Method for constructing bridge deepwater foundation steel pile casing

A deep-water foundation and construction method technology, which is applied in basic structure engineering, construction, sheet pile walls, etc., can solve the problem of difficult control of the cumulative error of the straightness of the steel casing, the inability of large lifting equipment to enter the site, and the low safety and quality assurance factor. problems, to achieve the effect of strong ability to adapt to changes in hydrological conditions, strong ability to resist construction risks, and economical and reasonable construction investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

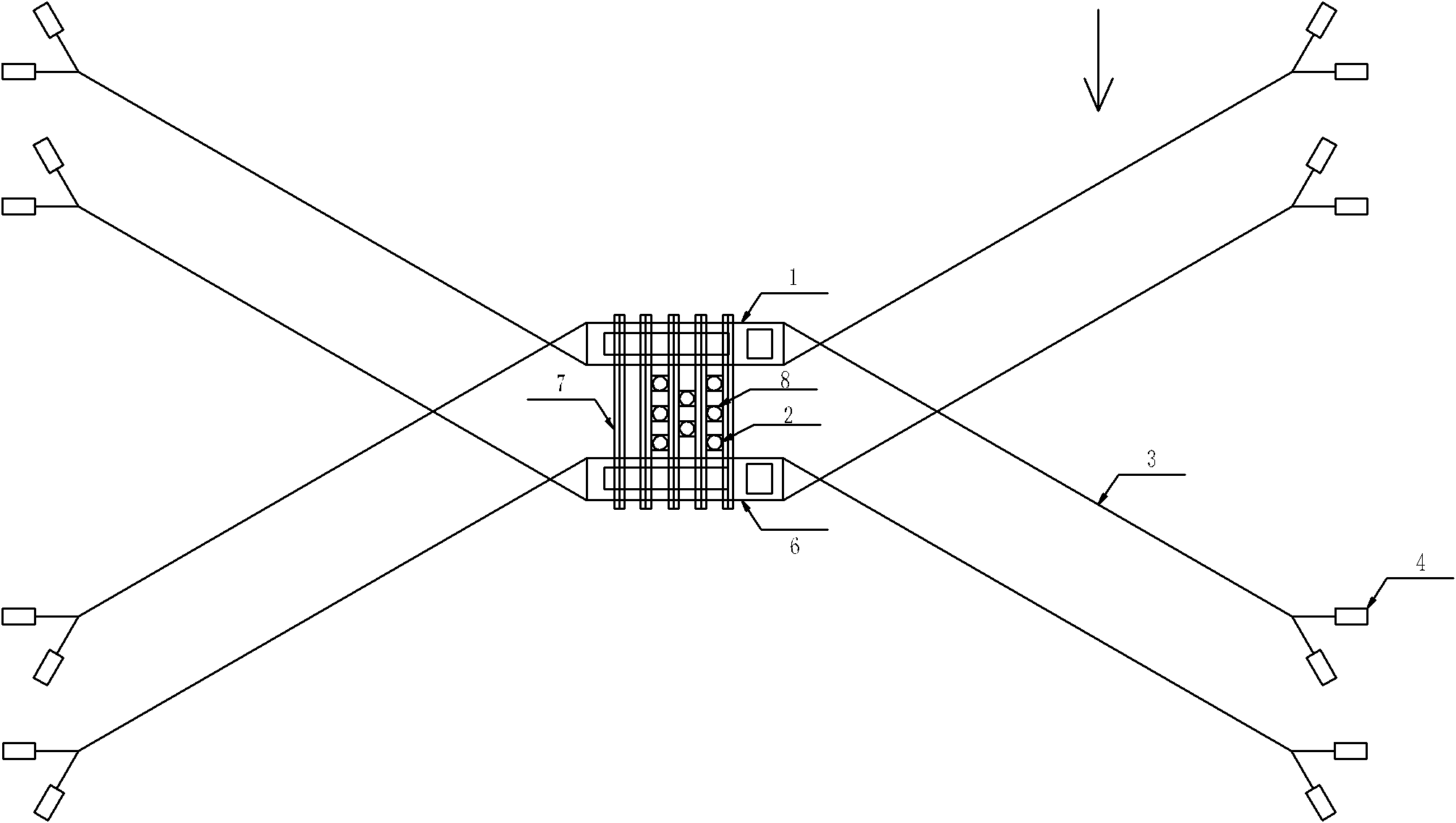

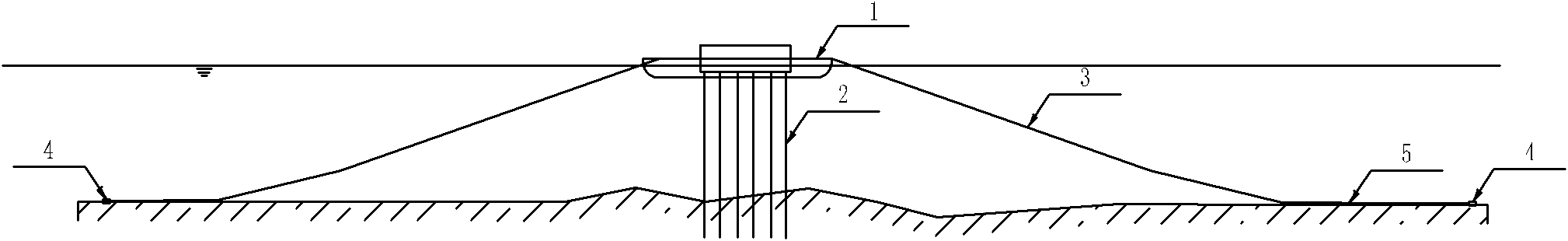

[0032] see Figure 1 to Figure 5 , the specific construction process is as follows: the steel casing is manufactured in vertical sections, and the length of each section is 2m; the steel casing is welded between the sections on the assembly pedestal, and the two ends are sealed after the connection length is 40m, and one end is set The air inlet is set at the other end, and the water inlet is set at the other end; enter the water by sliding down the slideway, and use a tugboat to float and tow to the bridge position; open the air outlet at the top of the steel casing and the water inlet valve at the bottom of the casing or Switch; the bottom mouth of the steel casing slowly sinks into the water, and the top mouth gradually lifts out of the water until the steel casing is in a vertical suspension state; continue to exhaust to gradually reduce the water outlet height of the steel casing until the steel casing can freely pass through the bottom layer of the floating platform Dist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com