Nano sulfur sol, and preparation method and application thereof

A sulfur sol and nanotechnology, applied in the field of nanomaterials, can solve the problems of instability, high cost, and less dissolved sulfur, and achieve the effects of convenient production and processing, low production cost, and convenient deep processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Take 0.02g of sublimated sulfur and add it to 20ml of polyethylene glycol 200, heat to 125°C, continue to reflux for 1h, and dissolve the sublimed sulfur in polyethylene glycol;

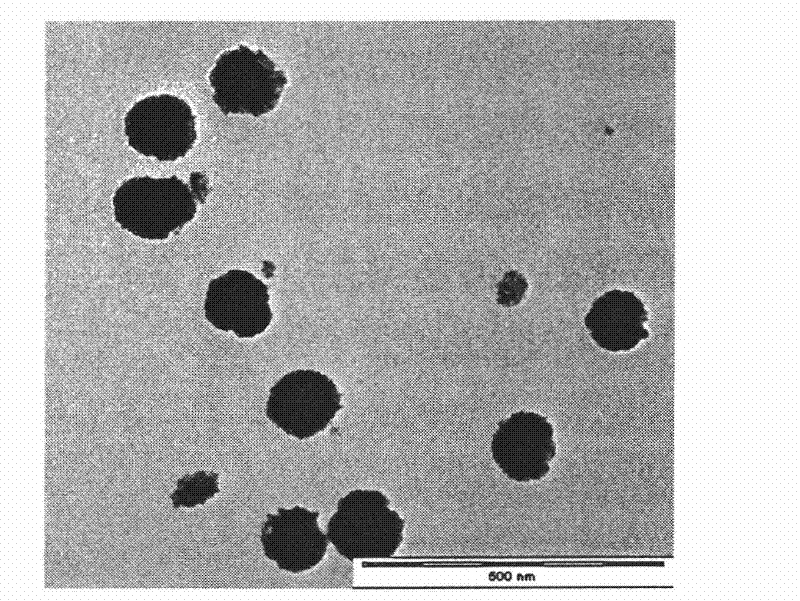

[0052](2) Transfer the reaction system of step (1) to ice water bath at 0°C for 10 minutes to obtain a light yellow nano-sulfur sol, which was left to stand at a constant temperature at 30°C. Get this sol in 30 days and carry out TEM (what adopted is the Philips TECNAI-10 type transmission electron microscope) observation, there is spherical nanometer sulfur (as in visible sol) in the sol Figure 1 ~ Figure 3 ).

Embodiment 2

[0054] (1) Add 0.4g of sublimated sulfur into 20ml of polyethylene glycol 200, heat to 115°C, continue to reflux for 1 hour, and dissolve the sublimed sulfur in polyethylene glycol;

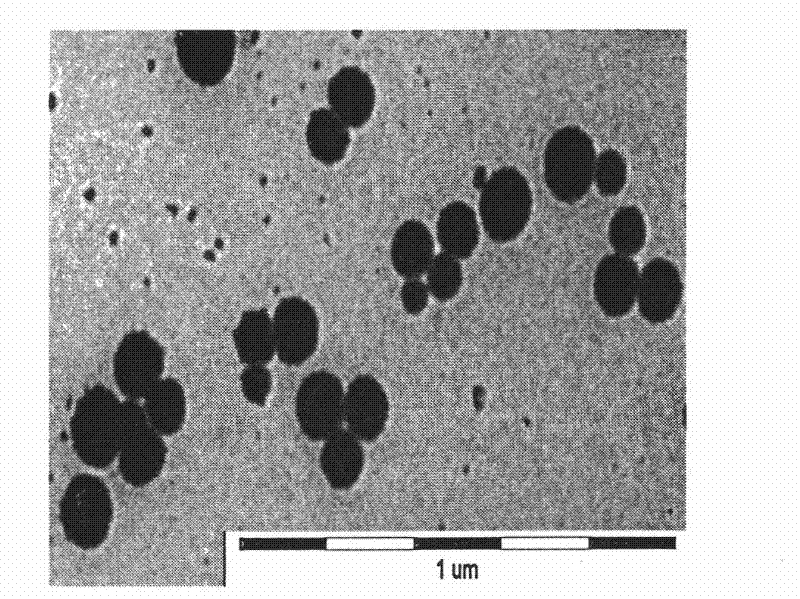

[0055] (2) Transfer the reaction system of step (1) to an ice water bath at 0°C, stir rapidly for 10 minutes, and then undergo high-speed centrifugation to separate and precipitate to obtain a light yellow nano-sulfur sol, which is left to stand at a constant temperature at 30°C, and respectively Get this sol on the 1st day, the 15th day, the 30th day and carry out TEM (what adopted is the Philips TECNAI-10 type transmission electron microscope) observation, visible sol has rod-shaped nanometer sulfur (such as Figure 4 ~ Figure 6 ).

Embodiment 3

[0057] (1) Take 0.02g of sublimated sulfur and add it to 20ml of polyethylene glycol 400, heat to 150°C, continue to reflux for 1h, and dissolve the sublimed sulfur in polyethylene glycol;

[0058] (2) Transfer the reaction system of step (1) to ice water at 0°C for 10 minutes to obtain a light yellow nano-sulfur sol, which was left to stand at a constant temperature at 50°C, and was treated on the 1st day, the 15th day, and the 1st day, respectively. Get this sol in 30 days and carry out TEM (what adopted is the Philips TECNAI-10 type transmission electron microscope) observation, there is spherical nanometer sulfur (as in visible sol) in the sol Figure 7 ~ Figure 9 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com