Gas and oil canister combined non-isolated multiple piston accumulator

A non-isolation and accumulator technology, applied in the direction of mechanical equipment, etc., can solve the problems of slow response speed of the system, short life of the upper seal, increased frictional resistance, etc., and achieve fast response speed, slow response speed and large diameter Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

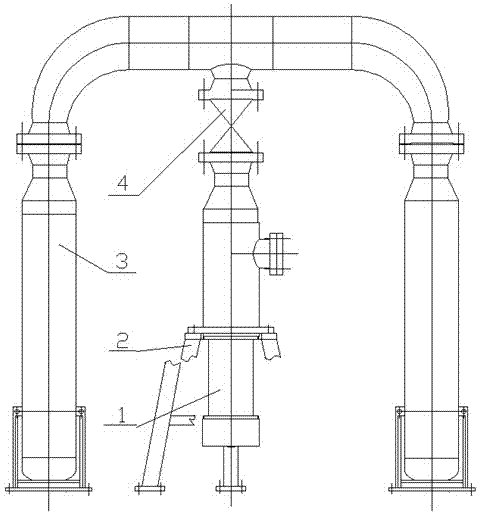

[0042] Such as figure 1 It is a schematic diagram of a non-isolated multi-type piston accumulator combined with gas and oil tanks. It consists of oil tank 1, oil tank bracket 2, air tank 3 and high pressure ball valve 4. The part of the oil tank 1 is provided with an oil tank support 2, a high-pressure ball valve 4 is arranged above the oil tank 1, and an air tank 3 is arranged above the high-pressure ball valve 4 and is connected with the flange 7 on the gas tank 3. The oil tank 1 has an oil tank structure with a magnetostrictive displacement sensor and an oil tank structure with a magnetic induction proximity switch. The gas tank has an inverted mountain shape, an annular two-body seat type, an annular four-body seat type and a T-shaped structure. They can be combined into eight types of piston accumulators with different capacities.

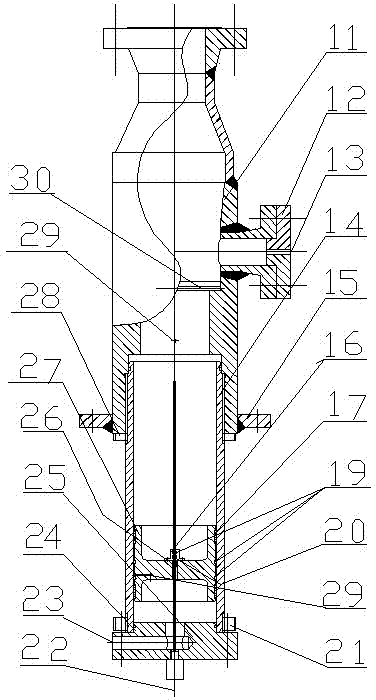

[0043] Such as figure 2 As shown, the air container 3 is an inverted mountain-shaped air container, including the air container body...

Embodiment 2

[0047] The difference between this embodiment and Embodiment 1 is that this embodiment adopts a schematic structural diagram of an oil tank with a magnetic induction proximity switch, as shown in Figure 4 As shown, most of its structure is the same as image 3 The oil tank with a magnetostrictive position sensor is the same, the difference lies in the relevant parts caused by the installation of the magnetic induction proximity switch 32, which is described as follows; the top of the aluminum alloy piston 27 is provided with a proximity switch trigger body 18, and the connector 11 is connected to the oil tank. Near the contact of 14, a magnetic induction proximity switch 32 is provided, and a magnetic induction proximity switch 32 is also installed on the oil tank seat 25. The guide shaft at the bottom of the aluminum alloy piston 27 also acts as a trigger body for the proximity switch. When the oil and replenishing oil are full, a signal is sent, and the magnetic induction p...

Embodiment 3

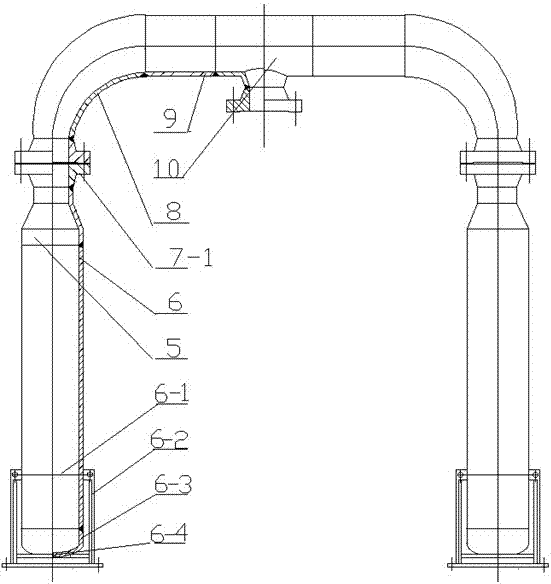

[0050] Such as Figure 5 and Figure 6 As shown in , it is a schematic structural diagram of a non-isolated low-pressure-difference inverted mountain-shaped piston accumulator combined with gas and oil tanks. Including the gas tank 6, the lower part of the gas tank 6 is welded with an inherent spherical head 6-3, the bottom of the spherical head 6-3 is provided with a sewage outlet 6-4, and the upper part of the gas tank 6 is provided with a first flange 7- 1. A different-diameter elbow 8 is provided above the first flange 7-1, a seamless steel pipe 9 is provided on the side of the different-diameter elbow 8, and a different-diameter tee 10 is provided on the side of the seamless steel pipe 9 , a flange 7 is provided at the lower part of the reducing tee 10 trails. Other structures and working methods of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com