Synchronous rolling device of thin material punching machine

A thin material, punching machine technology, applied in the direction of thin material processing, coiling, transportation and packaging, etc., can solve the problem of cutting waste, etc., and achieve the effect of accurate transmission, stable transmission and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

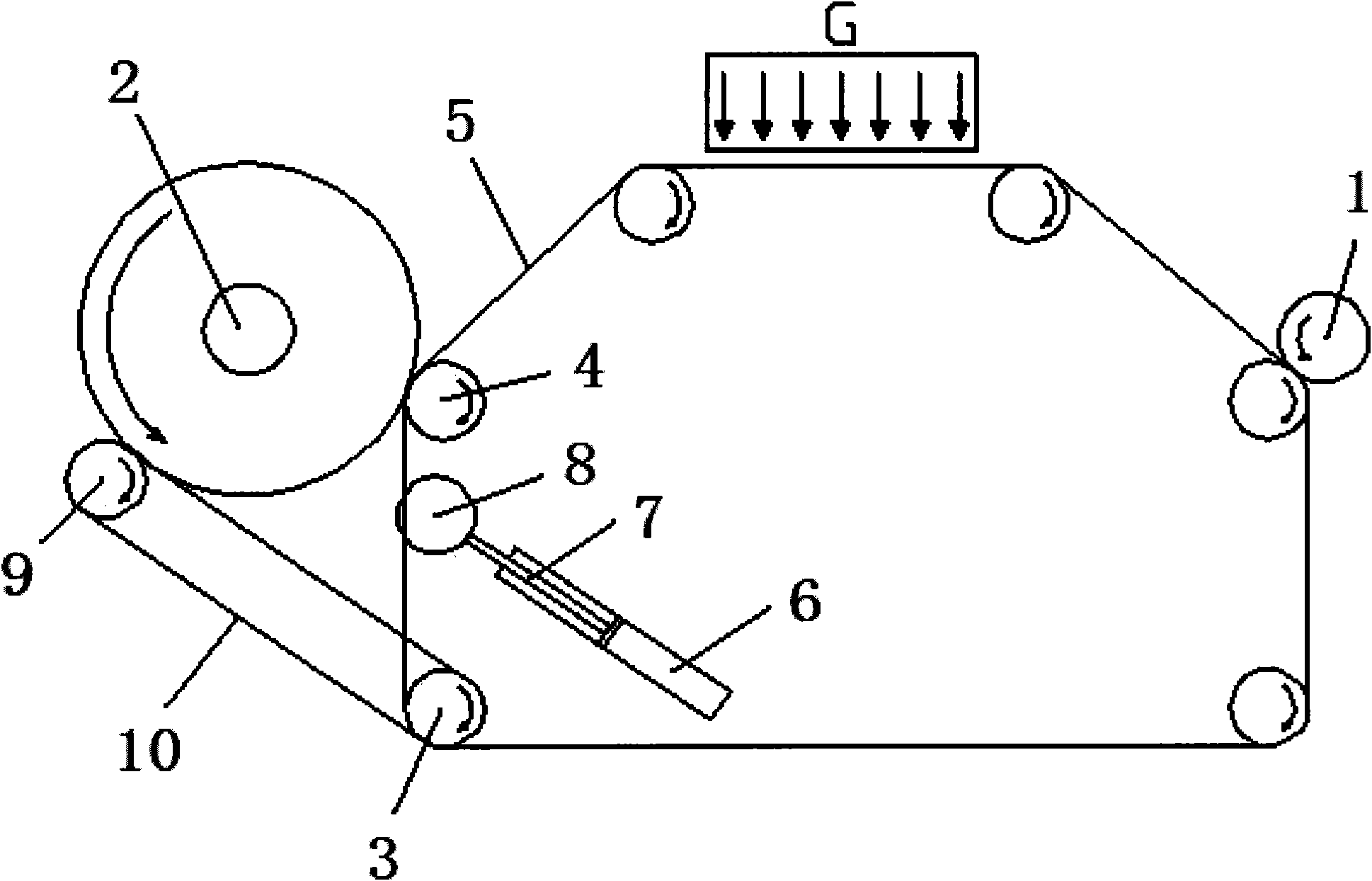

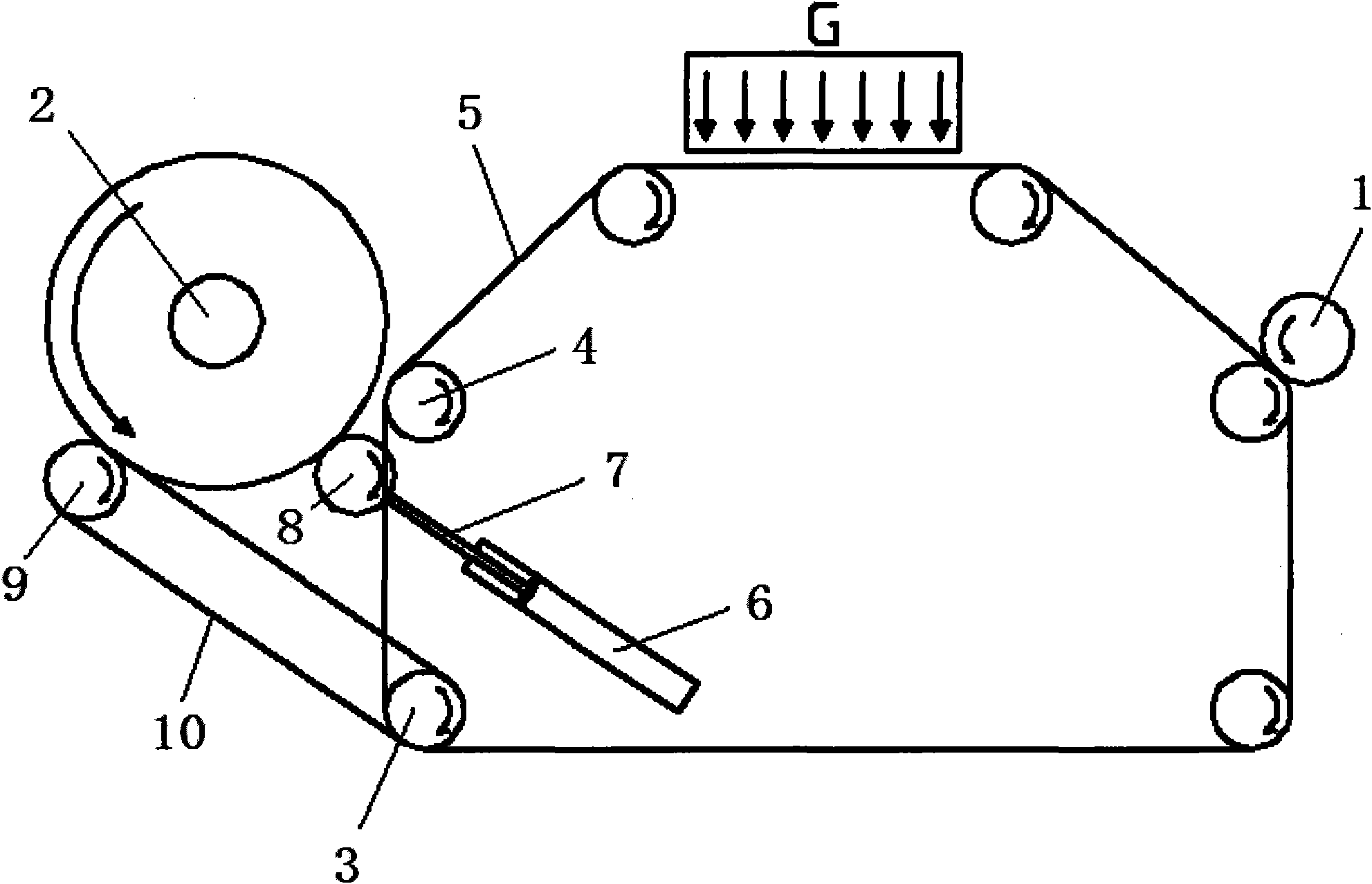

[0022] Example: Combine figure 1 , figure 2 As shown, the synchronous unwinding device of the thin material punching machine provided in this embodiment is specifically used for laser punching of tipping paper, and needs to be used in conjunction with the tipping paper laser punching machine, which mainly includes a winding shaft 1 and an unwinding shaft 2. Synchronous pulley paper feeding mechanism, unwinding shaft drive mechanism, auxiliary support pulley 9 and auxiliary circular conveyor belt 10.

[0023] Such as figure 1 , figure 2 As shown, the synchronous pulley paper feeding mechanism in this embodiment adopts a driving pulley 3 and five driven pulleys 4 arranged in a trapezoidal structure, wherein the driving pulley 3 is located at the lower left foot, and it is driven by a motor to rotate. And the periphery of each pulley then tensions the main circulation conveyor belt 5, and the said main circulation conveyor belt 5 passes through the punching area G on the tip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com