Quasi-two-stage compression ultralow temperature air source heat pump water heater with economizer

An air source heat pump and economizer technology, which is applied in refrigerators, fluid heaters, evaporators/condensers, etc., can solve the problems of inability to meet the heating demand in winter, the reduction of the heating COP of the unit, and the impact on the service life of the compressor. To improve the anti-frost ability, improve the energy efficiency ratio, and achieve the effect of good defrosting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

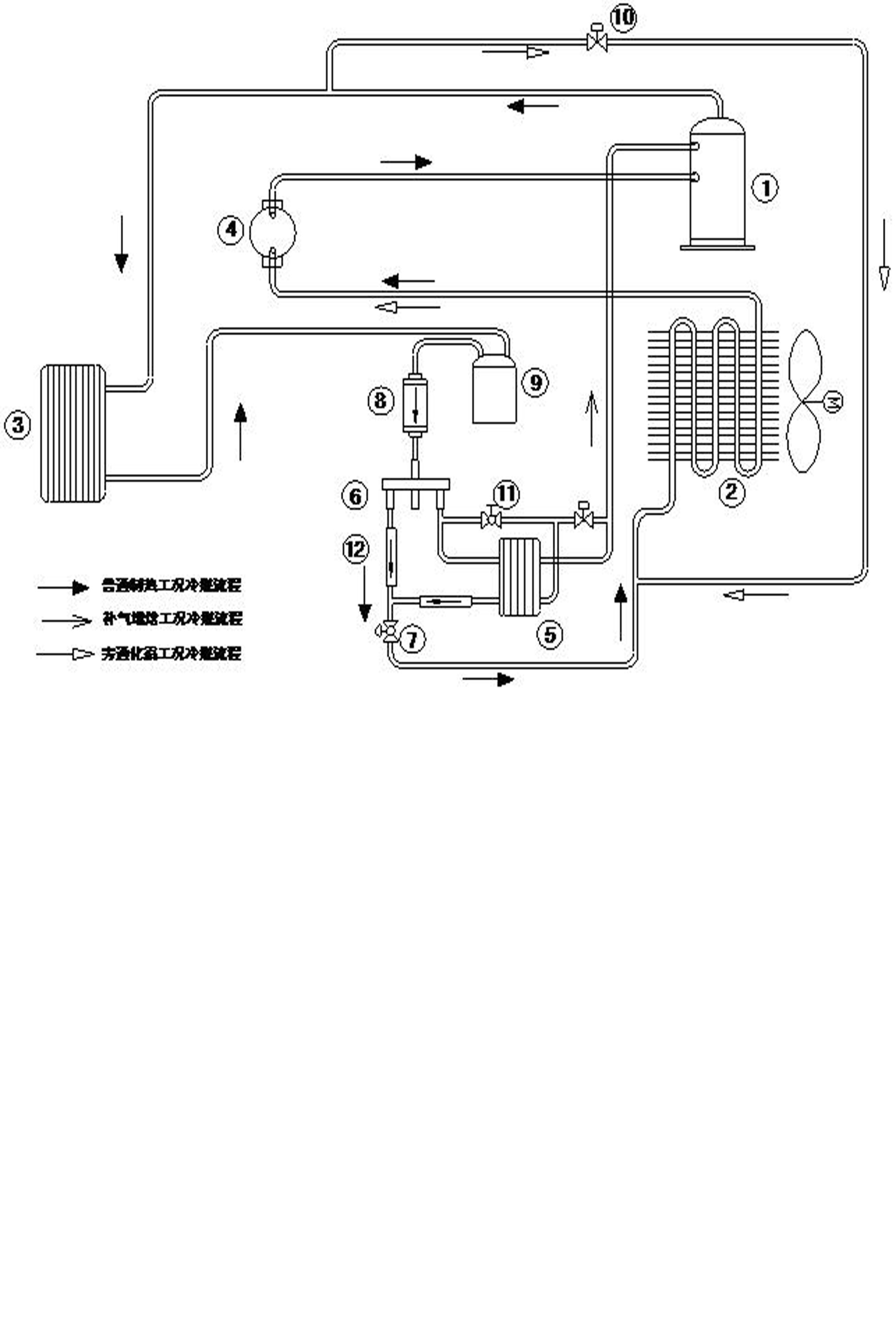

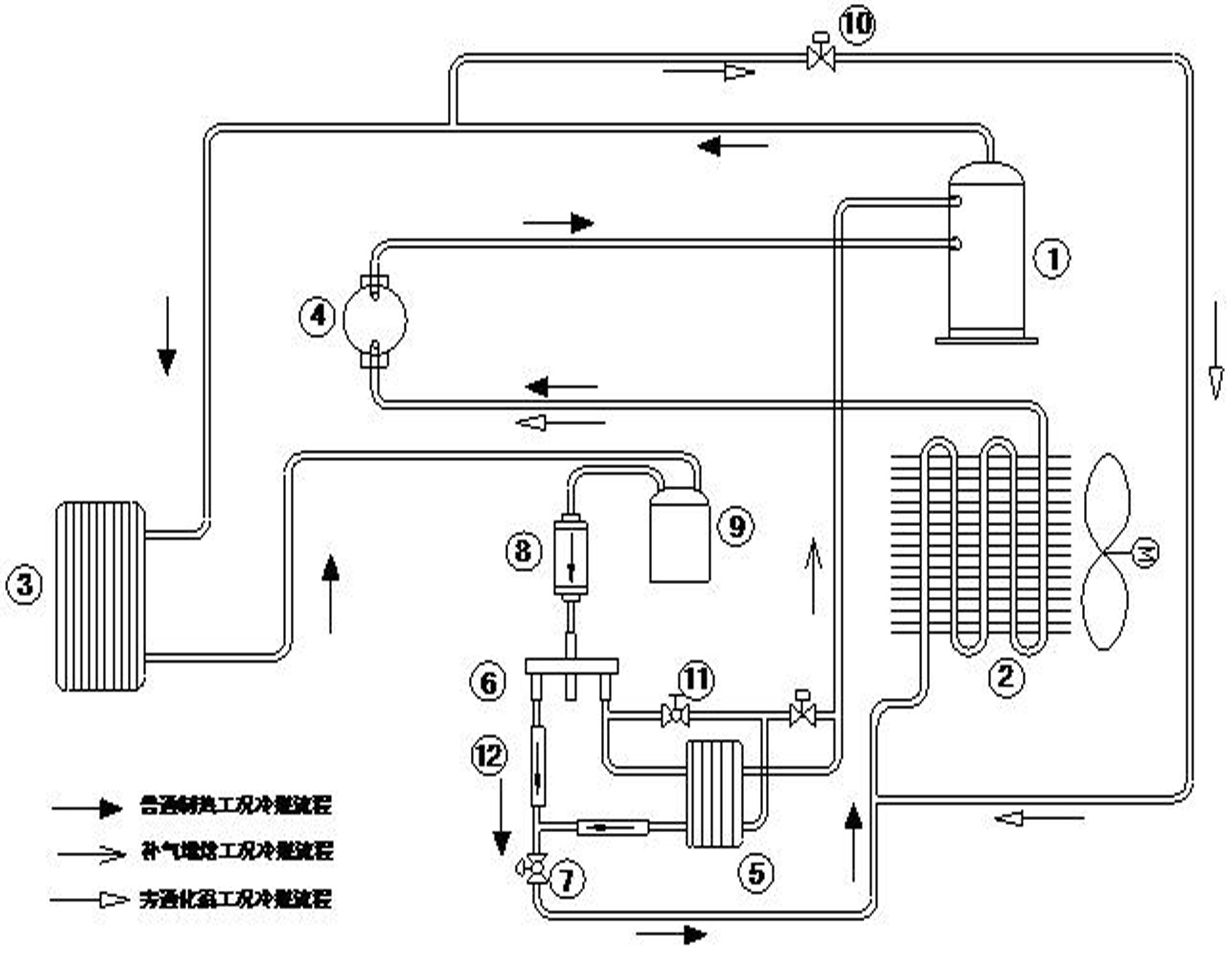

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] Depend on figure 1 It can be seen that the quasi-two-stage compression ultra-low temperature air source heat pump water heater with an economizer is mainly composed of a compressor 1, an air-cooled evaporator 2, a water-side heat exchanger 3, a gas-liquid separator 4, an economizer 5, Four-way valve 6, electronic expansion valve 7, dry filter 8, liquid receiver 9, solenoid valve 10, thermal expansion valve 11 and one-way valve 12, use refrigerant as refrigerant, consume a small amount of high-grade electric energy to absorb low-temperature in the air The specific connection method is as follows: According to the flow direction of the refrigerant, the exhaust pipe of the compressor 1 is connected with the water-side sleeve heat exchanger 3, and then connected with the liquid receiver 9, and the connection of the liquid receiver 9 The liquid outlet pipe is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com