Decentralized control system for layering controller

A decentralized control system and controller technology, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of multiple inputs, lack of multiple outputs, weak function blocks, and low control efficiency. The effect of controlling risk dispersion, clear correspondence, and improving response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

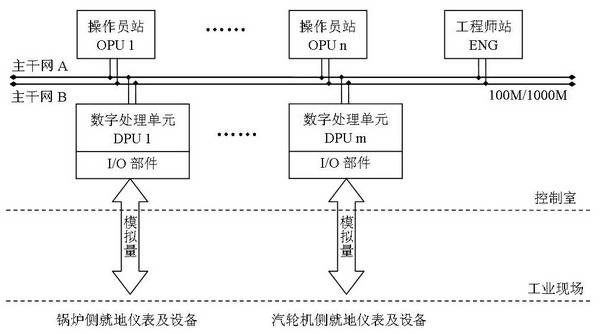

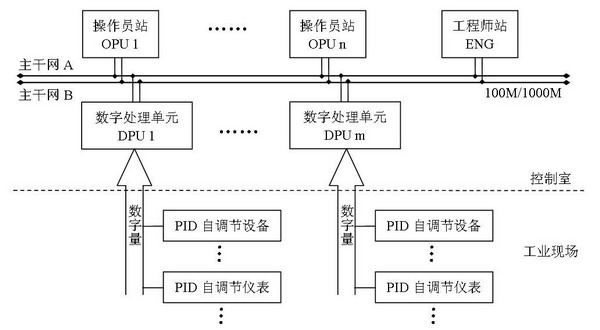

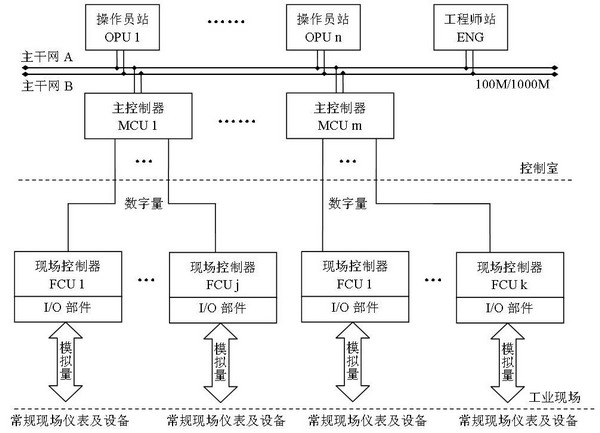

[0051] Such as image 3 As shown, the present invention relates to a distributed control system with hierarchical controllers (hereinafter referred to as FPCS system). Starting from the basic requirements and principles of process control controlled equipment in the process industry, the controlled equipment is subdivided into control units according to the process Several equipment control levels such as group, control unit subgroup, and control unit secondary subgroup. That is, a number of control unit subgroups are connected to each control unit group, and the control parameters of the several control unit subgroups are related to each other, and so on to each equipment control level subgroup.

[0052] The FPCS system of the present invention performs three-dimensional layered processing on the digital processing unit (DPU) in the existing control system, and sets several layers of control units to correspondingly monitor the above-mentioned several equipment control levels. H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com