Full-automatic plastic detonating tube winding and bundling device

A detonating tube, fully automatic technology, applied in the field of fully automatic plastic detonating tube winding and beating device, can solve the problems of high labor intensity, waste of manpower and materials, and low work efficiency, so as to reduce labor intensity and improve work efficiency , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

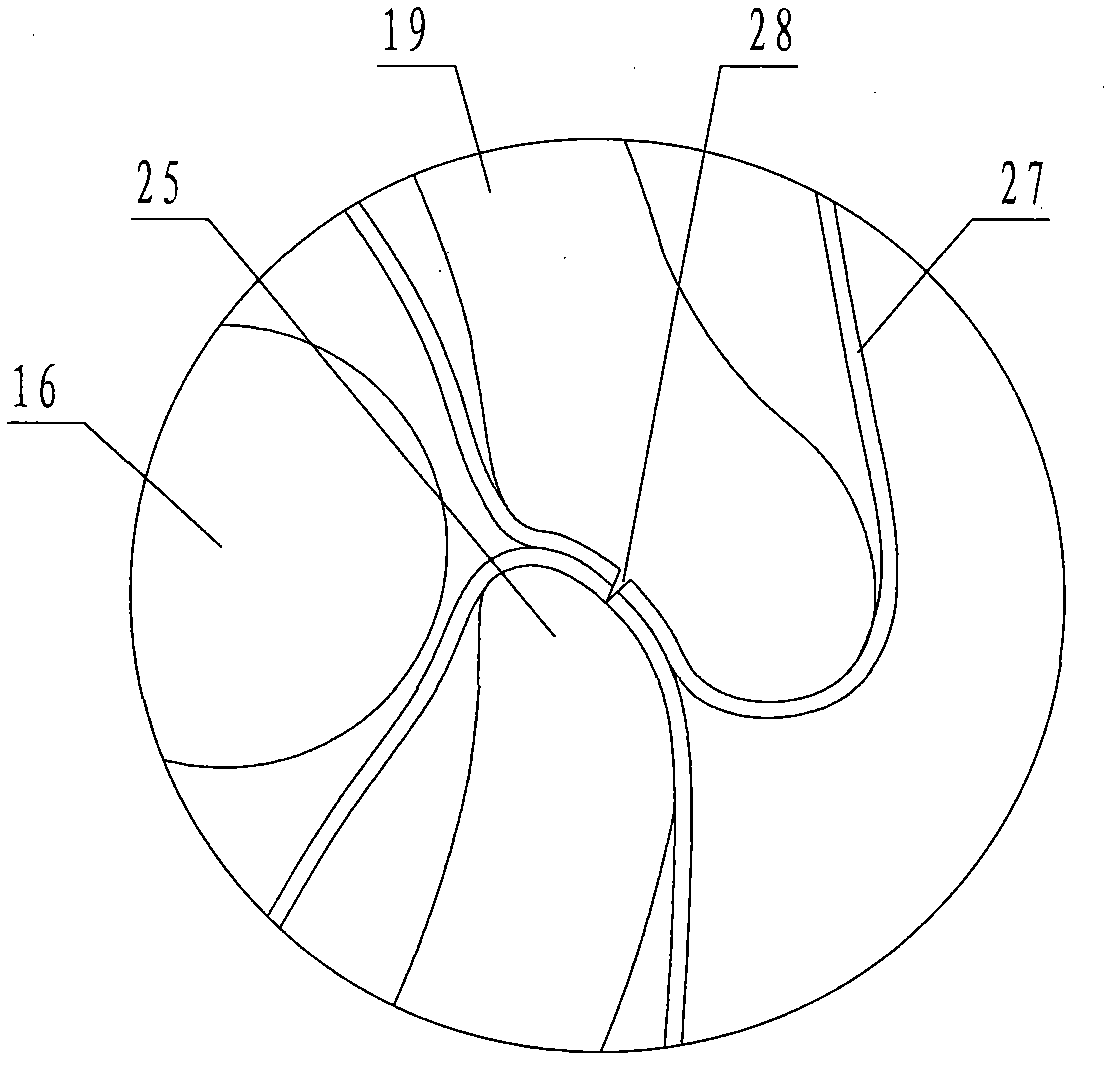

[0026] see figure 1 , the present invention mainly is made up of two major parts of beating mechanism and binding wire mechanism:

[0027] The handle mechanism is composed of a frame 10, a horizontal shaft 7, a turntable 15, a transmission disc 3, a transmission rod 6, an arched pallet 5, a pallet adjustment rod 2, an unloading cylinder 11 and a drive motor 13. The horizontal shaft 7 passes through the bearing It is connected with the frame 10, and one end thereof is connected with the driving motor 13 through the reduction box 12, and the electromagnetic brake 14 is installed on the driving motor 13. The other end of the horizontal rotating shaft 7 is fixed with the transmission disc 3, the transmission disc 3 drives the turntable 15 to rotate through the transmission rod 6, the turntable 15 and the horizontal rotating shaft 7 are connected by bearings, and a plurality of positioning shafts 1 are passed on one side edge of the turntable 15. A plurality of arched supporting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com