Closure with built-in storing compartment

A technology of closures and compartments, applied in the field of closures, which can solve problems such as production forecasting, planning, waste of pre-filled closures, and difficulty in sanitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

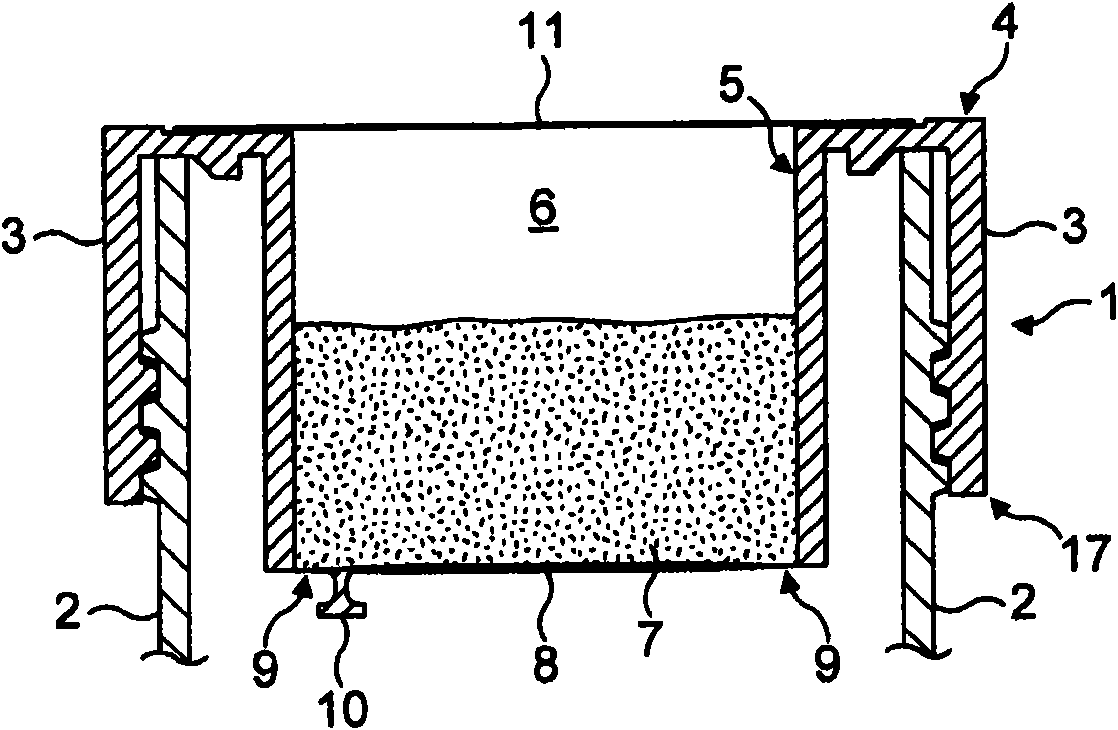

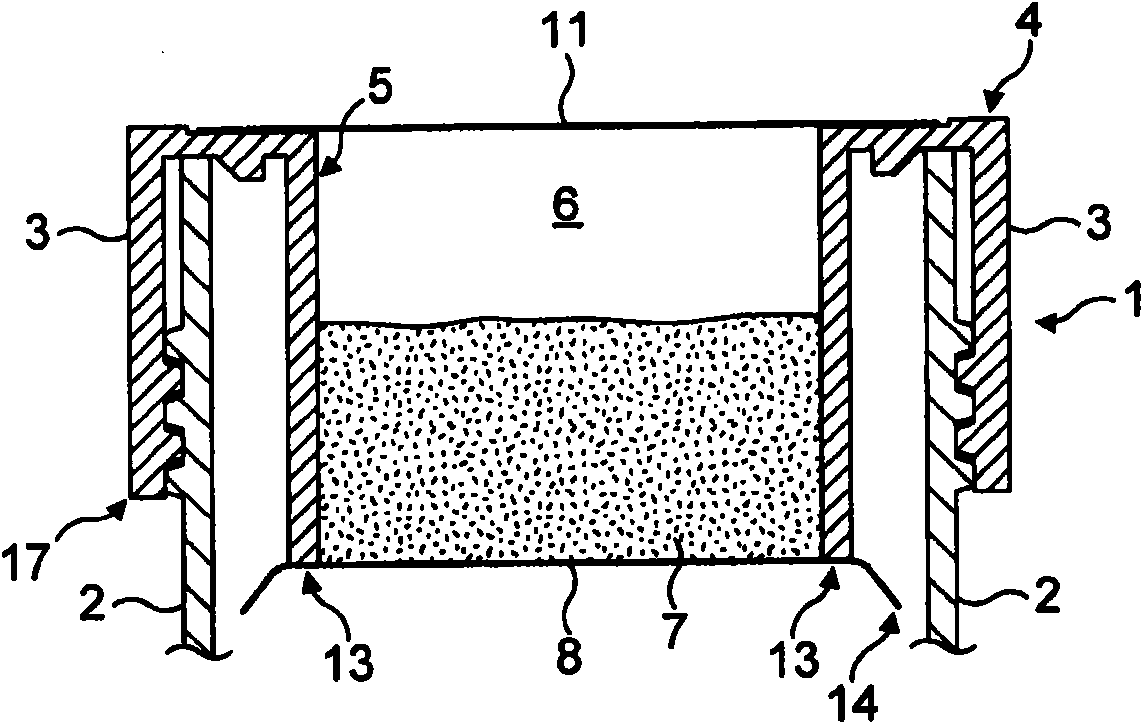

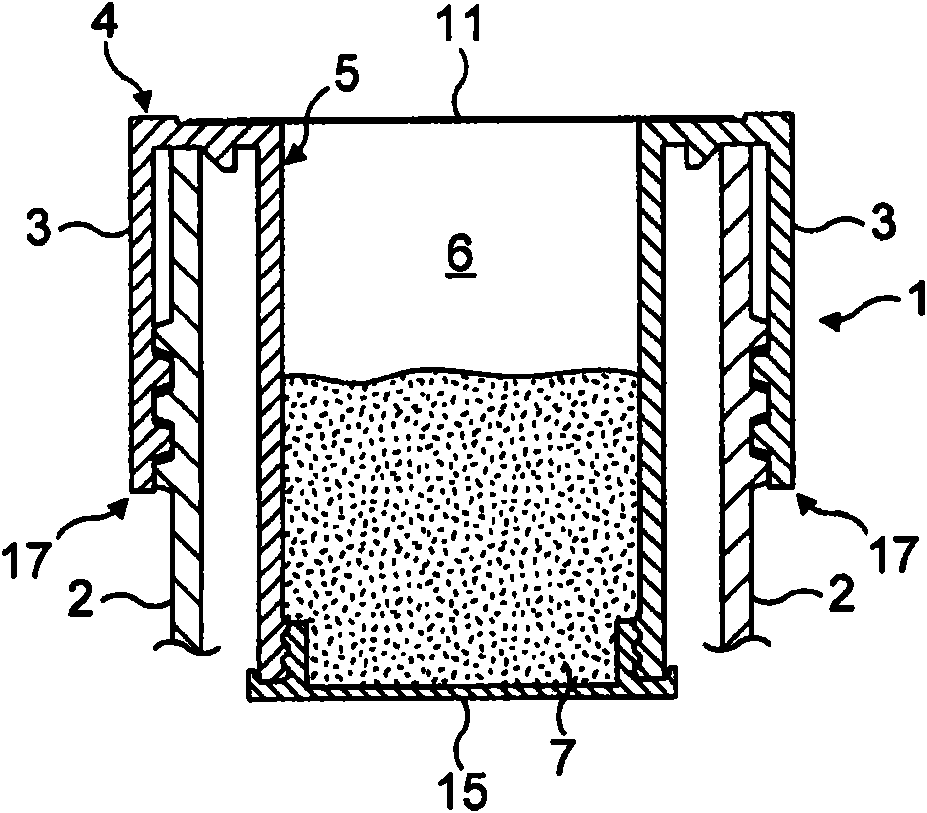

[0042] figure 1 , 2 The closure 1 shown in 3 is adapted to removably close a container containing a first type of product (not shown in the figure). The figure only shows the neck 2 of such a container.

[0043] The closure 1 has an outer side wall 3, a top wall 4 and an inner skirt 5 extending downward from the top wall 4 inside the side wall 3. The inner skirt 5 includes at least one opening. This part of the closure is integrally molded from polypropylene (PP) or polyethylene (PE) by injection molding or compression.

[0044] According to the present invention, the closure 1 includes a closed compartment 6 in the closure for storing the second product 7 separately from the first product.

[0045] The internal volume of the closed compartment 6 is between 1 and 50ml, preferably between 7 and 30ml, more preferably between 10 and 20ml, thereby allowing a certain amount of the second product 7 to be filled-if in powder or granular form , The internal capacity is between 2 and 50g. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com