Tightness-adjustable substrate transmission device

A transmission device and substrate technology, which is applied in the direction of transportation and packaging, conveyor objects, electrical components, etc., can solve the problems affecting the life of the roller transmission device, affecting the coaxiality of the roller shaft and the roller, and corrosion of parts, etc., to achieve superior machinery Performance and chemical properties, easy installation, operation and positioning, and the effect of small coaxiality tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

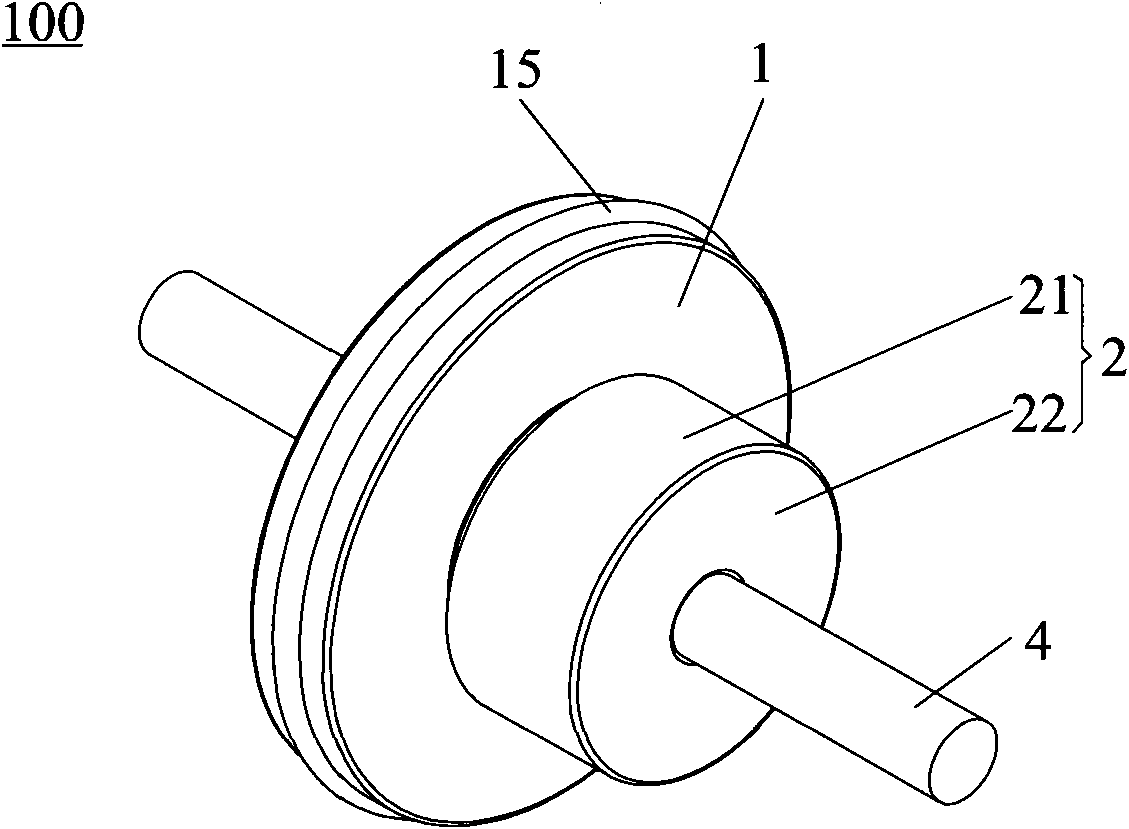

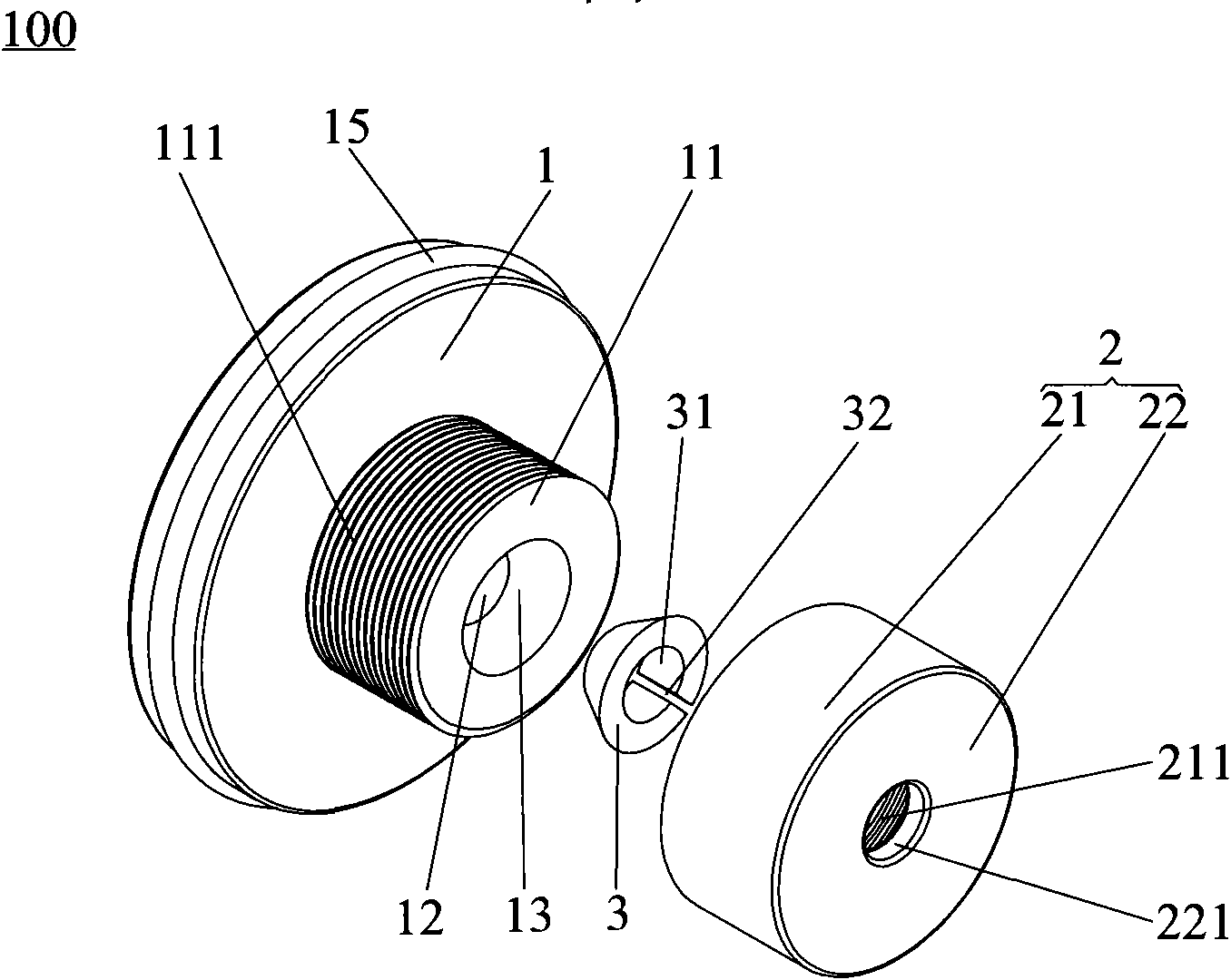

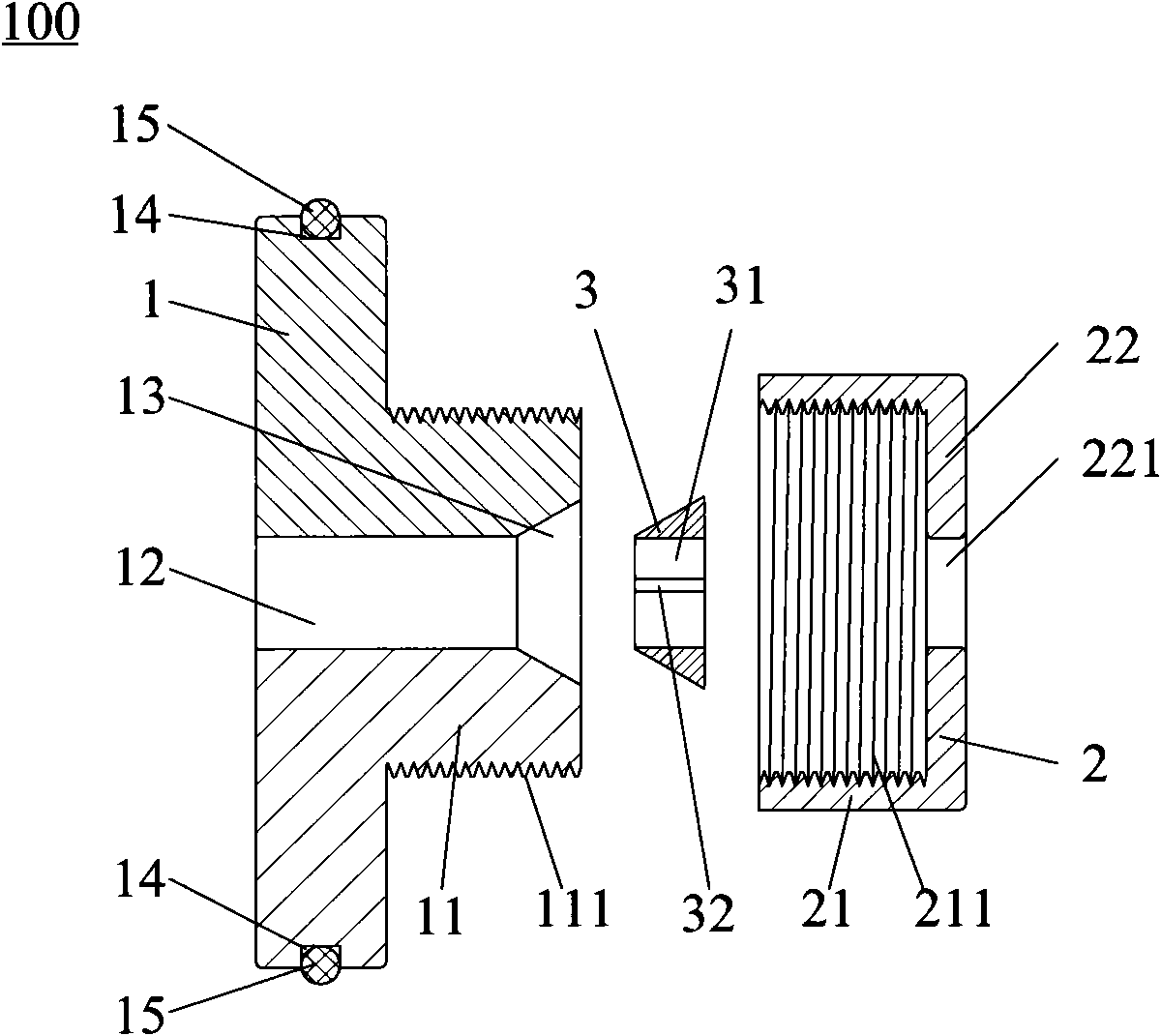

[0020] The adjustable tightening substrate transport device 100 of the present invention is used in the substrate cleaning process made of OLED, and the adjustable tight substrate transport device 100 includes a roller shaft 4 , a roller 1 , a clamping sleeve 3 and a tightening nut 2 . refer to Figure 1-Figure 4 The specific structure of the adjustable and tightenable substrate transfer device 100 of the present invention will be described in detail.

[0021] refer to Figure 1-Figure 4 , the roller 1 is made of engineering plastics, the center of the roller 1 has an inner hole 12 matched with the roller shaft 4, and the center of the right end of the roller 1 protrudes outward to form a connecting part 11 , the outer surface of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com