Micro-torque sensor calibrator based on magnetic suspension effect

A micro-torque and sensor technology, applied in force/torque/power measuring instrument calibration/testing, instruments, measuring devices, etc., can solve problems such as difficult to meet the calibration requirements of micro-torque sensors, and achieve elimination of adverse effects and good stability , high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with drawings and embodiments.

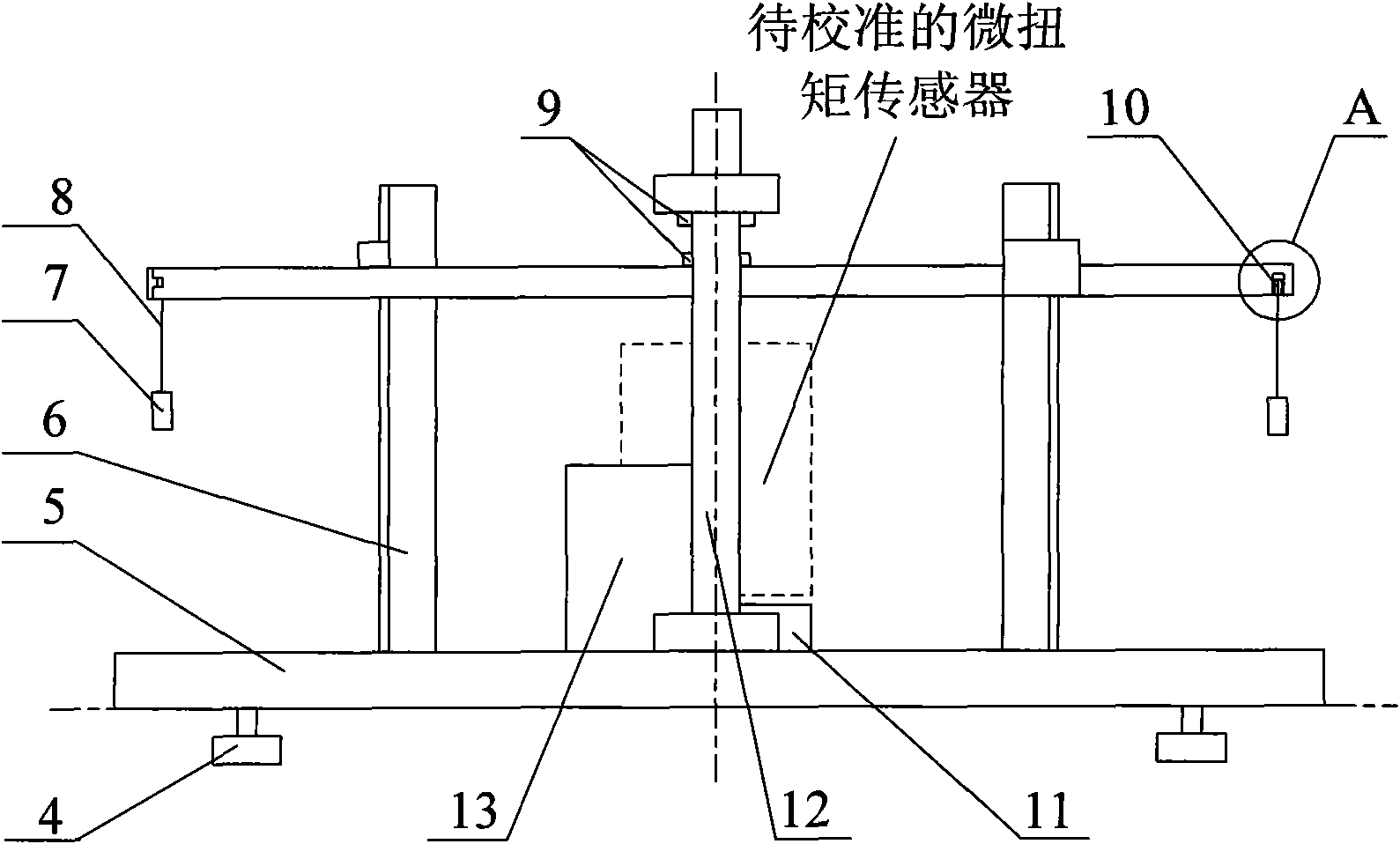

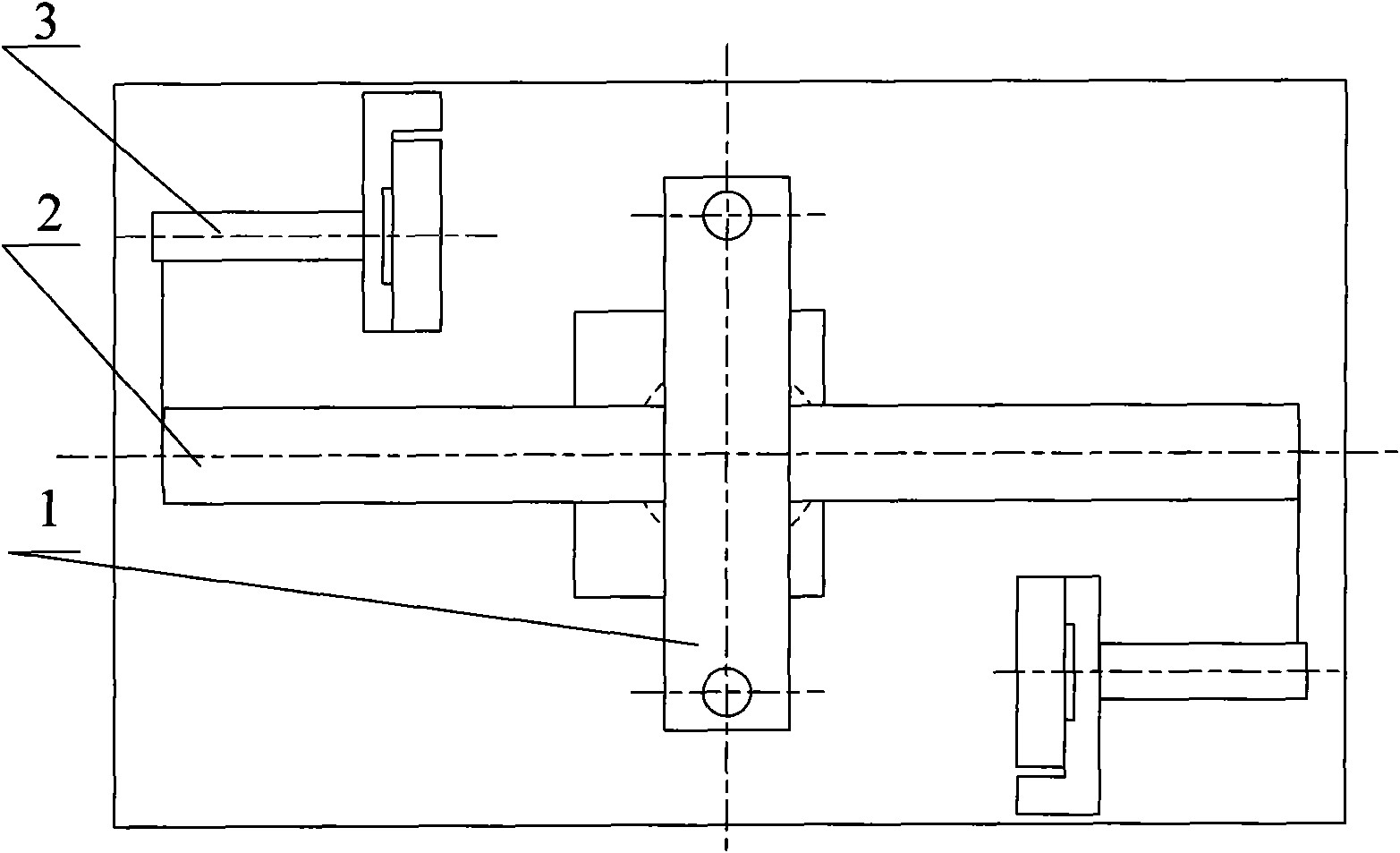

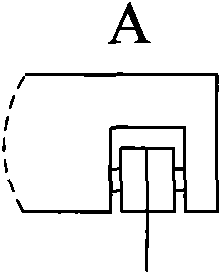

[0011] Such as figure 1 , figure 2 and image 3 As shown, the present invention includes a magnetic base 1, a force arm 2, a bearing frame 3, a height-adjusting support foot 4, a base 5, a guide rail 6, a weight 7, a lead wire 8, a disc-shaped magnet, a micro-bearing 10, and a holding block 11 , guide post 12, these elements of positioning block 13. The micro-torque sensor to be calibrated is placed vertically, fixed on the base 5 by the positioning block 13 and the tight block 11, and the rotating shaft is equipped with the arm 2 of the arc edge; the first guide rail 6 and the second guide rail 6 are fixed on the base 5; The first bearing frame 3 is installed on the first guide rail 6, the first bearing frame 3 can move up and down along the first guide rail 6 and slotted at the end, the first micro bearing 10 is housed in the groove; the first lead wire 8 passes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com