Recovery method of common combined mining working face hydraulic support

A fully mechanized mining face and hydraulic support technology, which is applied to mine roof supports, pillars/supports, mining equipment, etc., to achieve the effects of fast recovery, high safety factor, and saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

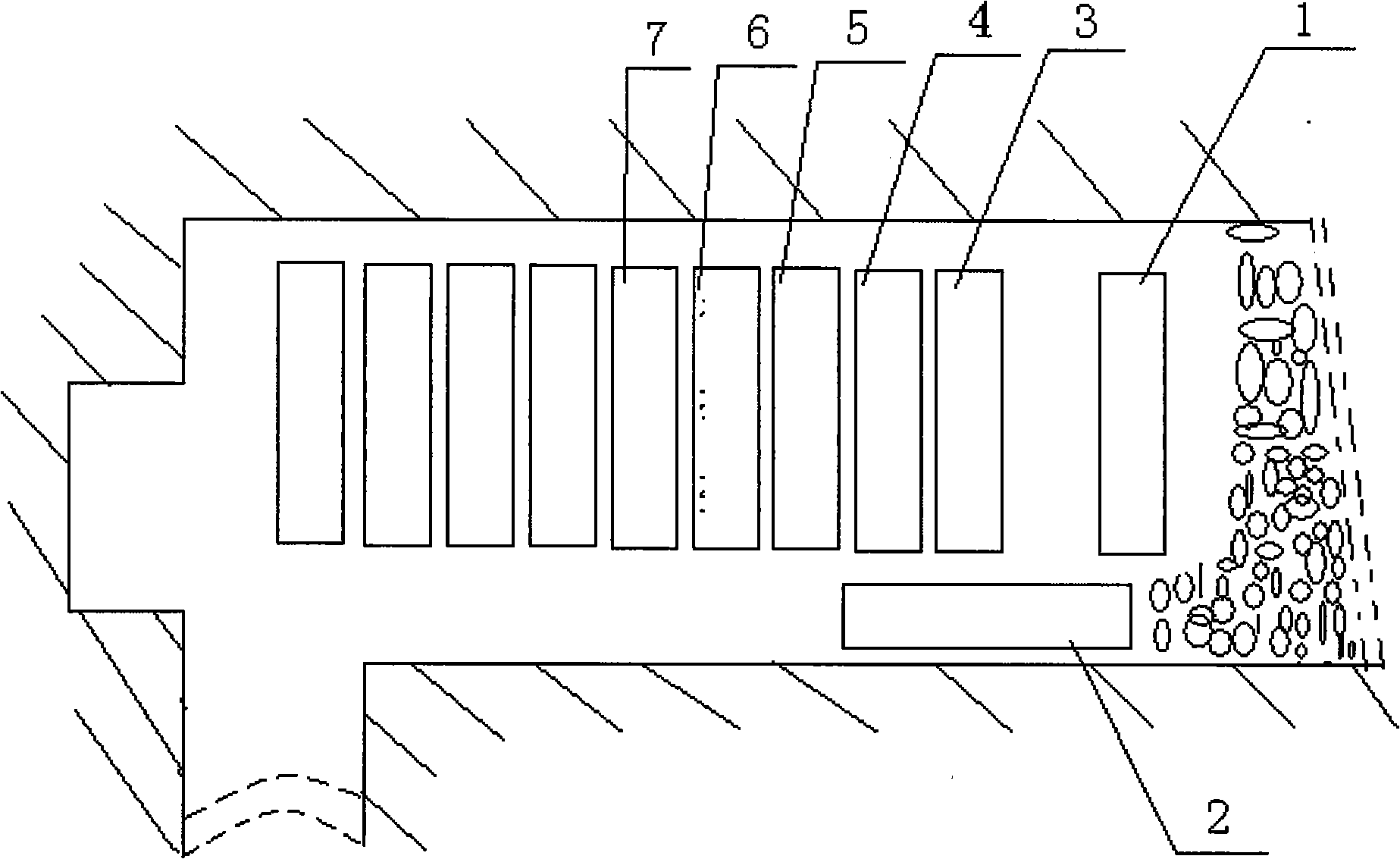

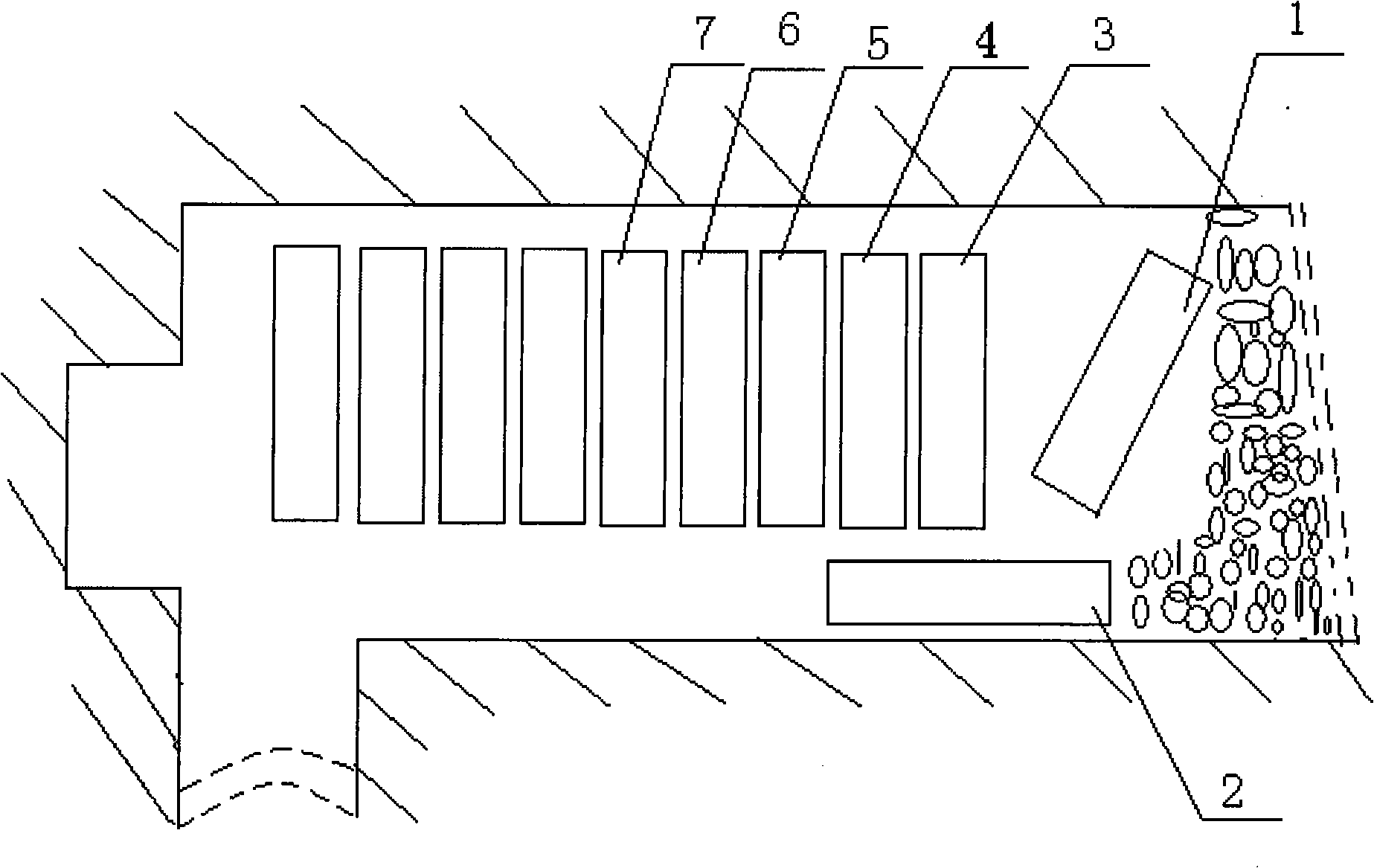

[0009] A method for recovering a hydraulic support in a common fully mechanized mining face, such as figure 1 As shown, if there are 100 supports to be recovered in front of the work, start from the work surface, such as figure 2 As shown, the penultimate hydraulic support 2 is first pulled out and raised on the side of the coal wall as the No. 1 cover frame, and the original roof is supported by "one beam and four columns" at the original position of the penultimate hydraulic support, as shown in image 3 As shown, the penultimate hydraulic support 1 is cable-stayed as the No. 2 shield frame; as Figure 4 As shown, then the penultimate fourth hydraulic support 4 is pulled out and transported away, and at the same time, "one beam and four columns" is used to support the original roof at the original position of the penultimate fourth hydraulic support, as shown in Figure 5 As shown, the penultimate hydraulic support 3 is tilted as the No. 3 shield frame, as Figure 6 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com