Tornado blowing method and cyclone device thereof

A swirl device and tornado technology, applied in the field of purging, can solve the problems of limited effective distance, limited area for effectively stirring dust materials, unfavorable ash unloading operations, etc. The effect of reducing gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

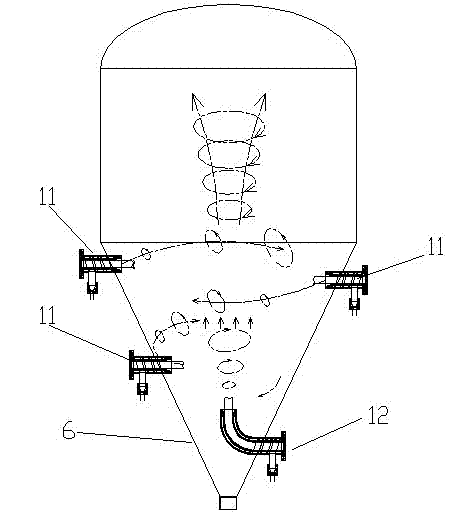

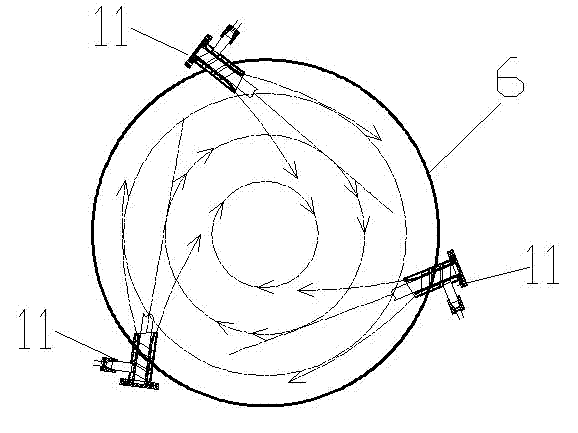

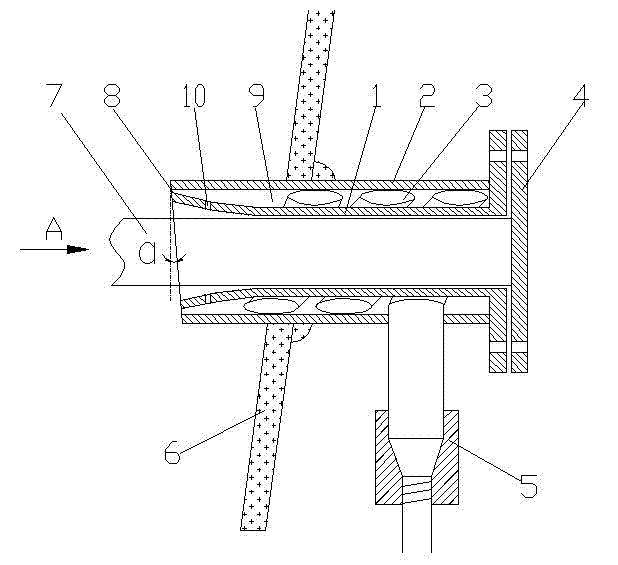

[0030] figure 1 It is a schematic diagram of the formation mechanism of the tornado pattern of the present invention, figure 2 It is a tangential schematic diagram of the formation mechanism of the tornado pattern of the present invention, as shown in the figure: the tornado-type blowing method of the present embodiment performs purge intervention on the stacked materials by spraying the tornado-type disturbance flow; the fluid of the tornado-type disturbance flow is gas , steam, liquid, gas with added particles, steam with added particles, liquid with added particles or a mixture of at least two of them. Adding particles can achieve the beating effect. Liquid is mainly used for dissolving and cleaning solid materials; it can also be used in fluid Internally added agents play the role of chemical dissolution or cleaning; under normal circumstances, inert gas is used to achieve the purpose of interfering with materials and avoid dust explosion; tornado disturbance flow is a to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com