Method for measuring temperature of inner ring and outer ring of bearing between double-rotor engine rotors

A dual-rotor engine, inner and outer ring technology, applied in the field of aero-engines, can solve problems such as difficulty in reading data and oil mist interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

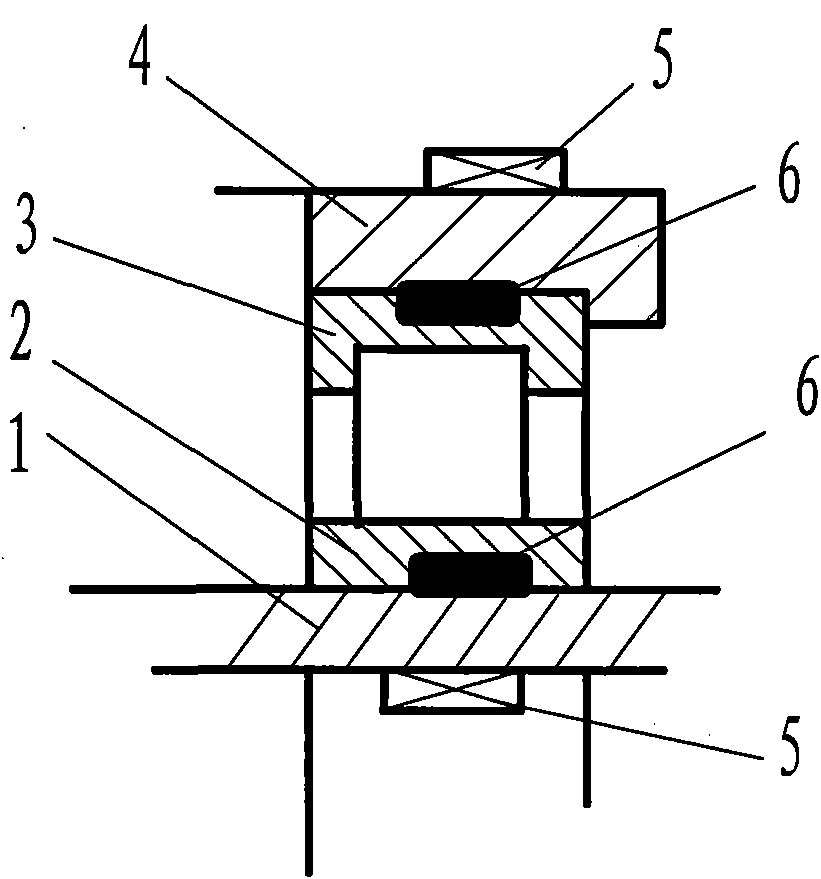

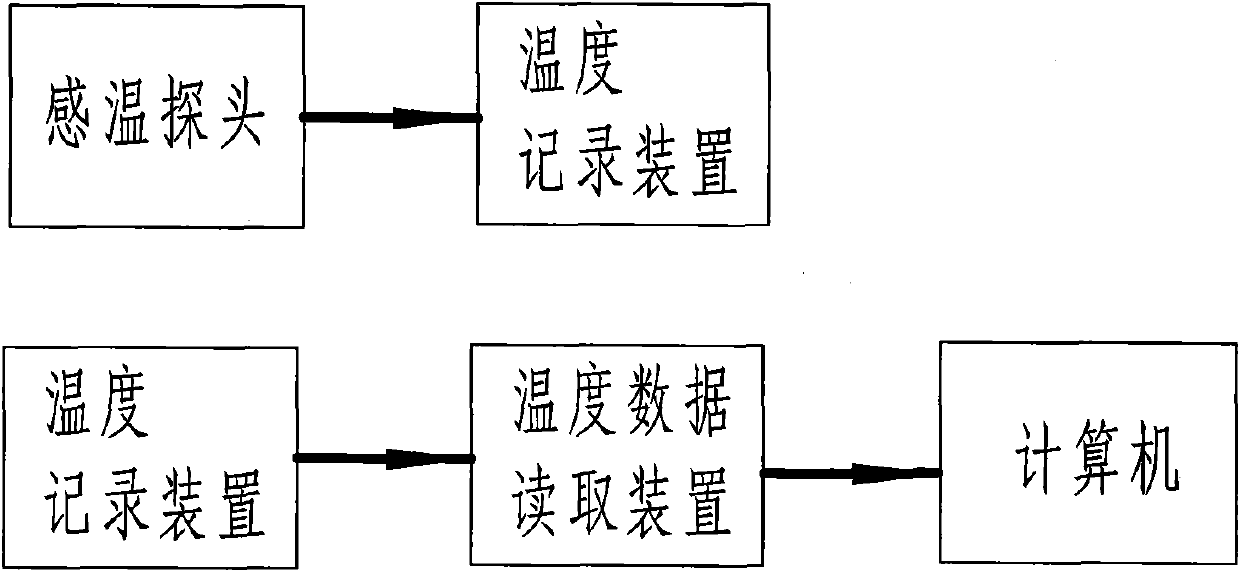

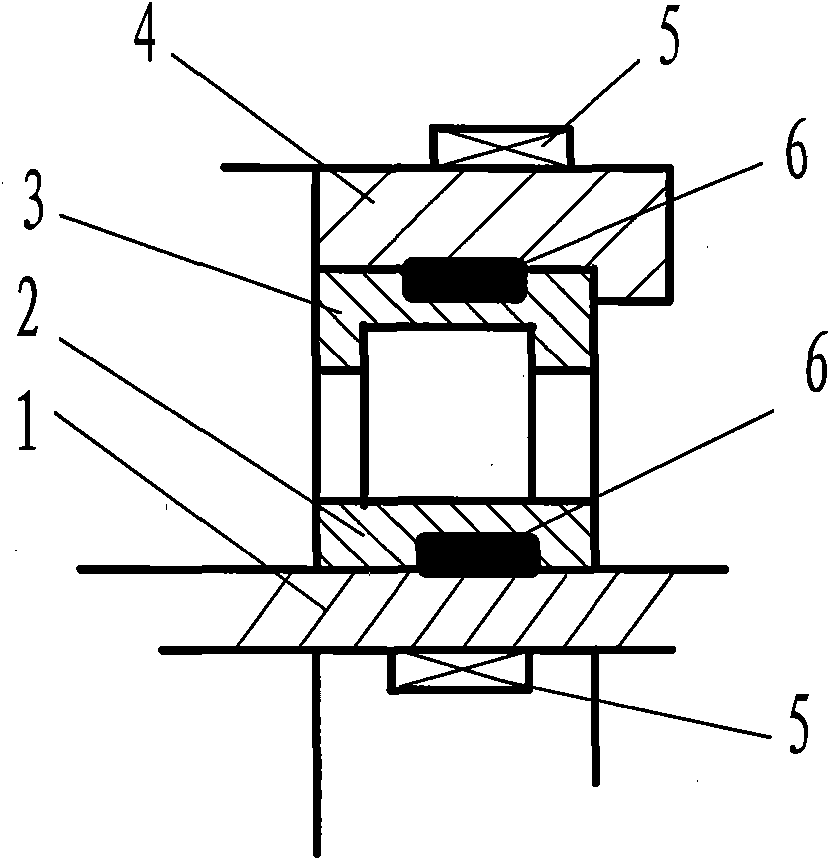

[0011] The method for measuring the temperature of the inner and outer rings of the inter-rotor bearing of the dual-rotor engine of the present invention will be specifically described below in conjunction with the accompanying drawings.

[0012] Such as image 3 As shown, the temperature recording device 5 is first wrapped with airgel, and then fixed on the rotor shaft 1 or the outer rotor mounting seat 4 of the engine with screws, and the temperature sensing probe 6 is implanted on the inner ring 2 of the bearing or the outer ring 3 of the bearing, Make the sensitive part of the temperature probe 6 close to the inner ring 2 of the bearing or the outer ring 3 of the bearing.

[0013] After the rotor of the engine starts to rotate, the temperature sensing probe 5 and the temperature recording device 3 will rotate with the rotor shaft 1 at an equal angular velocity. When the rotation speed of the rotor shaft 1 is greater than 3000 rpm, the temperature recording device 3 will be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com