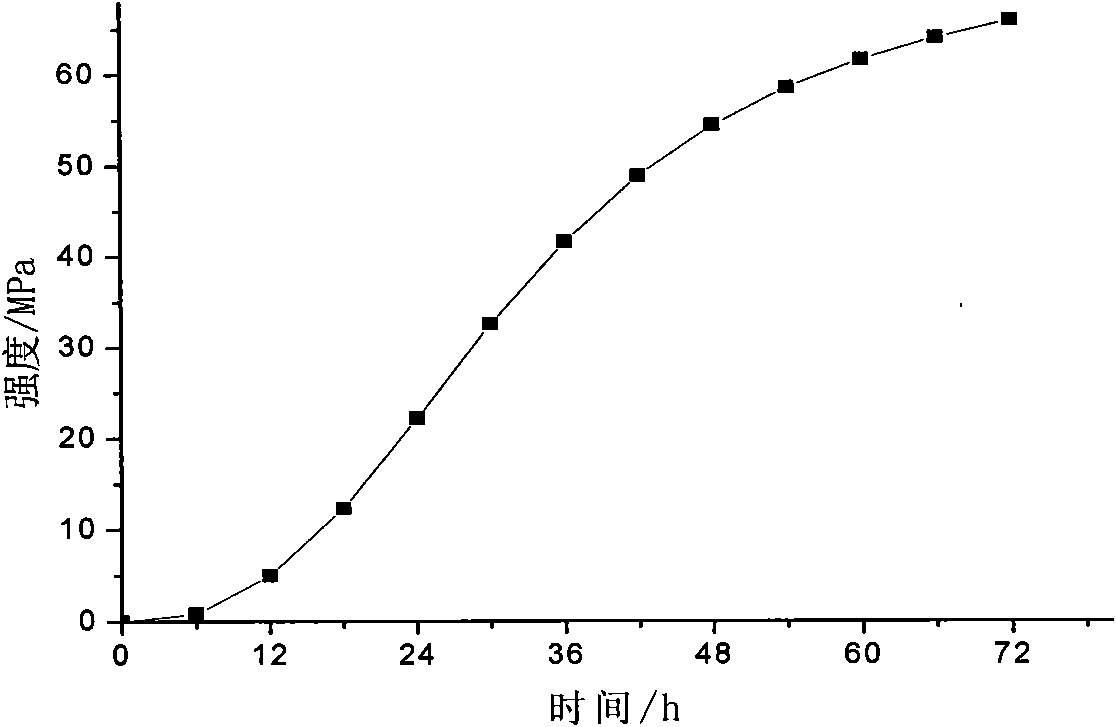

Embodiment 1

[0045] The mass concrete of the base plate of a construction project is marked as C50, and the concrete mix ratio is shown in Table 1. The thickness of the bottom plate is 6m, the bottom surface and the top surface are circular, and the diameter is 12.5m. For construction in spring, the ambient temperature is 20°C, and the mold entry temperature is 15°C. The surface is covered with two layers of film and 2cm straw bags. Conduct temperature monitoring at a certain part of the central axis of the concrete floor to evaluate the strength of the concrete.

[0046] Table 1 Concrete mix ratio of bottom slab

[0047]

[0048] Note: The cement is ordinary Portland cement (PO) 42.5, the particle size of coarse aggregate is 5-25, and the admixture is RP325.

[0049] Figure 4 It is a flowchart of the steps of the method for evaluating the strength of concrete according to the present invention. Please refer to Figure 4 , the strength evaluation steps of concrete using this meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com