Novel composite graphitized deformed cathode for aluminium electrolysis

A technology of graphitization and aluminum electrolysis, which is applied in the field of aluminum electrolysis, can solve the problems of low production cost and leaky grooves, and achieve the effects of prolonging life, simple groove building, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

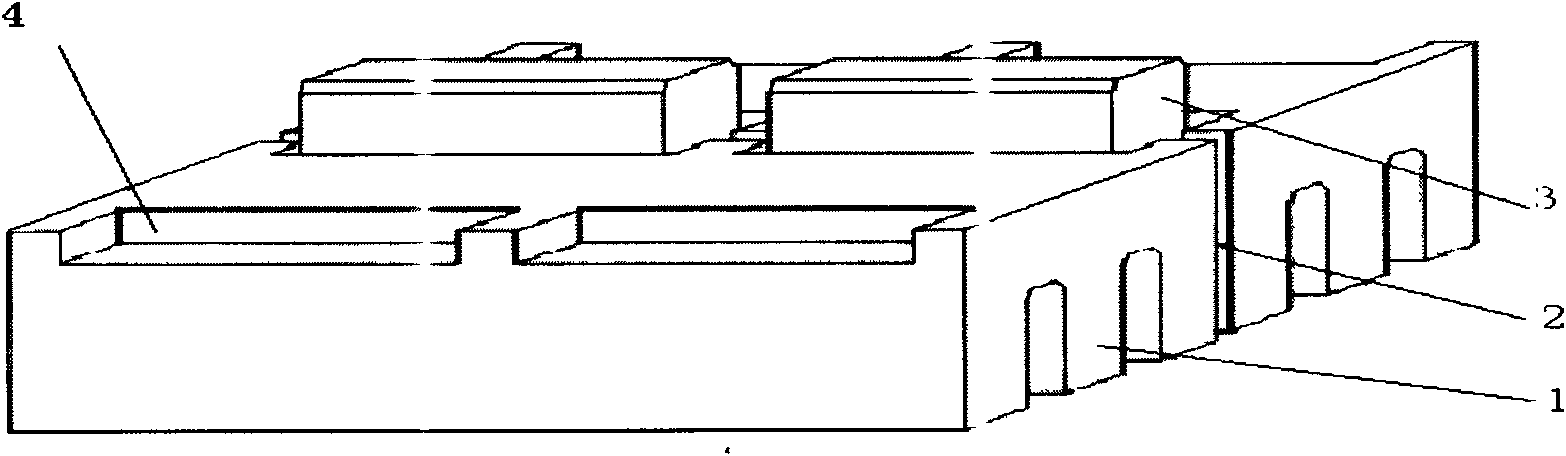

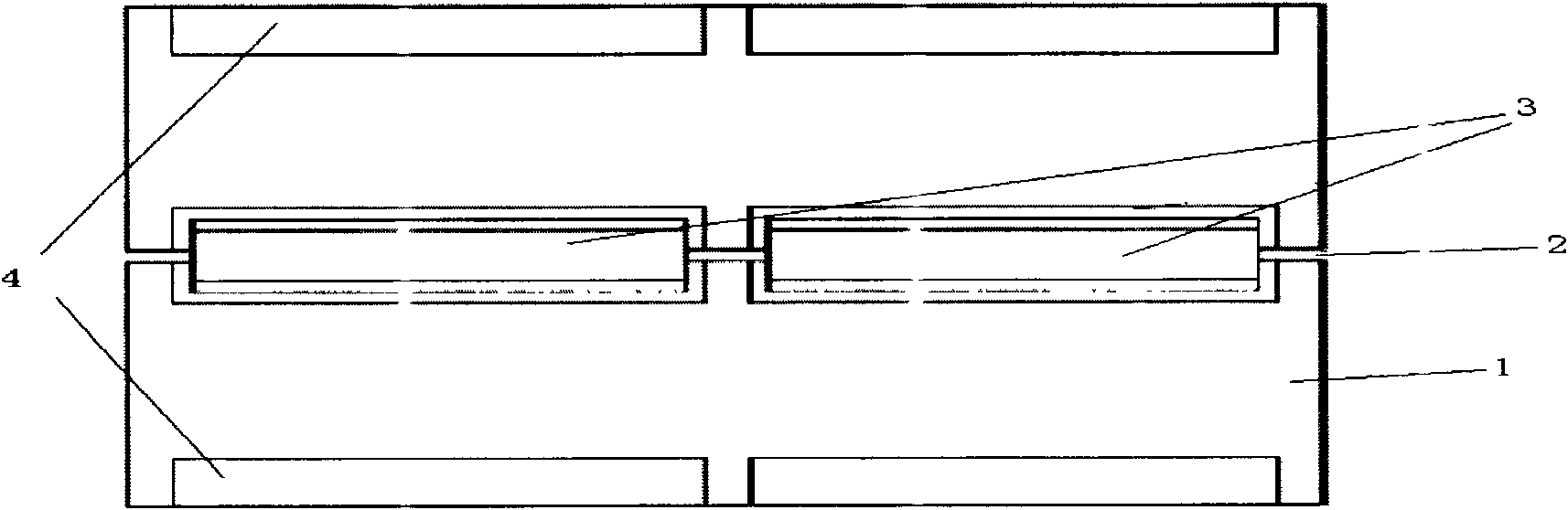

[0029] Such as figure 1As shown, the novel combined graphitized special-shaped cathode for aluminum electrolysis of the present invention, the external dimensions of the main body block and the length of the choke block are determined according to the size of the electrolytic cell and the installed capacity of the transformer; two sets of depths are arranged symmetrically on the longitudinal edge of the main body block (1). A groove (4) with a width of 100mm and a width of 80mm, the distance between the groove (4) and the laterally outer edge of the main body block is 300mm, and the distance between two grooves (4) on the same side is 300mm; it will be different from The graphitized cathode block (3) made of the material of the main body block, rectangular in cross section, 120 mm in height and 150 mm in width, spans the joint (2) of the two main body blocks (1), and is embedded in two grooves ( 4) Inside the combined groove; finally use the paste to tamp the joints (2) betwee...

Embodiment 2

[0031] Such as figure 1 As shown, one of the novel combined graphitized special-shaped cathodes for aluminum electrolysis of the present invention, the external dimensions of the main block and the length of the choke block are determined according to the size of the electrolytic cell and the installed capacity of the transformer; the longitudinal edges of the main block (1) are symmetrically opened There are two sets of grooves (4) with a depth of 125mm and a width of 90mm, the distance between the grooves (4) and the laterally outer edge of the main body block is 340mm, and the distance between two grooves (4) on the same side is 325mm ; Different from the material of the main body block, the cross-section is rectangular, the height is 190mm, and the graphitized cathode block (3) with a width of 175mm spans the connection seam (2) of the two main body blocks (1), and is embedded in the two In the groove formed by a combination of two grooves (4); finally use paste to tamp th...

Embodiment 3

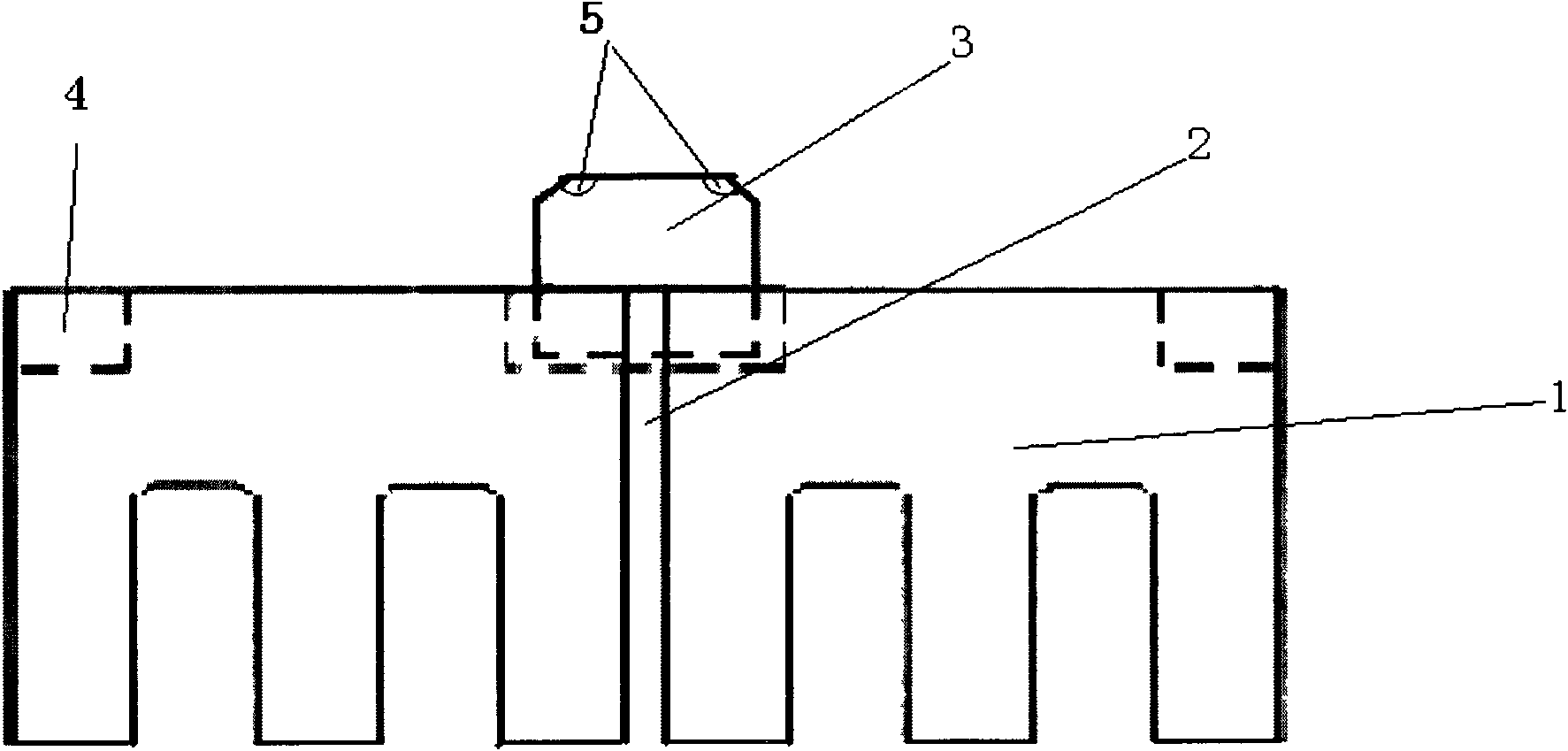

[0033] Such as figure 1 As shown, one of the novel combined graphitized special-shaped cathodes for aluminum electrolysis of the present invention, the external dimensions of the main block and the length of the choke block are determined according to the size of the electrolytic cell and the installed capacity of the transformer; the longitudinal edges of the main block (1) are symmetrically opened There are two sets of grooves (4) with a depth of 150mm and a width of 100mm, the distance between the grooves (4) and the laterally outer edge of the main body block is 380mm, and the distance between two grooves (4) on the same side is 350mm ; Different from the material of the main block, the cross section is convex, the overall height is 260mm, the overall width is 200mm, the angle of the top chamfer (5) is 135°, and the chamfer height is 30mm. (3) Across the connection seam (2) of the two main body blocks (1), inlaid in the groove formed by the two grooves (4); finally, paste ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com