Scaffold arranged in electroplating bath and provided with hole on side edge

A technology of electroplating tanks and floating racks, which is applied in the electrolysis process and electrolysis components, etc. It can solve the problems of uneven coating thickness and uneven coating, and achieve the effects of improving the uniformity of the coating, reducing waste, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

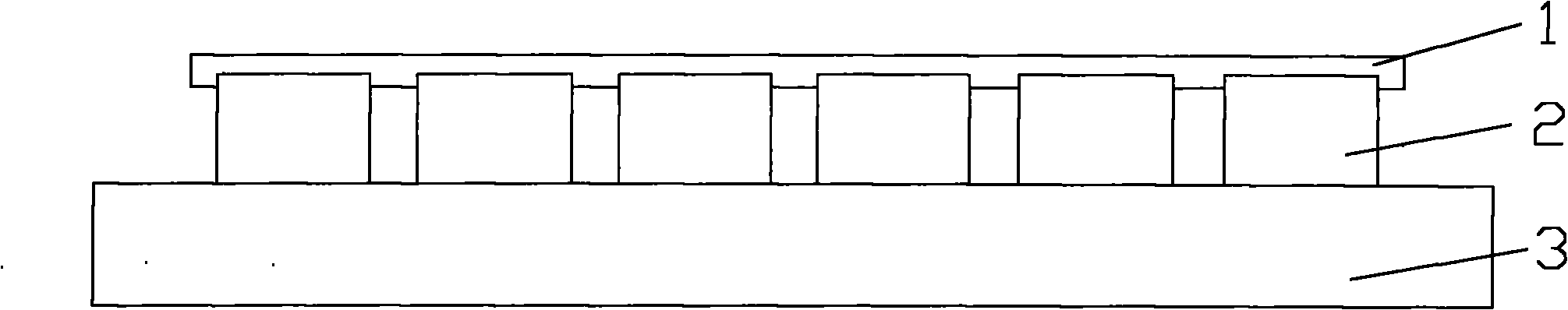

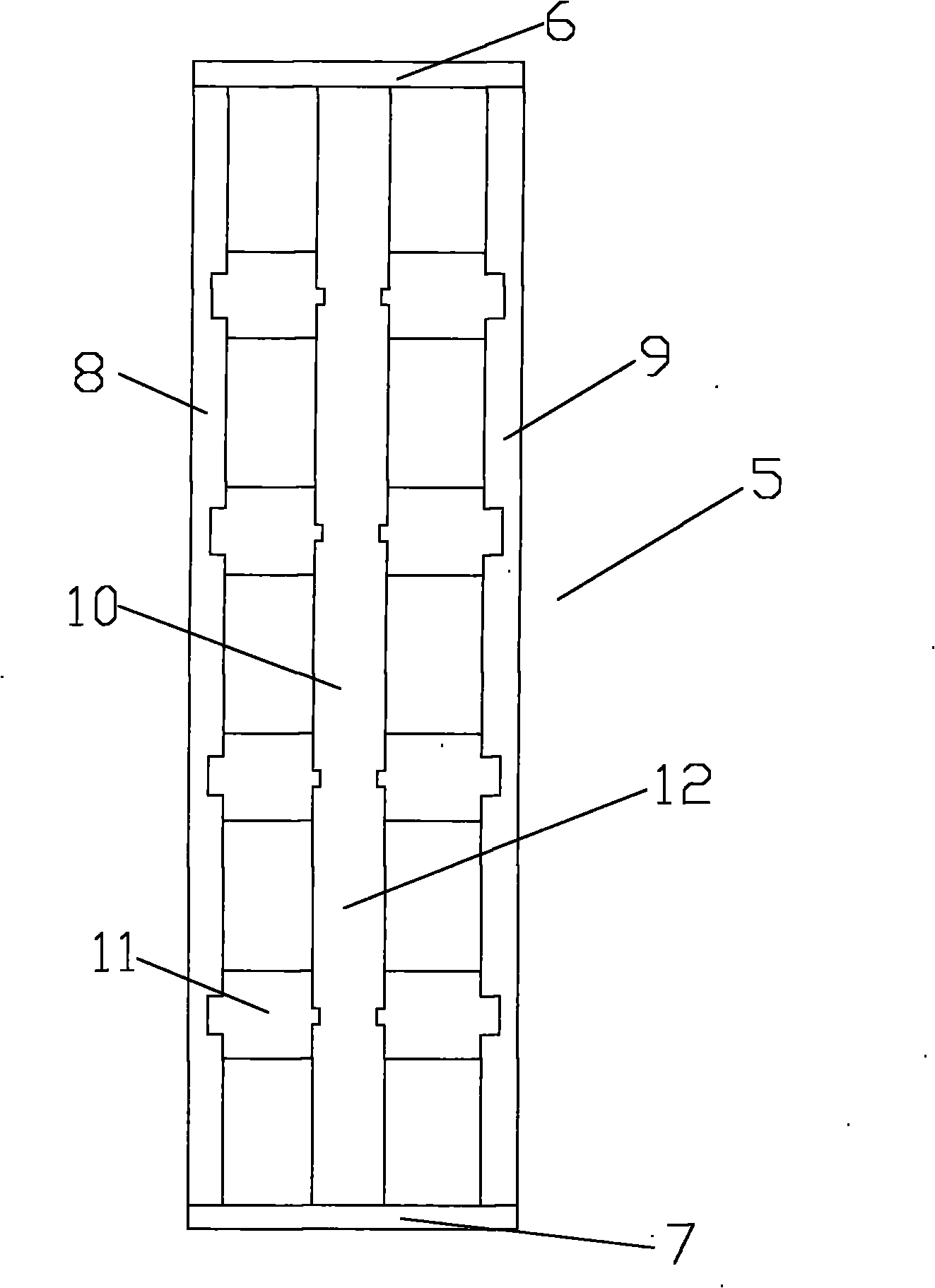

[0015] Such as figure 1 with figure 2 As shown, a floating frame with holes on the sides, the floating frame 5 is placed in the solution of the electroplating tank 3, and the top of the floating frame 5 is provided with a hanger 1 connected to the negative pole of the power supply. The wall is respectively provided with a number of chucks for clamping the plated parts 2, and the clamped plated parts 2 are located under the hanger 1, and a lifting device for controlling the lifting of the hanger 1 is arranged at the front and rear ends of the hanger 1. In the electroplating tank 3, the two sides of the hanger 1 are respectively provided with plating metal 4 connected to the positive pole of the power supply. Such as image 3 As shown, the floating frame 5 is composed of a front fixed plate 6, a rear fixed plate 7, a left anode baffle 8, a right anode baffle 9 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com