Fiber strain sensitive structure and manufacturing method thereof

A technology of optical fiber strain and sensitive structure, applied in the direction of using optical devices, optical waveguide coupling, measurement devices, etc., can solve the problems of limited capillary structure, limited elastic range, easy fatigue, etc., to reduce manufacturing costs, flexibility Large range, performance-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

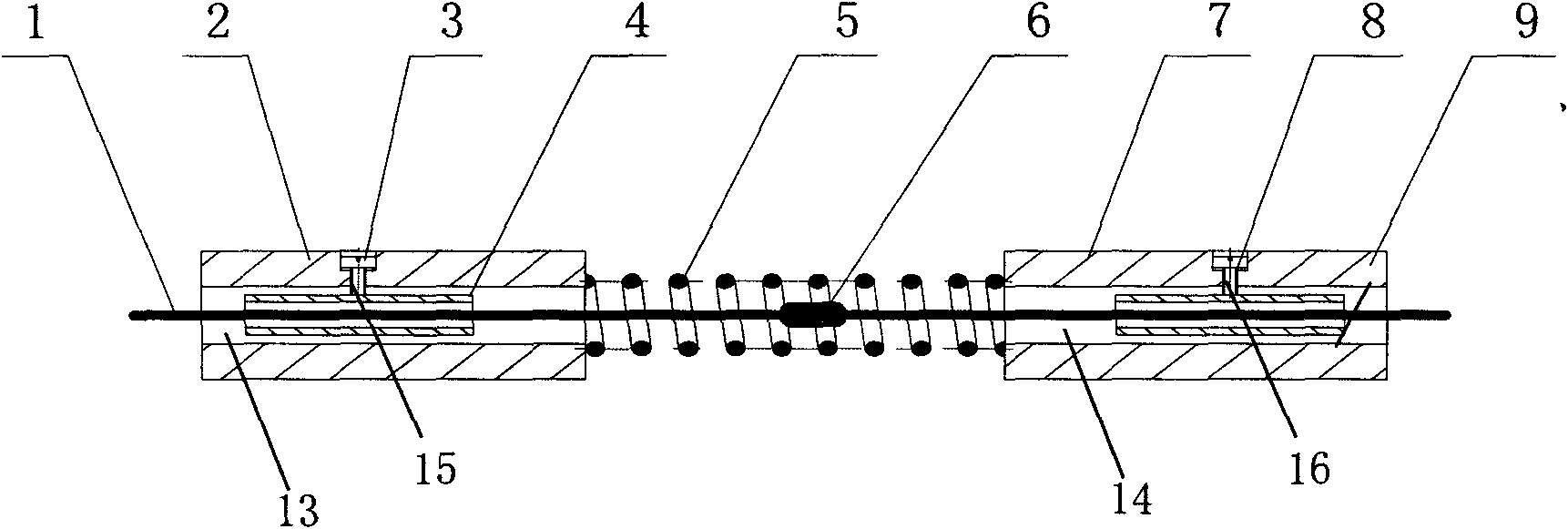

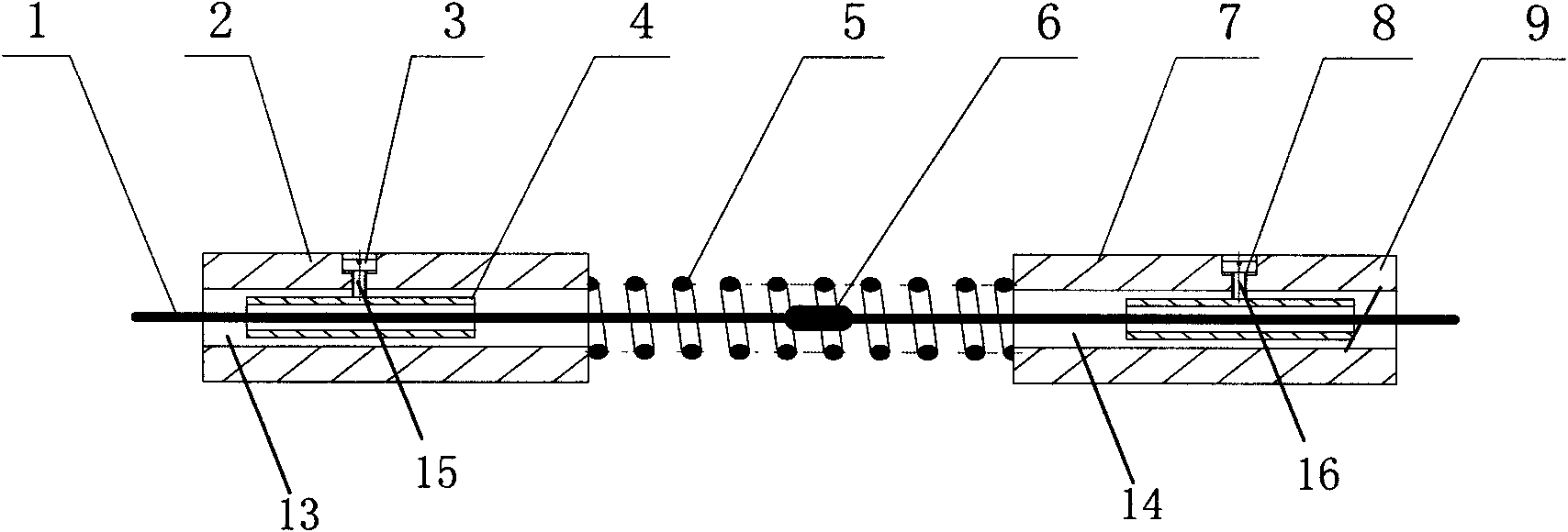

[0025] Such as figure 1 As shown, the optical fiber strain sensitive structure of the present invention includes: an optical fiber 1 provided with an optical fiber strain sensitive unit 6, a left optical fiber holder 2, a spring 5 and a right optical fiber holder 7 arranged in sequence and fixedly connected to each other, and a left optical fiber holder 2 A first through hole 13 communicating with the left and right is provided, and a second through hole 14 communicating with the left and right is provided in the right optical fiber fixing base 7 . The optical fiber 1 is glued together with the left fiber fixing capillary 4 and the right fiber fixing capillary 9 which are sleeved on the fiber 1 and located on the left and right sides of the fiber strain sensitive unit 6 respectively to form an optical fiber assembly. The fiber assembly passes through the first through hole 13, the spring 5 and the second through hole 14, so that the left fiber fixing capillary 4 is placed and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com