Automatic control system for sealant amount of automatic seal line for hollow glass

An automatic control system, glass technology, applied in coatings, devices for coating liquid on the surface, etc., can solve problems such as easy failure and complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

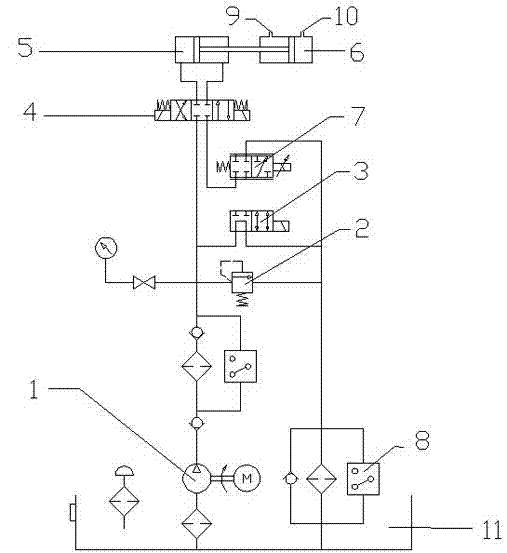

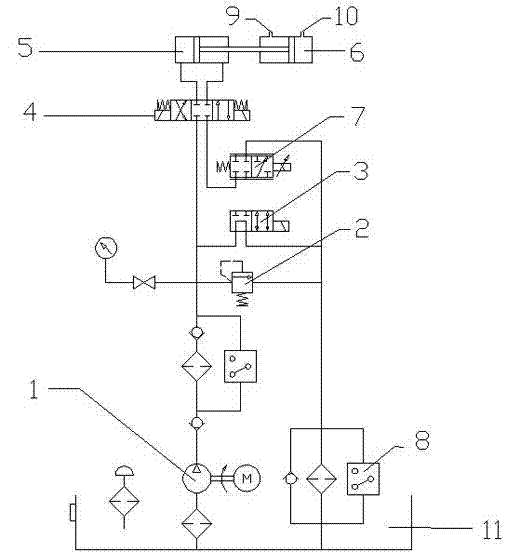

[0010] figure 1 The automatic control system for the amount of glue on the automatic glue sealing line for hollow glass includes a hydraulic system, a glue extrusion cylinder 6 and a hydraulic cylinder 5, and a piston is arranged in the glue extrusion cylinder 6, and the piston defines a rod chamber and a rodless chamber. and having a piston rod extending from the piston. There is a vent hole 9 for communicating with the outside air on the wall of the rod chamber; the rodless chamber is filled with glue, and a row of glue ports 10 are opened on the wall of the chamber to communicate with the rodless chamber and the glue discharge channel.

[0011] The hydraulic cylinder 5 is provided with a piston which defines a rod chamber and a rodless chamber. The piston of the extrusion cylinder 6 and the piston of the hydraulic cylinder 5 are connected by a piston rod.

[0012] The hydraulic system includes an oil pump 1 connected to the motor, an oil tank 11,

[0013] The first elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com