Fire extinguishing system of wind generating set

A technology of wind power generators and fire extinguishing systems, applied in the field of fire extinguishing systems, can solve problems affecting precision instruments and equipment, high system cost, and unusable places with people, so as to achieve the effects of improving safety, good fire extinguishing effect, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

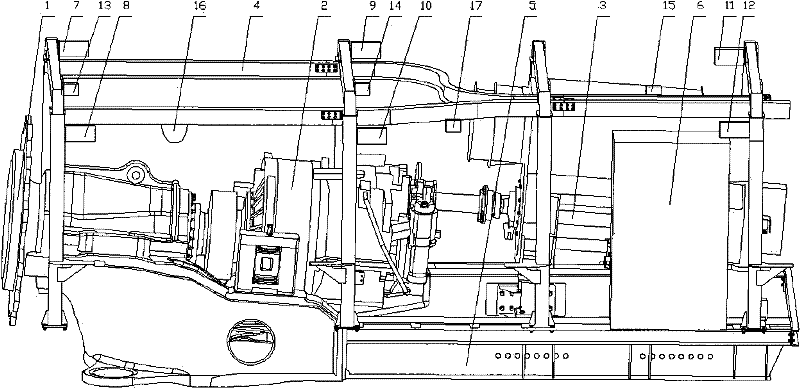

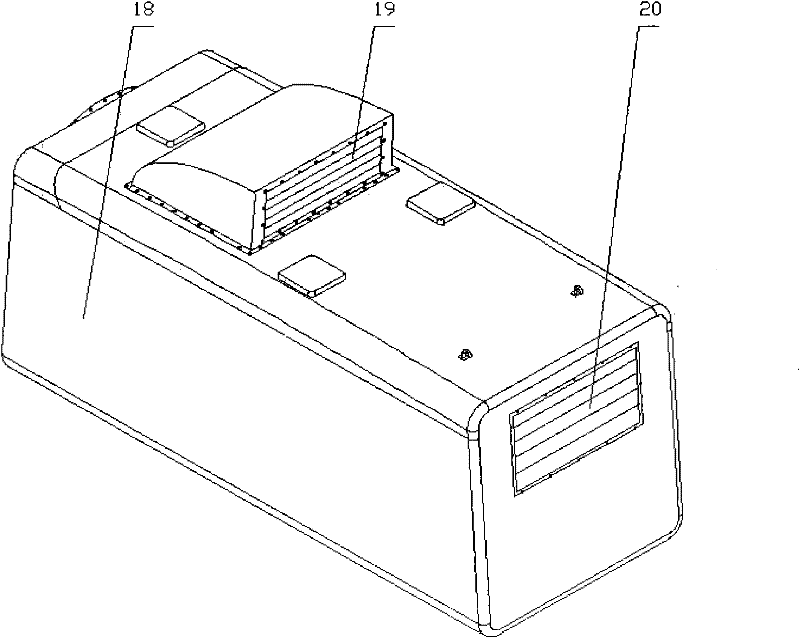

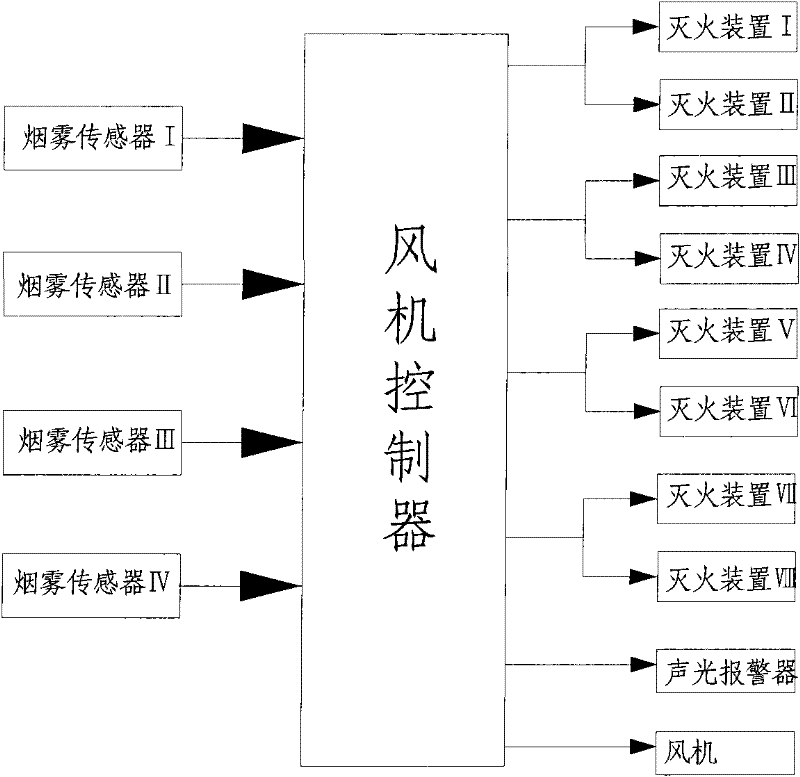

[0020] like figure 1 , 2 , 3, 4, the accompanying drawing provides an example of the present invention, the present invention will be further described below in conjunction with accompanying drawing and example, but protection of the present invention is not limited to the content shown in example. In the present invention, a main shaft 1 , a gear box 2 , a generator 3 , an internal frame 4 , a nacelle underframe 5 and a fan controller 6 are arranged in the nacelle. The nacelle outer cover is a nacelle cover 18 on which electric control shutters are installed, six fire extinguishers and three smoke sensors are all distributed in the wind turbine nacelle, and the sound and light alarm 16 is also installed in the wind turbine nacelle. The signal input end of the fan controller 6 is connected with the signal output ends of the smoke sensor and the pressure sensor 17, and the control signal output end of the fan controller 6 is connected with the control signal input ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com