Mine water overall treatment utilizing technology

A comprehensive treatment, mine water technology, applied in the direction of drainage, mining equipment, safety devices, etc., can solve the problems of increased wear and tear of drainage equipment, waste of high-quality clean water, and increased sewage treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

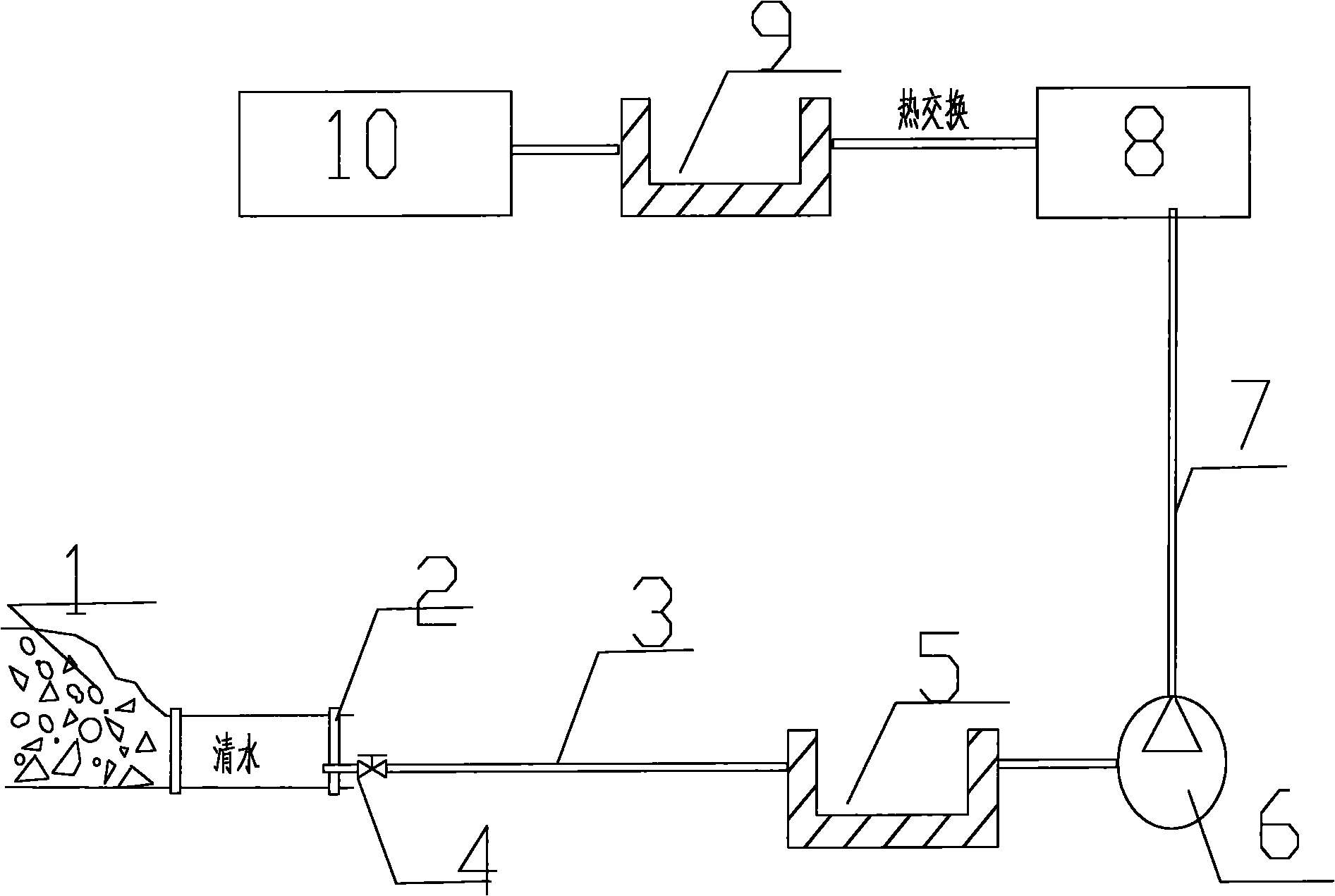

[0015] Technical scheme of the present invention is as follows:

[0016] A method for comprehensive treatment and utilization of mine water, including the utilization of goaf clear water, dredging water and underground sewage treatment, the steps are as follows:

[0017] 1. Utilization of warm water in goaf

[0018] A water-retaining airtight wall is built at the outer end of the roadway in the gob area of the mine working face. Water pipelines and water control gate valves are installed inside the wall. Clean water at 25-28°C in the goaf is led from the water-retaining wall to the underground clean water warehouse through the pipeline. Inside, the clean water at 25-28°C is directly delivered to the pipeline of the ground heat pump unit through the water pump, and the heat obtained by the heat exchange is used intensively.

[0019] 2. Borehole water is used as underground dust-proof water

[0020] Drill holes directly to the Austrian ash layer in the underground, and the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com