Method for measuring distortion of tall chimney based on outline

A measurement method and contour line technology, applied in measurement devices, instruments, optical devices, etc., can solve the problems of weak reflection echo, imprecise, lack of texture information, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be described in detail below with reference to the drawings and specific embodiments.

[0075] The following are the specific steps of chimney measurement:

[0076] 1. Field data acquisition, the steps are as follows:

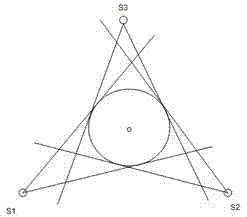

[0077] 1. Layout of control points in the field. The control points are evenly distributed around the chimney, and the average distance from the chimney is moderate. The accuracy of the estimated results is to ensure that the control points are arranged reasonably. Control measurement and determine the spatial coordinates of each control point.

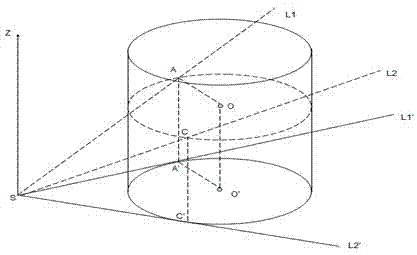

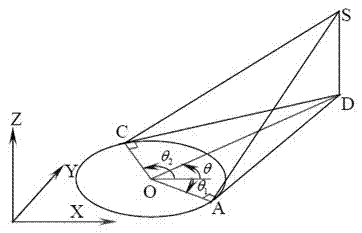

[0078] 2. Set up IS total station and rear-view prism, leveling and centering, and rear-view orientation. After the orientation is completed, the image is taken. First, the total station is aimed at the left outline of the chimney, and the shots are taken from the top of the chimney to the bottom of the chimney. The basic requirement is to take two consecutive photos to ensure that there is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com