Magnetomechanical connection assembly with load securing

A connection structure and magnetic connection technology, which is applied in the field of locks, can solve problems such as affecting the opening tactile sensation of locks and making it difficult to close.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

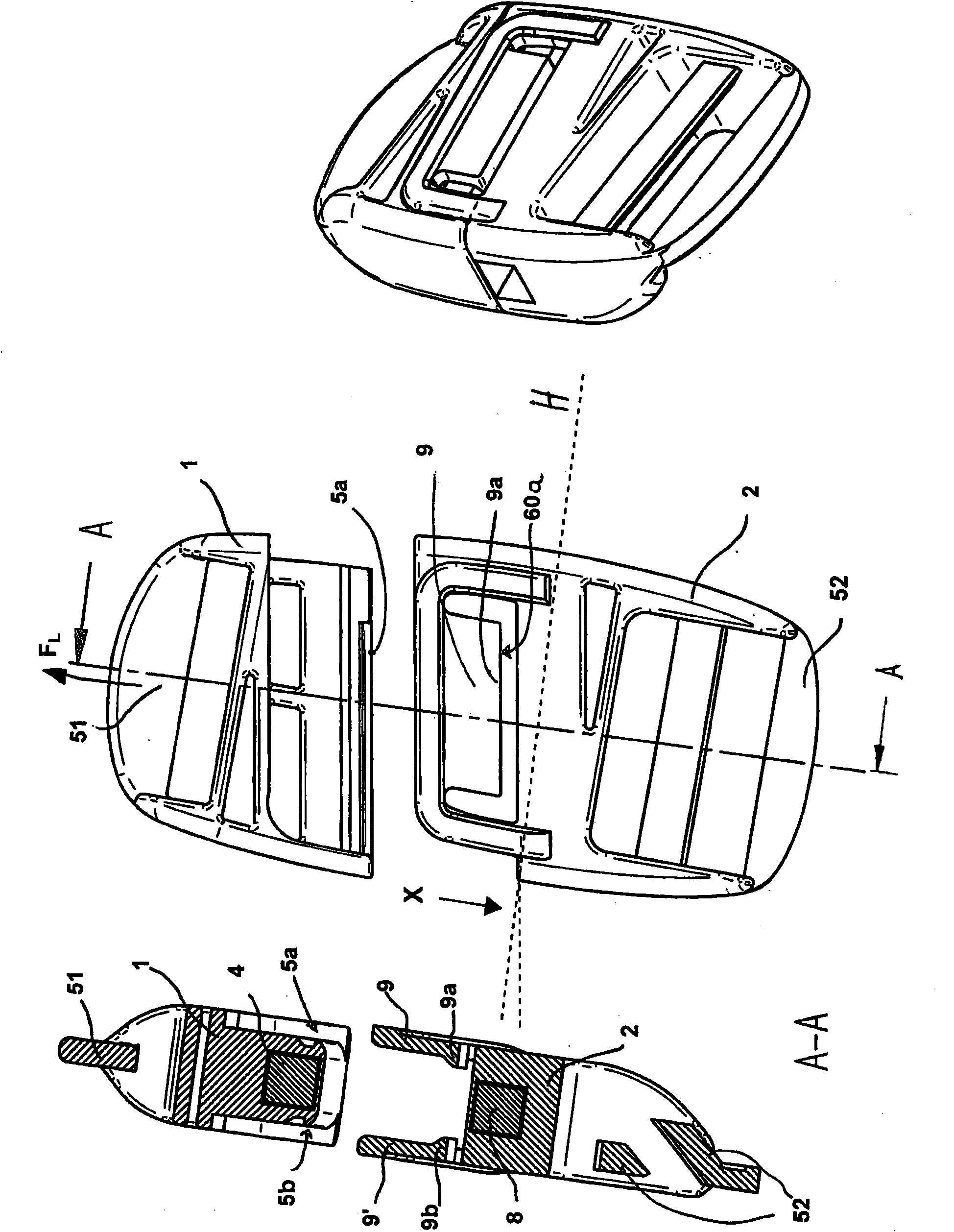

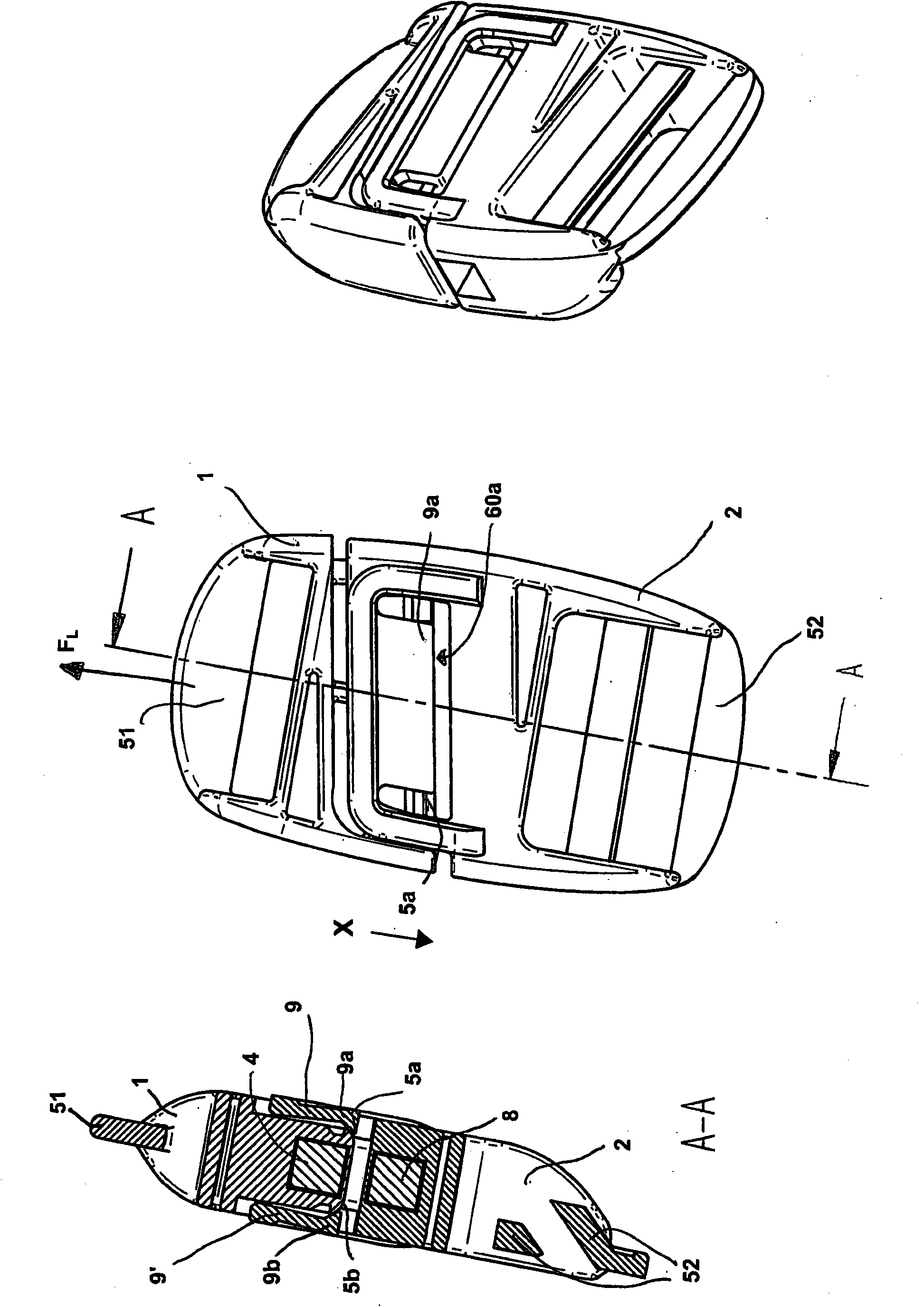

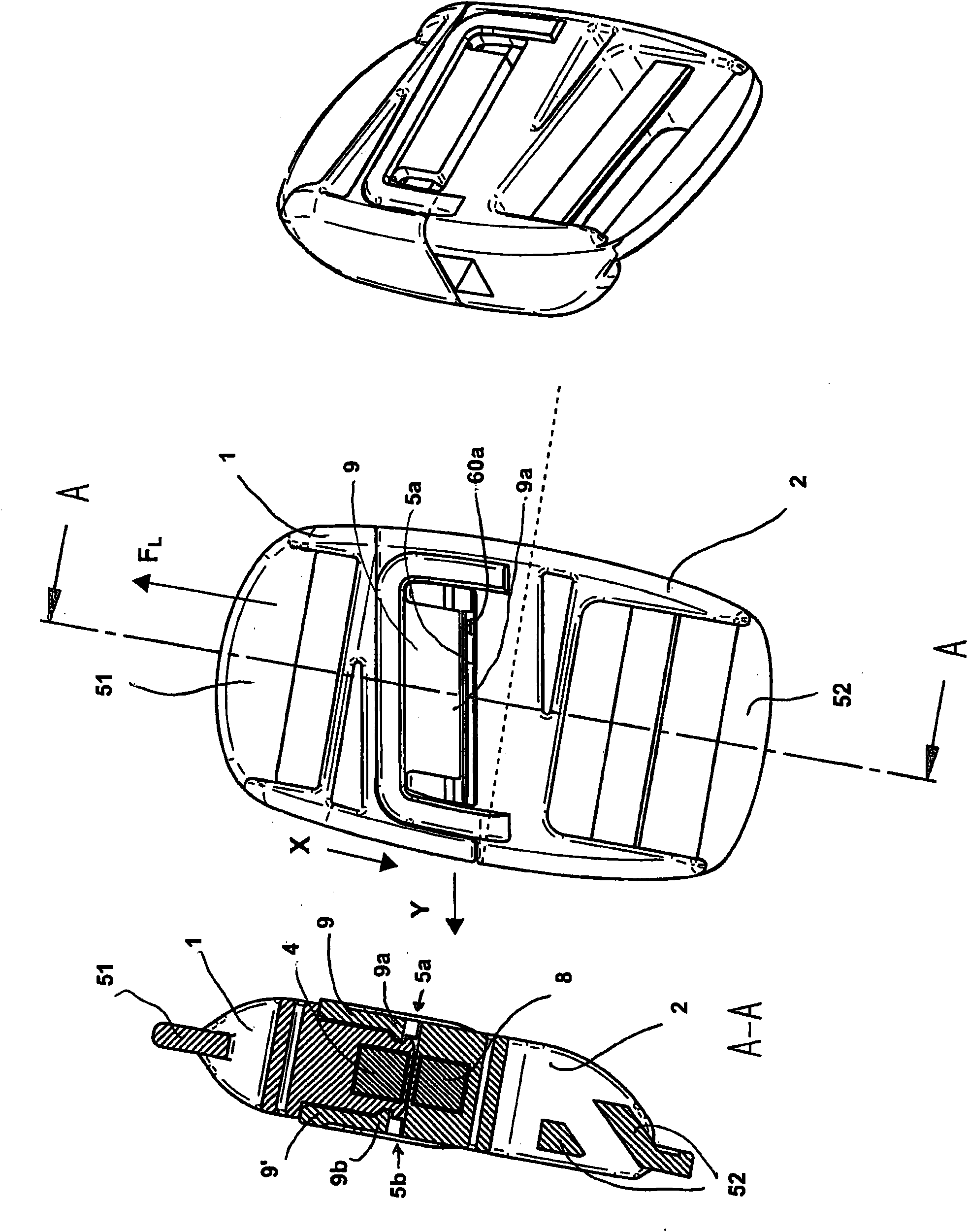

[0089] In comparison, the principle according to the invention will firstly be explained in terms of the functions and effects that occur in a magnetic closure according to the prior art according to document EP 97921465 .

[0090] Figures 10a to 10c The structure and function of the hook-shaped closure during closing and opening are shown in diagram form. The closure is contained in each connection module 1 and 2 , which has magnets 48 and 80 and connection means in the form of tongue 74 and base 38 , respectively.

[0091] Figure 10a From left to right, the physical work that must be applied when the closure is closed under load is shown in the two motion phases.

[0092] Starting from rest, the connection module 2 first overcomes the downwardly directed force F L is lifted from the separated position to the height P0, for which work W is required Δy . The height P0 is the height position that the connection module 2 also has in the hooked state. Since the magnetic f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com