Reduction of temperature influence caused by pressure of sound velocity in gas

A technology for gases and gas mixtures used in material analysis, measuring devices, instruments, etc. using sonic/ultrasonic/infrasonic waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

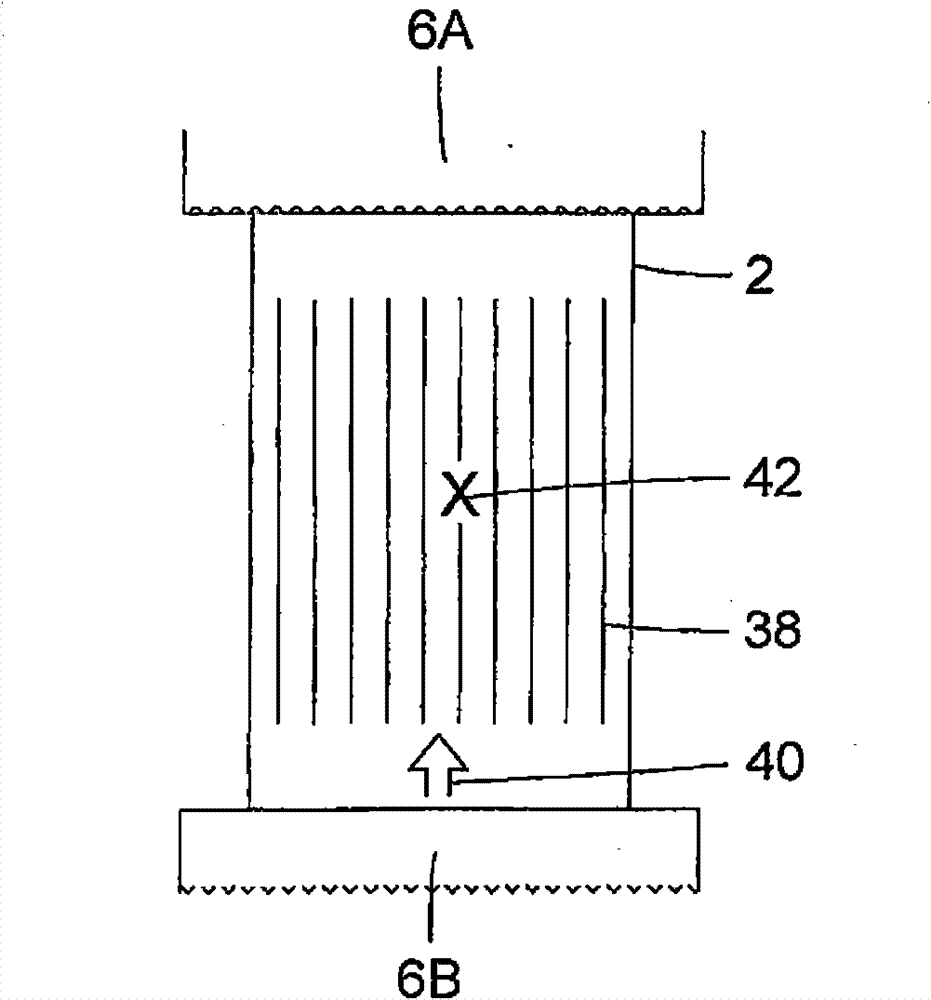

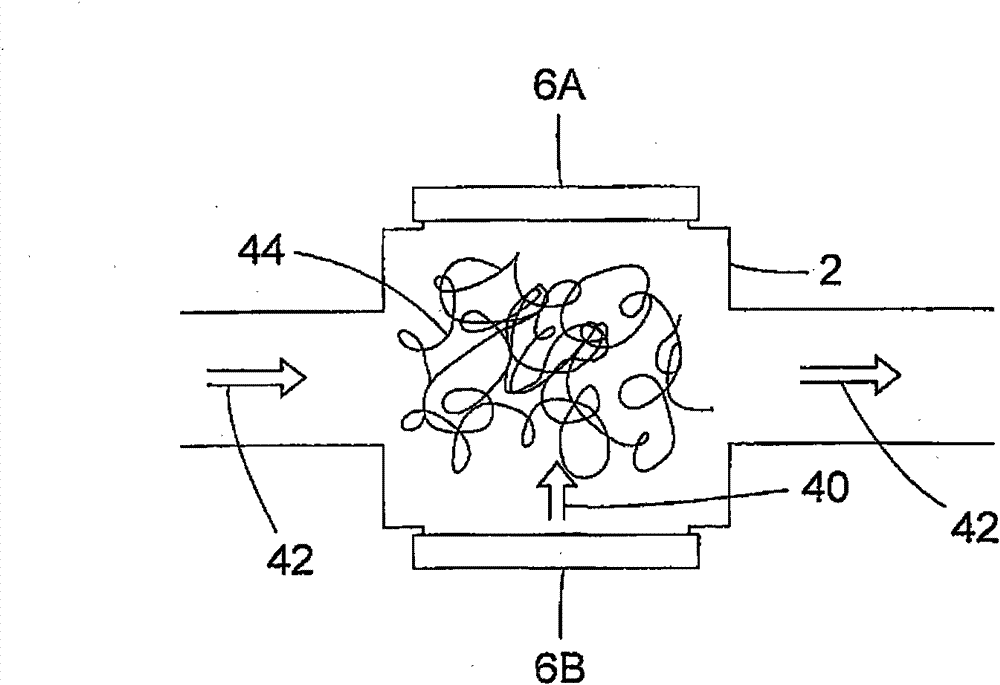

[0073] Measuring chamber

[0074] In a preferred embodiment, the invention is realized by means of a measuring chamber for temporarily containing the gas to be measured. Preferably, the chamber is mounted such that a gas flow passes through the chamber and measurement sampling is intermittently performed on the flowing gas. A functional requirement for the measuring chamber is that the chamber-defining substance should act as a thermal buffer and have an efficient heat exchange with the gas molecules. The higher the achieved heat exchange efficiency, the more the speed of the temperature equilibration process increases and the better the effect of the invention.

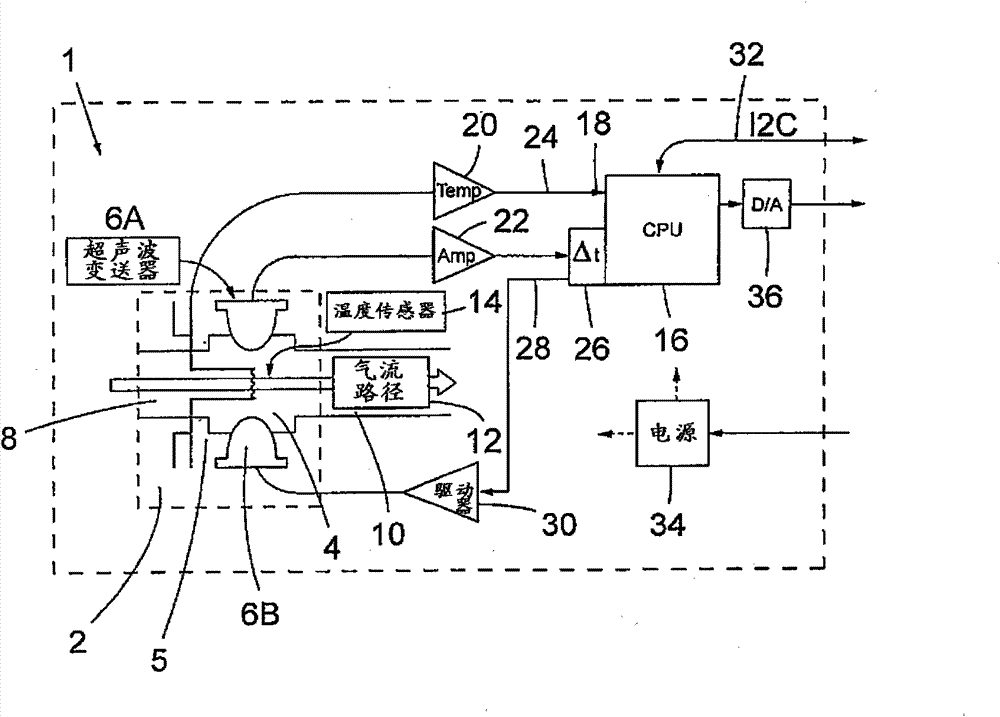

[0075] figure 1 A measuring device 1 according to the invention is shown schematically. The measuring chamber 2 defined by the chamber-defining structure 5 has a cavity 4 with a space of gas in which ultrasonic waves propagate from the ultrasonic transmitter to the ultrasonic receiver. exist figure 1 In the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com