Power raising method for turboprop aero-engine

An aero engine and engine technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of engine improvement that have not been seen in relevant research and reports, and achieve improved plateau starting performance, increased flow capacity, and take-off equivalent power Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

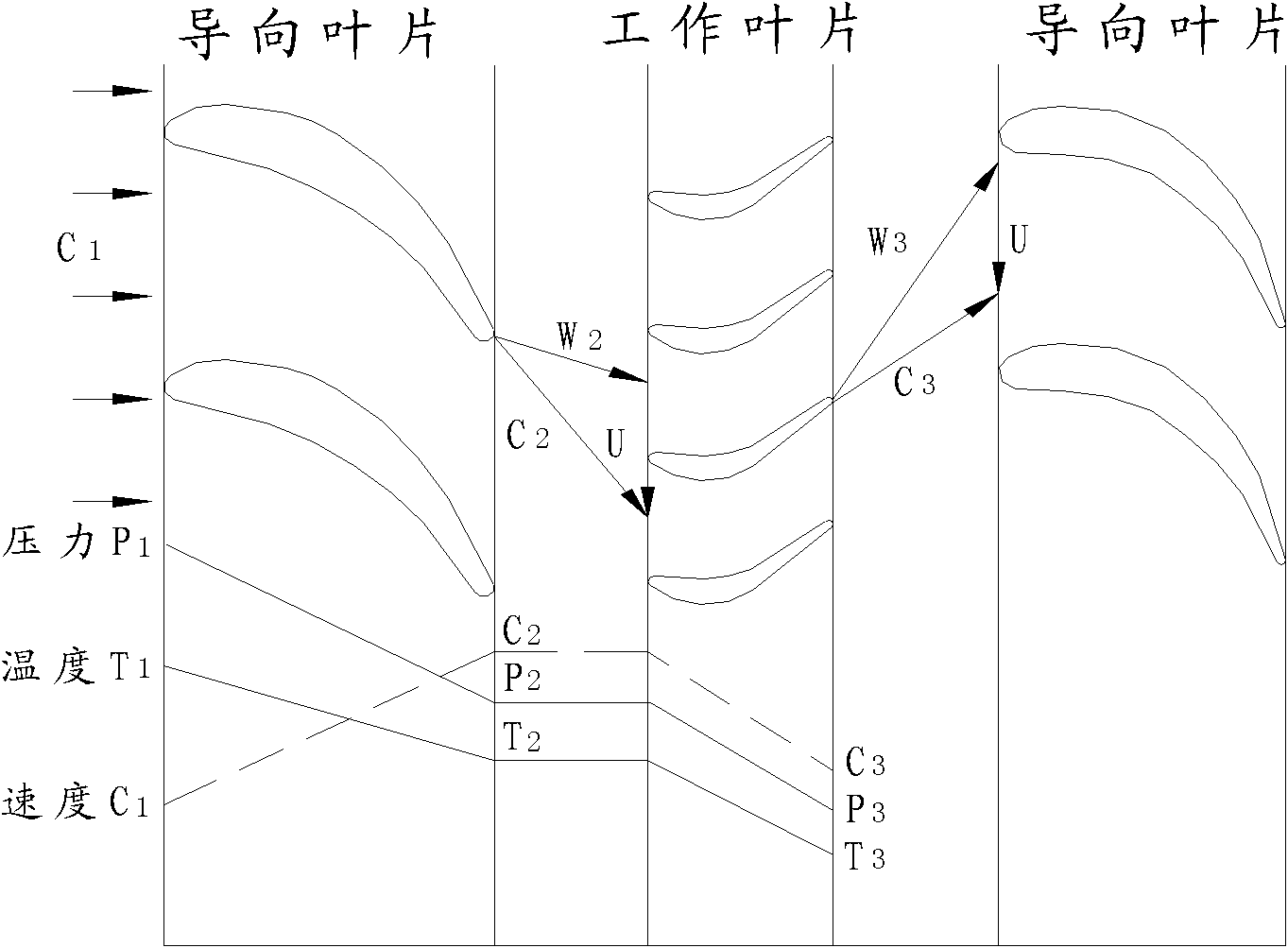

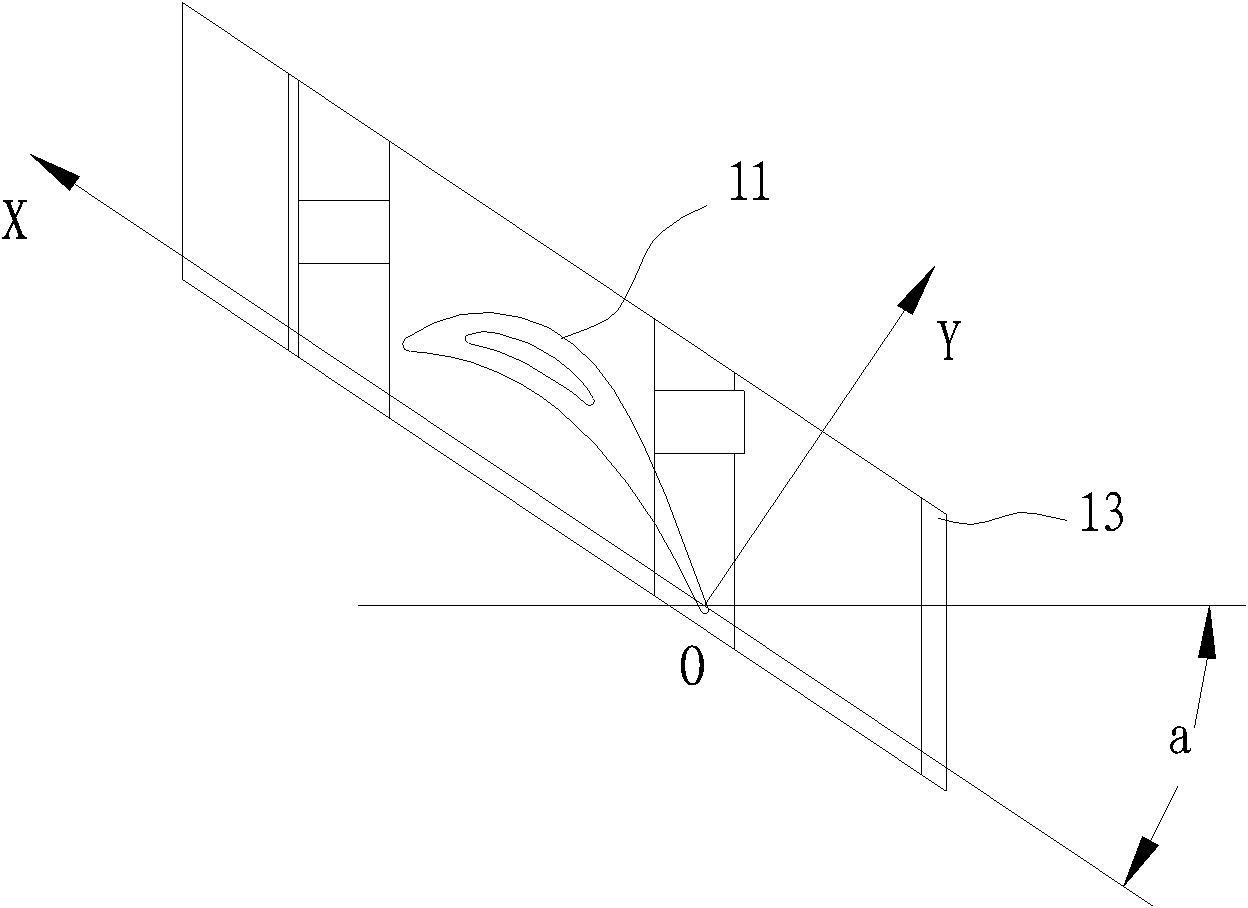

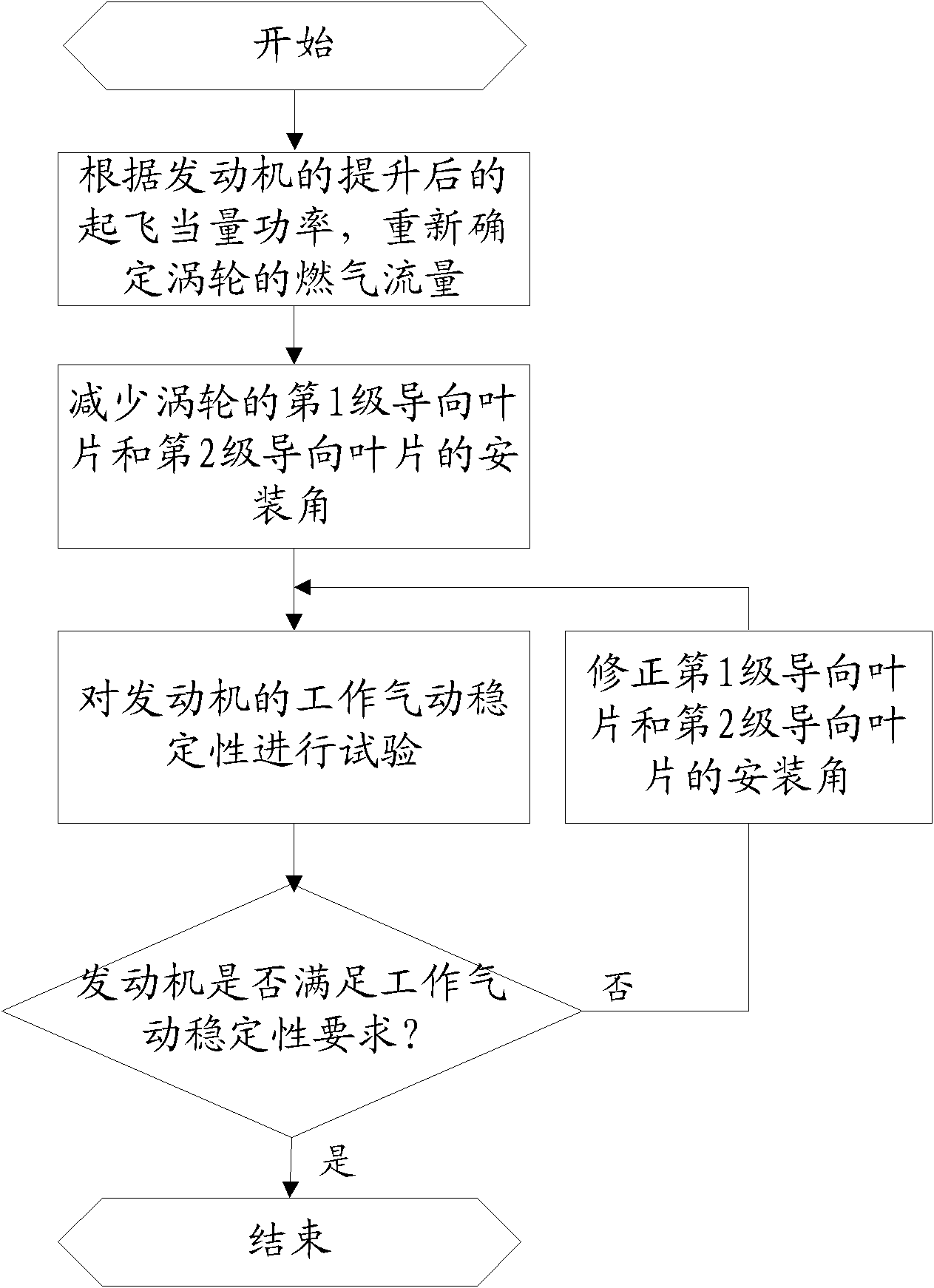

[0031] According to a certain type of turboprop aeroengine improved according to the power boosting method of the present invention, under the premise of keeping the engine installation interface, operating speed and adjustment law basically unchanged, the installation angle of the first stage guide vane of the turbine is reduced by 1.5 degrees, The installation angle of the guide vanes of the second stage turbine is reduced by 1 degree, the flow capacity of the turbine is improved, and the aerodynamic stability requirements of the engine are met at the same time.

[0032] Under the requirement that the take-off equivalent power of the engine increases from 3125kW to 3750kW, it is determined that the maximum fuel flow of the turboprop engine increases from 1030kg / h to 1200kg / h, and the gas temperature at the turbine inlet increases from 1065K to 1160K.

[0033] The material of the first-stage guide vane and the second-stage guide vane of the above-mentioned turbine is preferabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com