High total pressure large-flow wheel disk side beveling type back-ward impeller fan

A backward-curved impeller, high-flow technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of centrifugal fan radial exhaust that does not meet the requirements, low operating efficiency, and large fan volume. The effect of increasing the effective work area, reducing the loss and increasing the degree of expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further described in conjunction with the above technical solutions and accompanying drawings.

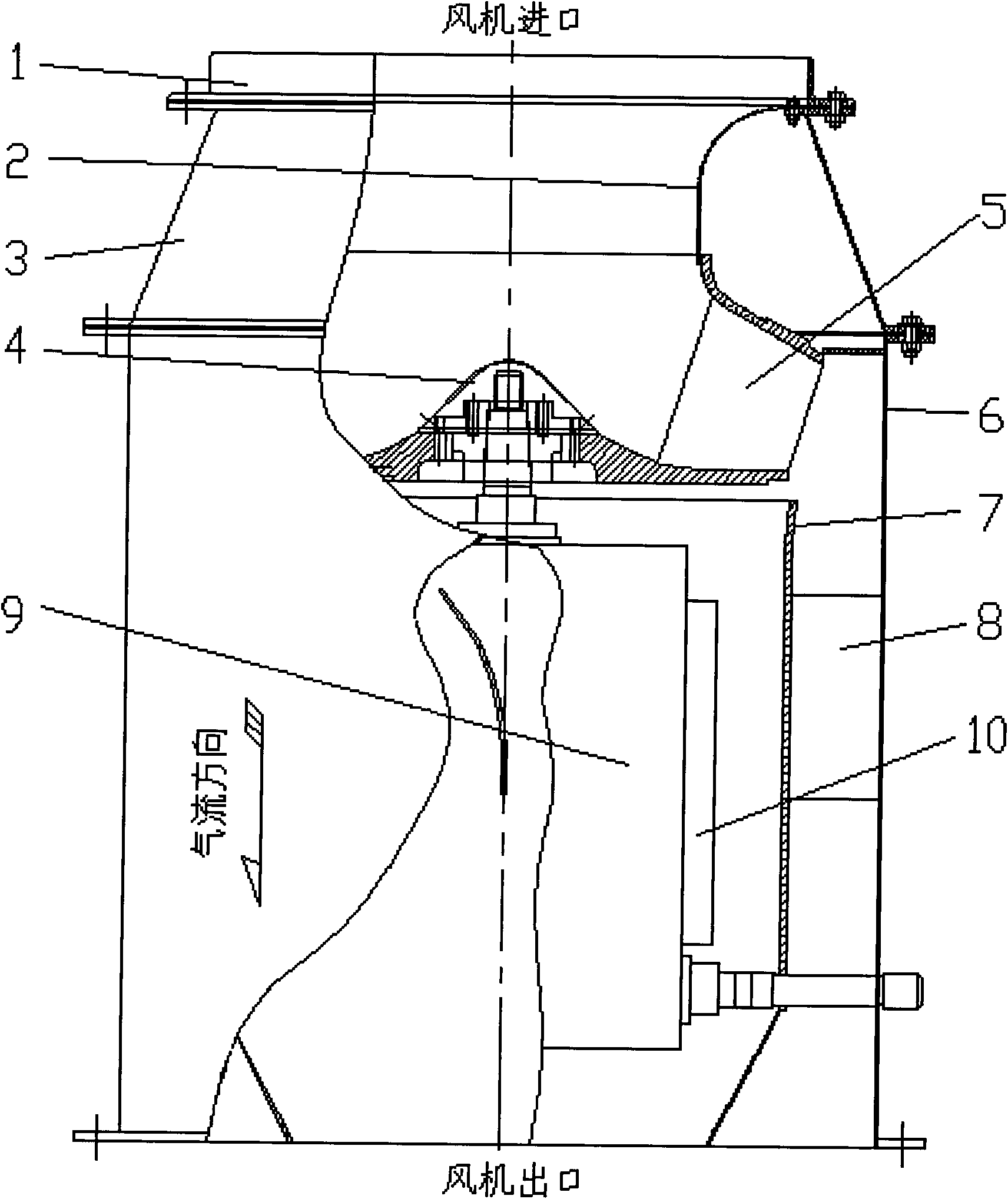

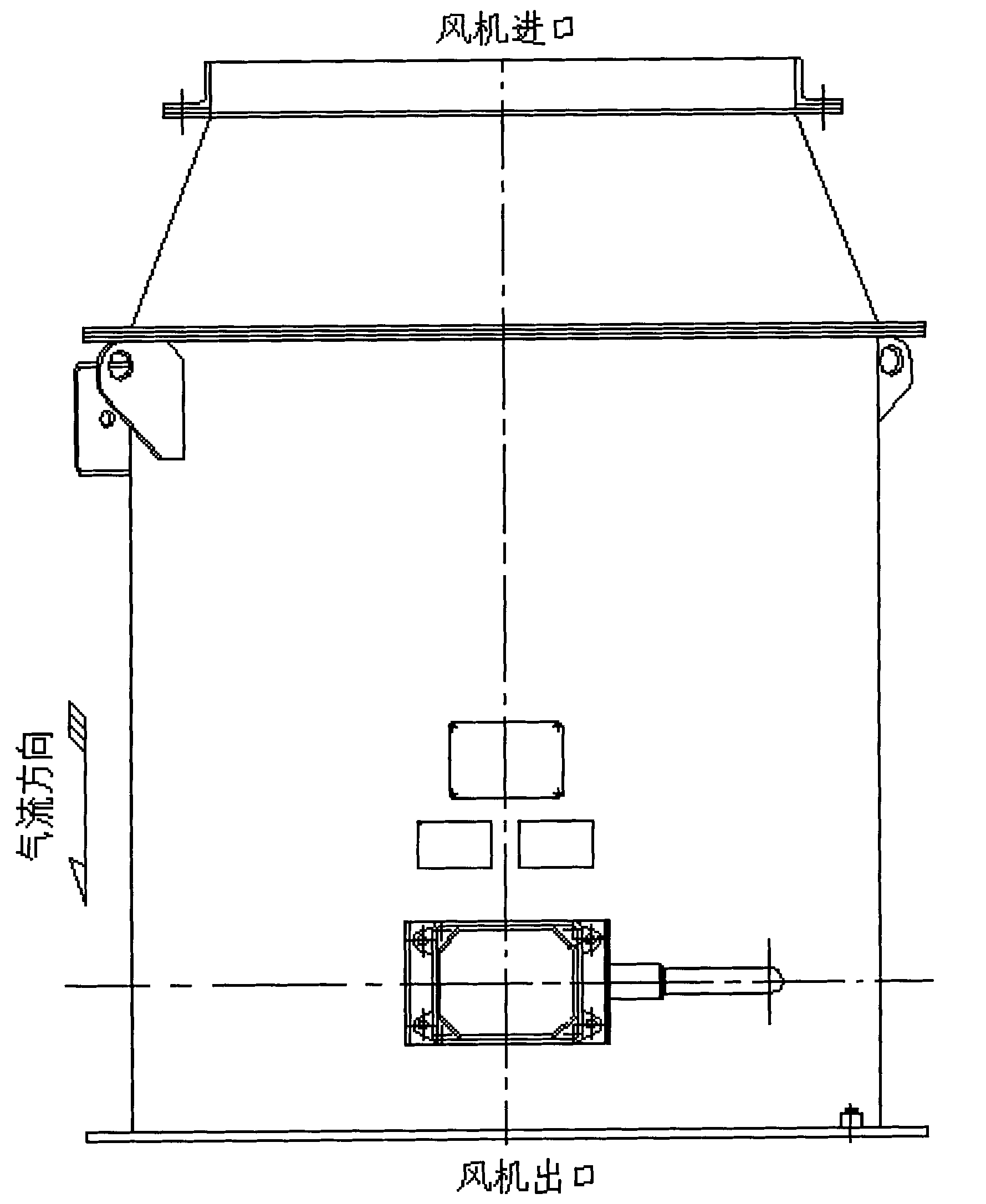

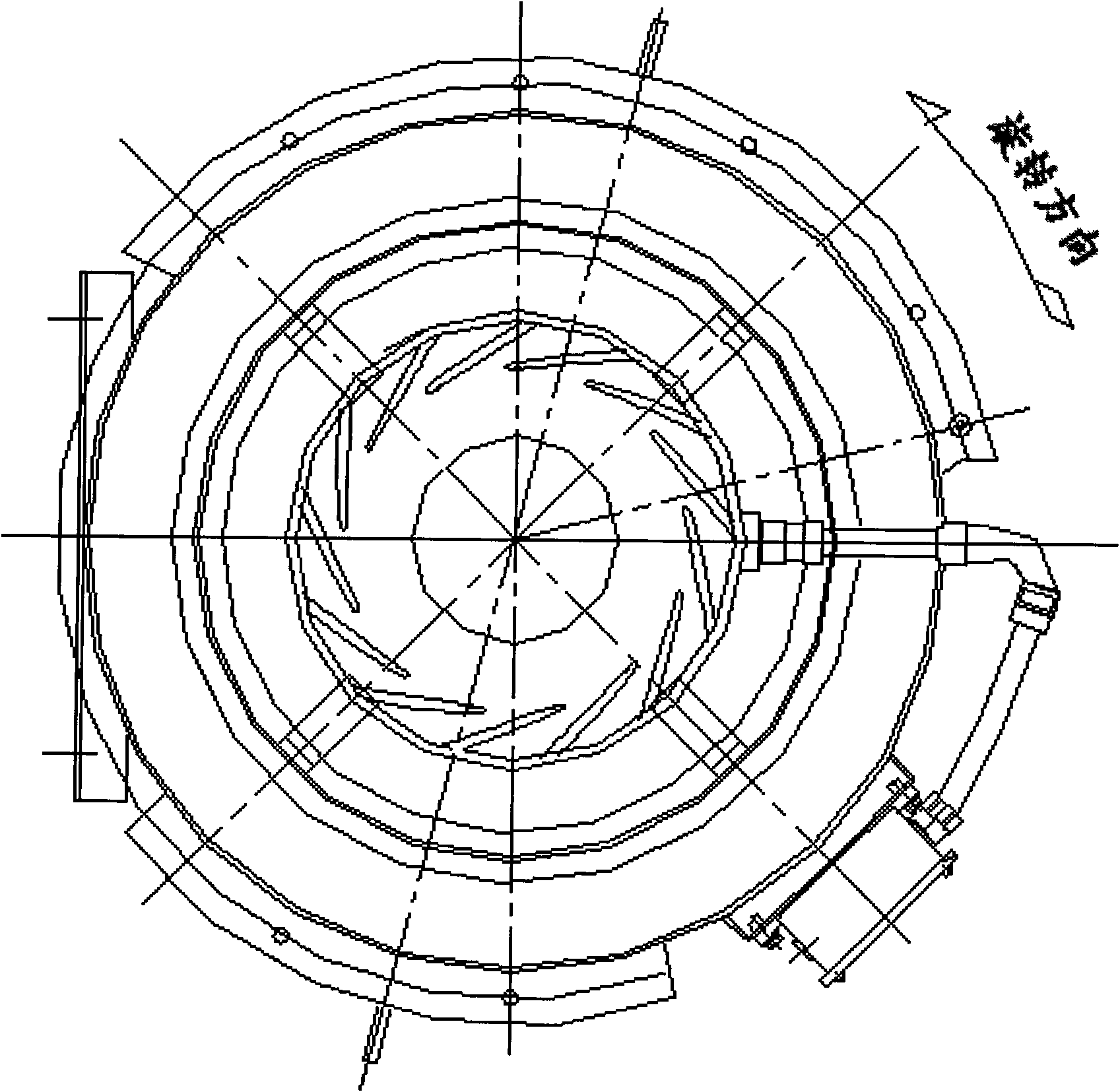

[0026] As shown in the figure, a high full-pressure and large-flow disc-side beveled backward-curved impeller fan according to the present invention consists of an angle steel flange 1, an air guide cover 2, an air inlet tube 3, an inlet guide cover 4, The impeller 5, the outer cylinder of the air outlet cylinder 6, the inner cylinder of the air outlet cylinder 7, the guide vane 8, the motor 9 and the bracket 10 etc. are composed. The impeller 5 is placed in the air inlet tube 3 and connected with the motor 9, and the motor 9 is fixed on the inner cylinder 7 of the air outlet tube through a bracket 10. The end of the air inlet tube is provided with an air inlet, and the air outlet tube includes two parts: the outer cylinder of the air outlet tube 6 and the inner tube of the air outlet tube 7. The cylinder inner cylinder 6 and the motor 9 constitute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com