Steam turbine blade fitting measuring tool and processing technology thereof

A steam turbine blade and blade assembly technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of delayed unit manufacturing cycle, heavy repair workload, low work efficiency, etc., to avoid batch quality problems of blades, improve The effect of assembly work efficiency and shortened manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

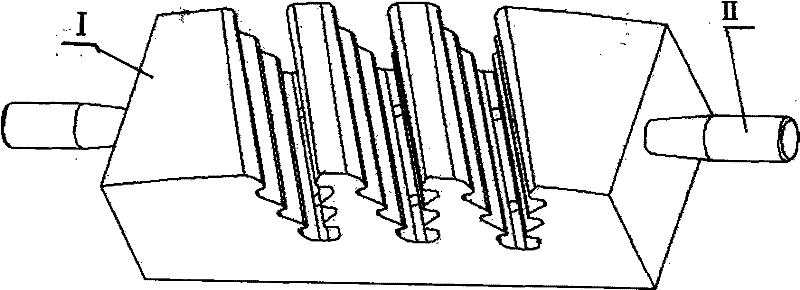

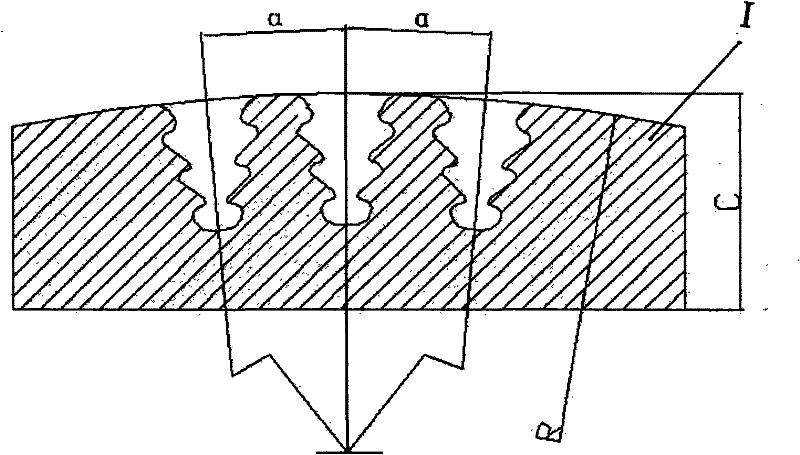

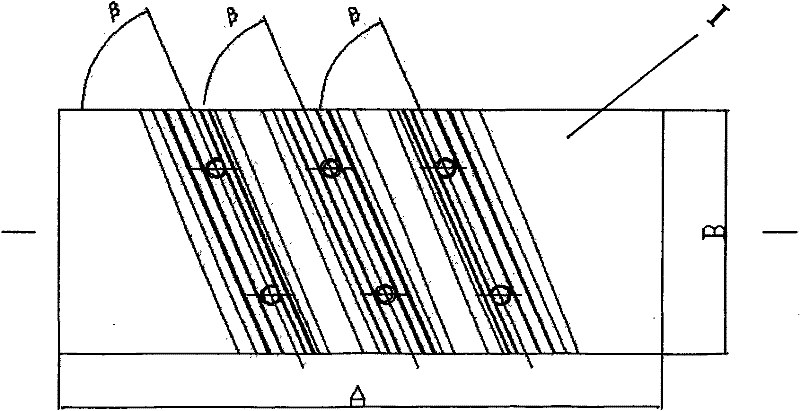

[0031] When designing the whisk distribution measuring tool, it simulates an arc segment of the impeller, which is called a false impeller. Generally, three blades are considered to be installed, that is, there are three blade assembly grooves on the whisk distribution measuring tool, and the contour line, radial radius and circumference of the assembly groove The graduations in the direction are designed according to the profile line, radial radius and circumferential graduation of the rotor blade assembly groove respectively.

[0032] Considering the convenience of processing and use, the shape of the false impeller is not necessarily designed to be strictly fan-shaped, the inner arc surface is changed to a horizontal plane, and the two circumferential sides are not sloped, but are changed to vertical surfaces. In addition, in order to facilitate the movement during use, a pair of handles are designed on the false impeller, which are arranged on the two circumferential sides....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com