Test method and test device for torsional composite fretting friction wear

A test method and test device technology, applied in the direction of testing wear resistance, can solve problems such as affecting safe production and shortening the service life of parts and components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

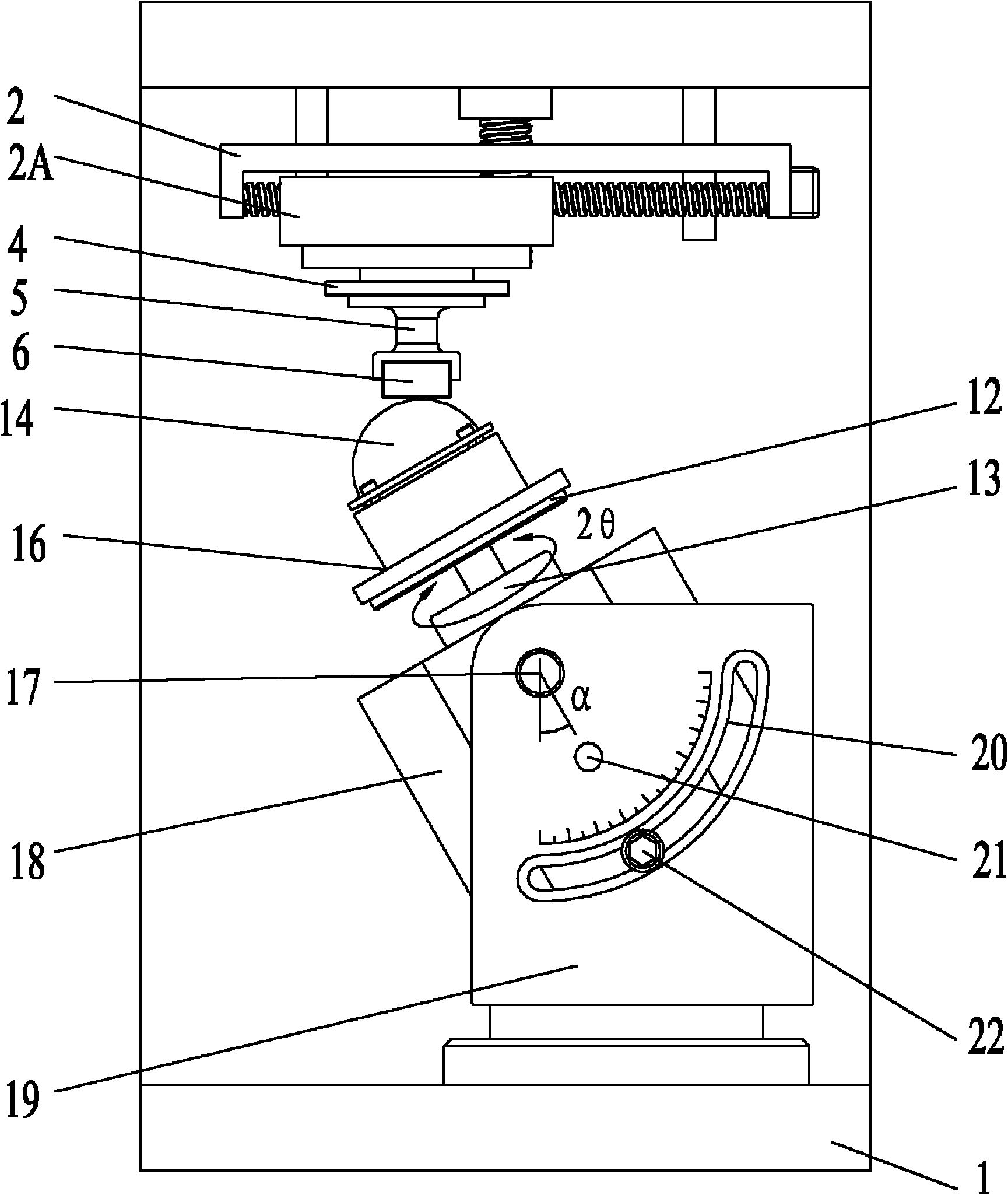

[0043] A specific embodiment of the present invention is: a test method for torsional compound fretting friction and wear, the practice is:

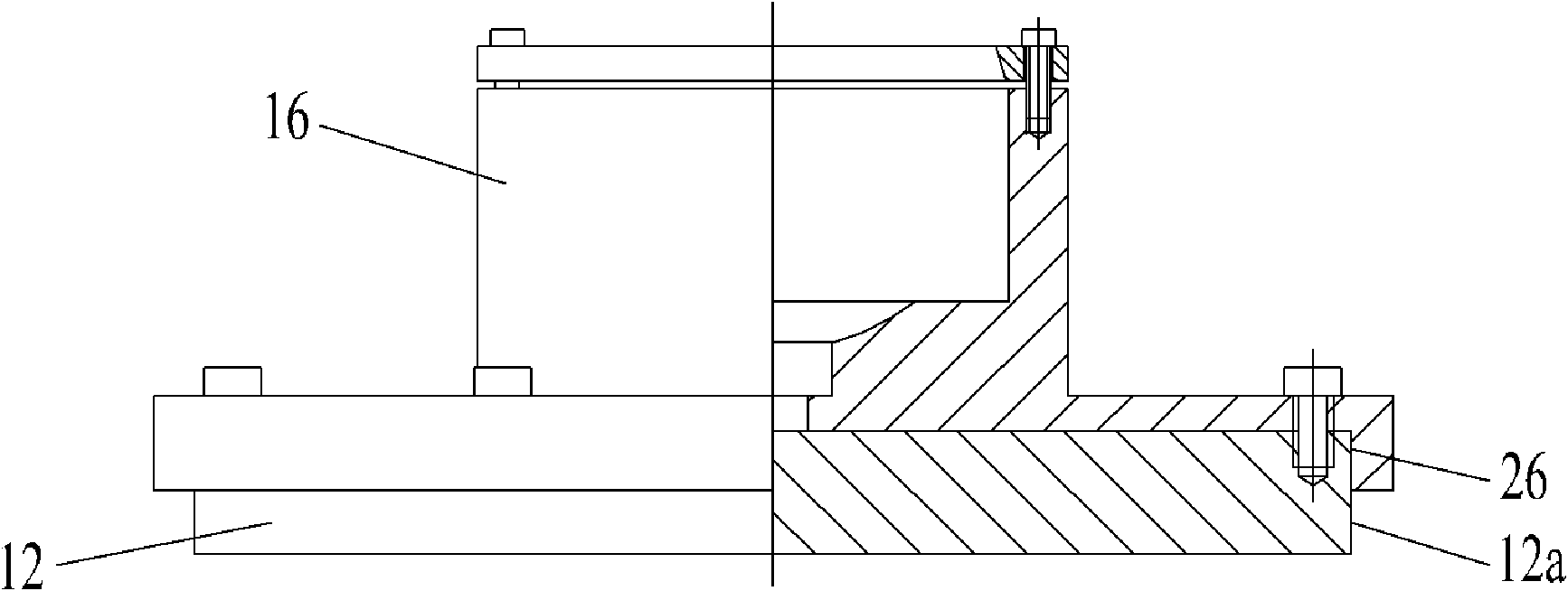

[0044] a. Clamp the upper test piece 6 of the plane on the upper fixture 5, and the upper fixture 5 is fixed on the six-dimensional force / moment sensor 4, and the spherical lower test piece 14 is clamped by the lower fixture 16, and the lower fixture 16 is fixed on the inclined On the mounting plate 12 on the output shaft of the high-precision ultra-low-speed rotary motor 13, the center of the spherical lower test piece 14 is located on the axis of the rotary motor 13 output shaft;

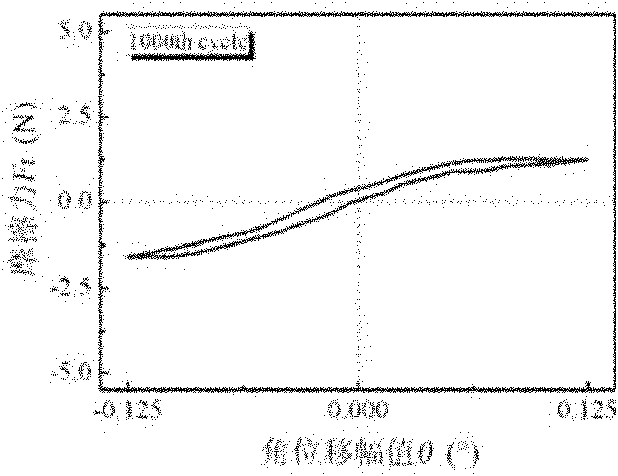

[0045] b. Control the up and down, left and right movement of the upper fixture 5 and the upper test piece 6 held by the data acquisition control system, so that the upper and lower test pieces 6, 14 are in contact and the upper and lower test pieces 6, 14 are kept set At the same time, the data acquisition and control system controls the rotary motor 13 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com