Method for optimizing Parsytec on-line surface defect detection system

A surface detection and system optimization technology, applied in the field of thin plate rolling, can solve the problems that the detection system cannot stably improve the detection and judgment capabilities, cannot participate well, and lacks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

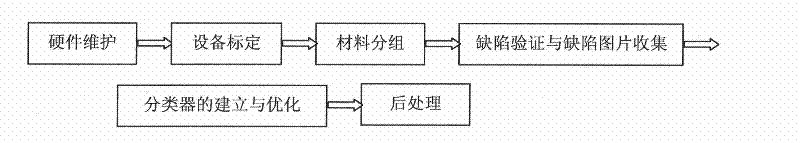

[0063] Example 1 Establishment and optimization of a warping defect classifier for cold-rolled base material

[0064] The Baishitai online surface defect detection system on the 2160 hot rolling production line of Shougang Qiangang has been debugged and optimized. The hardware maintenance and equipment calibration are as described in steps (1) and (2). This case focuses on the description of the material group as cold rolling The process of collecting warped skin defect pictures of the base material and establishing and optimizing the classifier.

[0065] (1) Defect verification and collection of typical defect samples

[0066] When carrying out defect verification, a large number of defect verifications have been carried out for edge warping defects. Figure 5 It is a typical picture of warped skin defects detected by Bepsitech system, attached Figure 6 to attach Figure 5 The real photo of the defect in the corresponding part of the steel coil. After it is determined th...

example 2

[0078] Example 2 Establishment and optimization of roll printing defect classifier for cold-rolled base material

[0079] The Baishitai online surface defect detection system on the 2160 hot rolling production line of Shougang Qiangang has been debugged and optimized. The hardware maintenance and equipment calibration are as described in steps (1) and (2). This example focuses on the description of the material group as cold rolling The process of collecting images of roll printing defects of the base material and establishing and optimizing the classifier.

[0080] (1) Defect verification and collection of typical defect samples

[0081] When roller printing defects occur, collect samples, and for the same roll of roller printing defects, collect no more than 2-3 roller printing defects. attached Figure 8 It is a typical roller printing defect.

[0082] (2) Build a classifier

[0083] When the number of roll printing samples reaches about 100, the defect features are suf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com