Belt-type feeder

A feeder and ratchet technology, applied in the direction of electrical components, electrical components, etc., can solve the problems of vibration, flying out, protrusion, and inability to use the adsorption nozzle to absorb, etc., to achieve reliable positioning and stable attitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

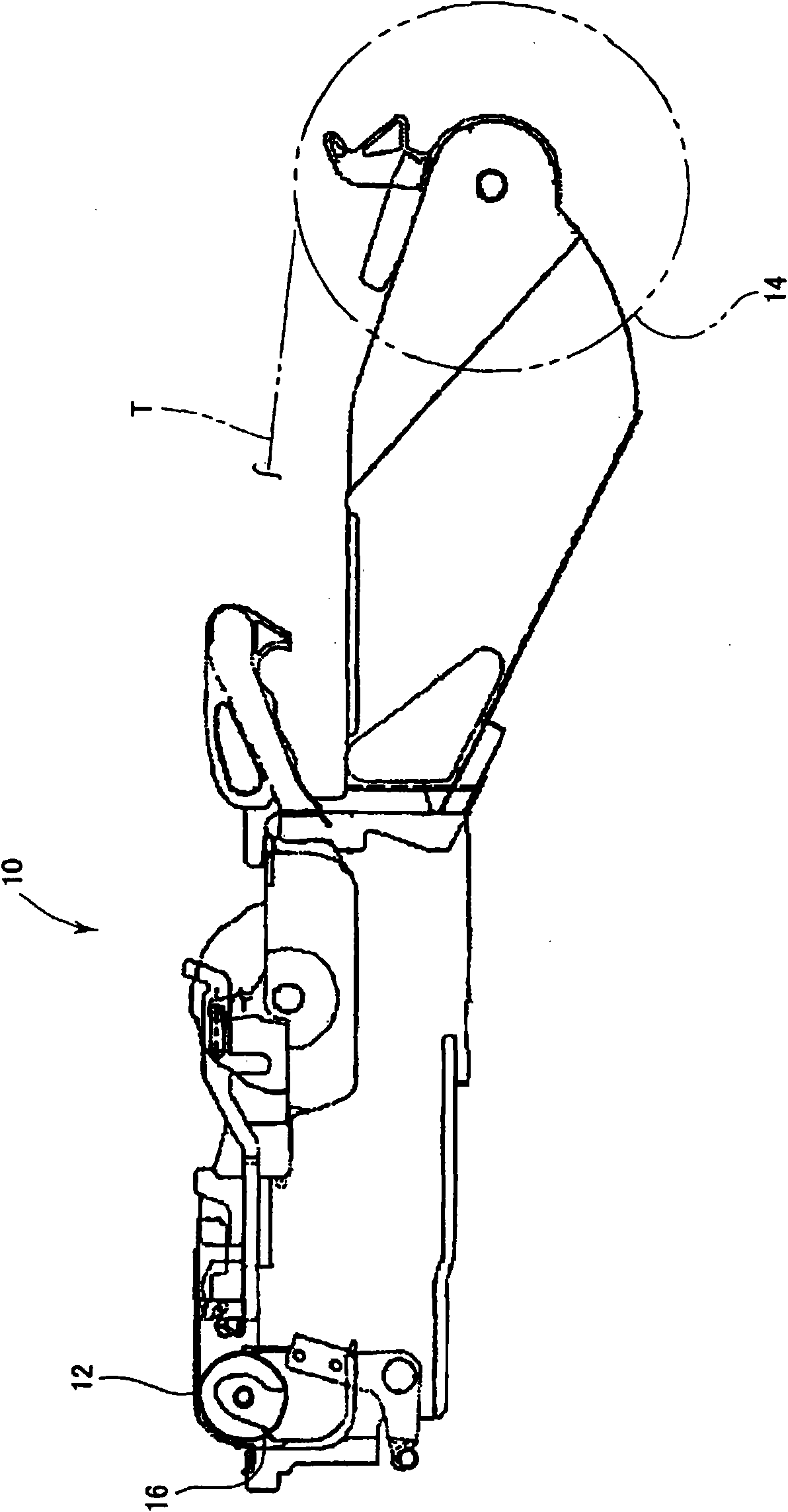

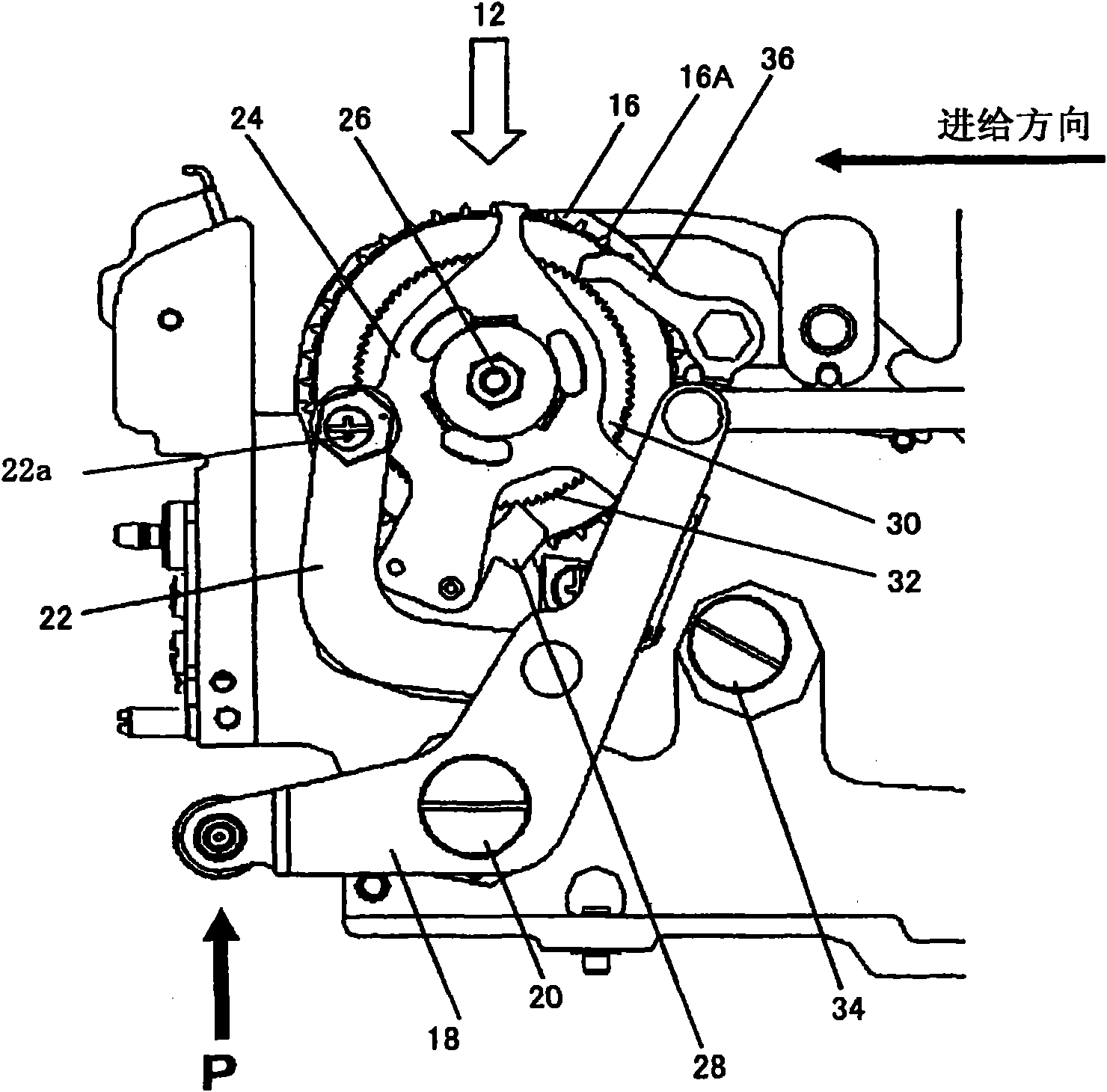

[0040] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0041] The tape feeder 10 of this embodiment is different from the above-mentioned figure 1 , figure 2 The devices shown have the same basic structure. Therefore, detailed descriptions of the same parts are omitted.

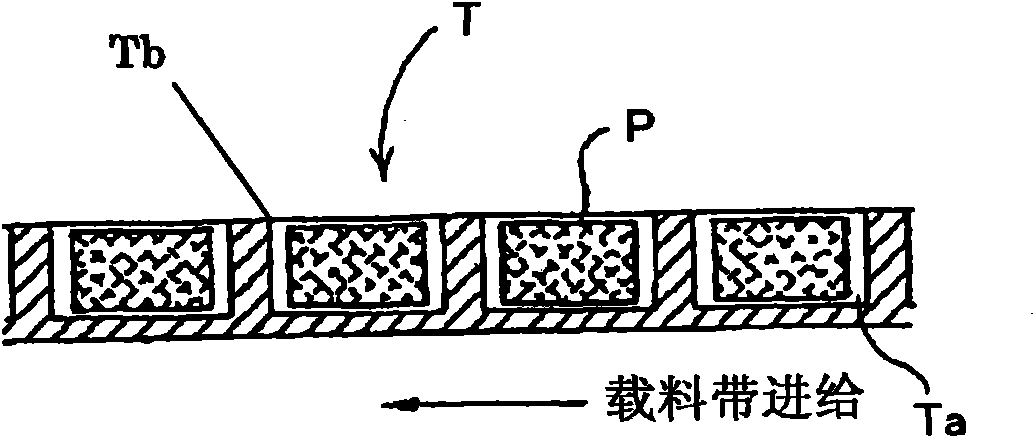

[0042] exist Figure 7 , Figure 8Among them, the above-mentioned stop pawl 36 as a pawl member has an engaging portion 40 at the front end having an engaging surface 43 composed of two planes 41 and 42 intersecting in the front end direction, and the groove-shaped ratchet teeth 32 are formed on the above-mentioned The peripheral end surface 30A of the ratchet 30 is formed at equal intervals, and has a tooth surface 53 composed of two flat surfaces 51 and 52 whose tips intersect in the axial center direction.

[0043] The engaging part 40 of the front end of the ratchet tooth 32 and the stop pawl 36, refer to Figure 9 As shown in (A) and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com