Force bearing device three-dimensionally adjusted and positioned by unitized curtain wall

A three-dimensional adjustment and unit-type technology, applied to walls, building components, buildings, etc., can solve problems such as low efficiency, complex processing technology, and inappropriateness, and achieve the effect of reducing labor intensity, simple processing procedures, and exquisite structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The description will be further described below in conjunction with specific drawings and examples.

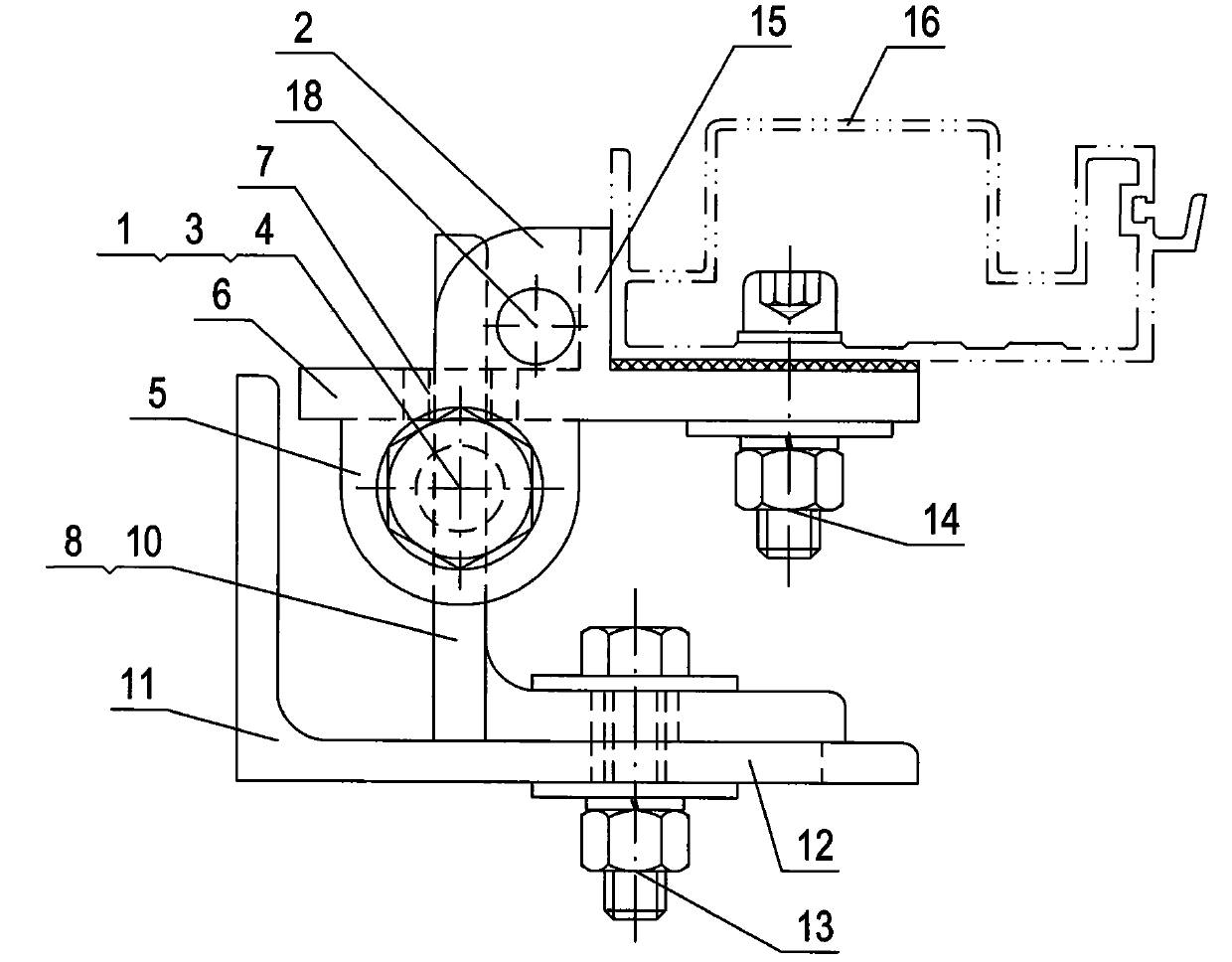

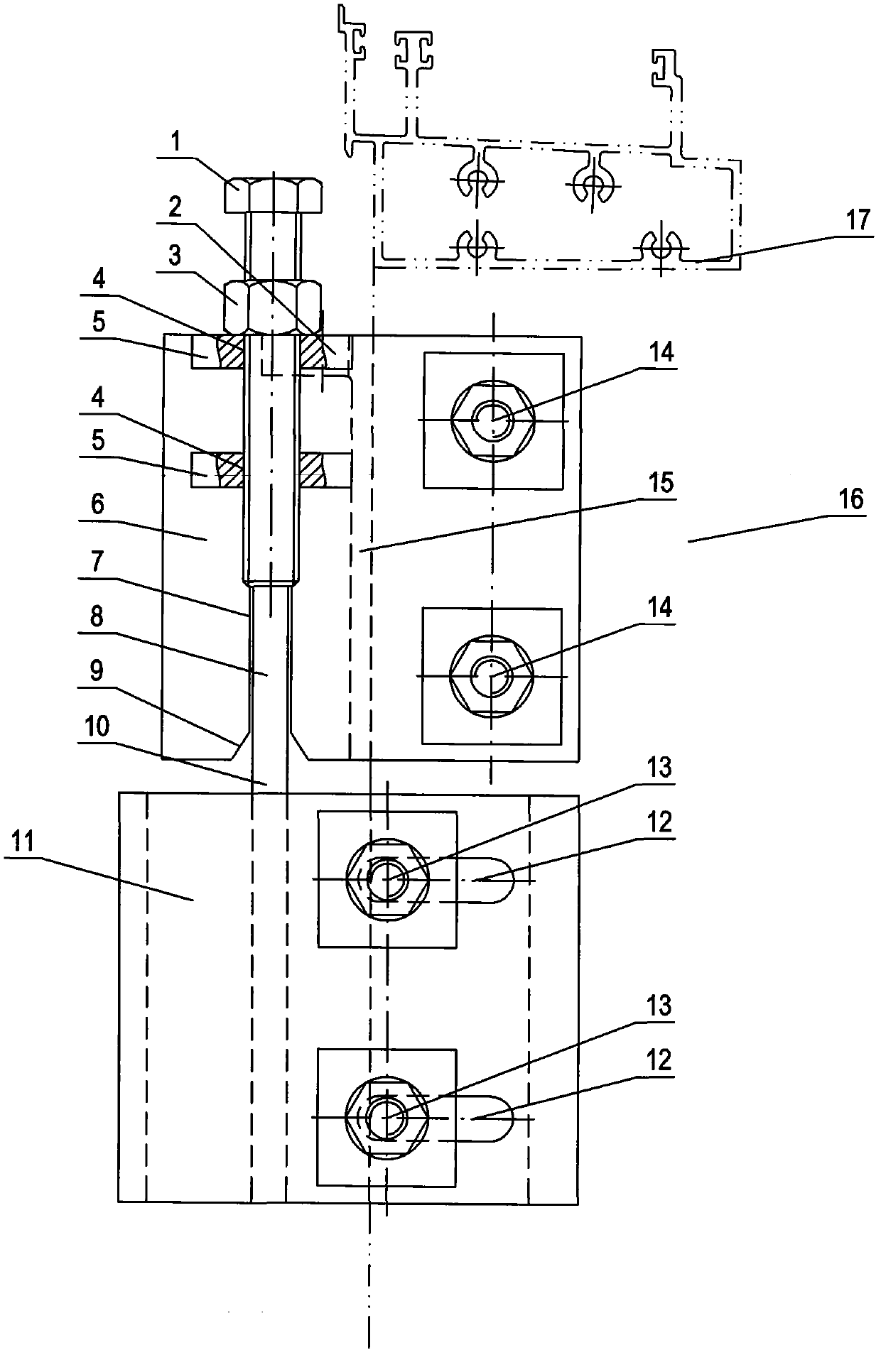

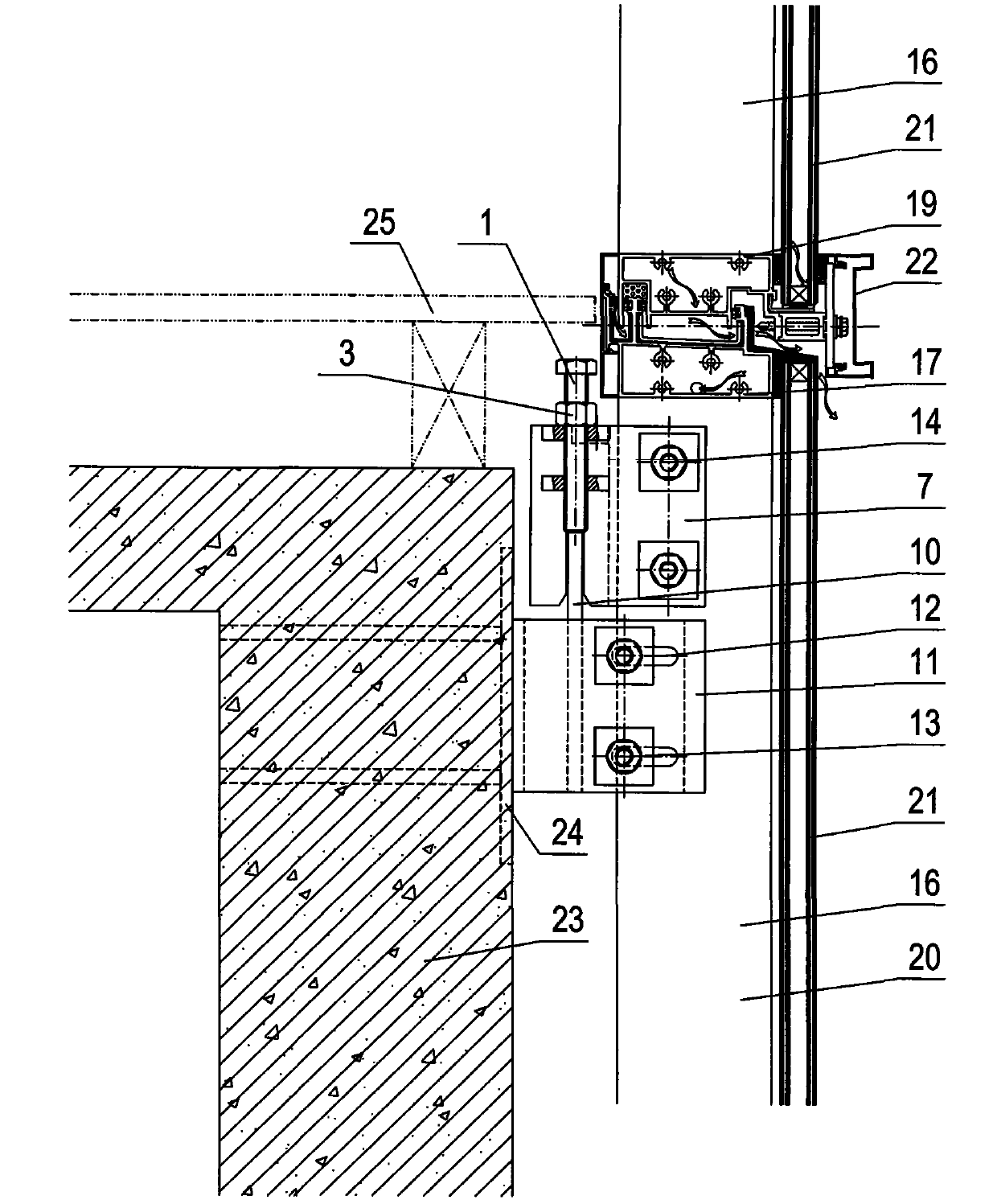

[0014] Such as Figure 1 ~ Figure 4 As shown, the vertical adjustment and load-bearing bolt 1, the lifting flange 2, the lock nut 3, the threaded hole 4, the vertical adjustment and load-bearing flange 5, the first corner code 6, the horizontal groove 7, the transverse flange 8, and the installation guide port 9. No. 2 corner code 10, No. 3 corner code 11, long waist round hole 12, connecting bolt 13, cylindrical head hexagon socket bolt 14, vertical cushion 15, unitized curtain wall stud 16, unitized curtain wall frame 17, lifting crane Hole 18, unitized curtain wall lower frame 19, unitized curtain wall plate 20, curtain wall glass 21, glass fixing and outdoor decoration parts 22 main structure 23, embedded parts 24, indoor floor 25, etc.

[0015] The present invention includes up and down adjustment and load-bearing bolt 1, first horn code 6, second horn code 10 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com