Roof with rectangular plane, super-long span and prestressed space tube truss structure and manufacturing method

A tube truss, rectangular technology, applied in the field of super-span prestressed steel structure roof, to achieve the effect of low space height, length reduction, and steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

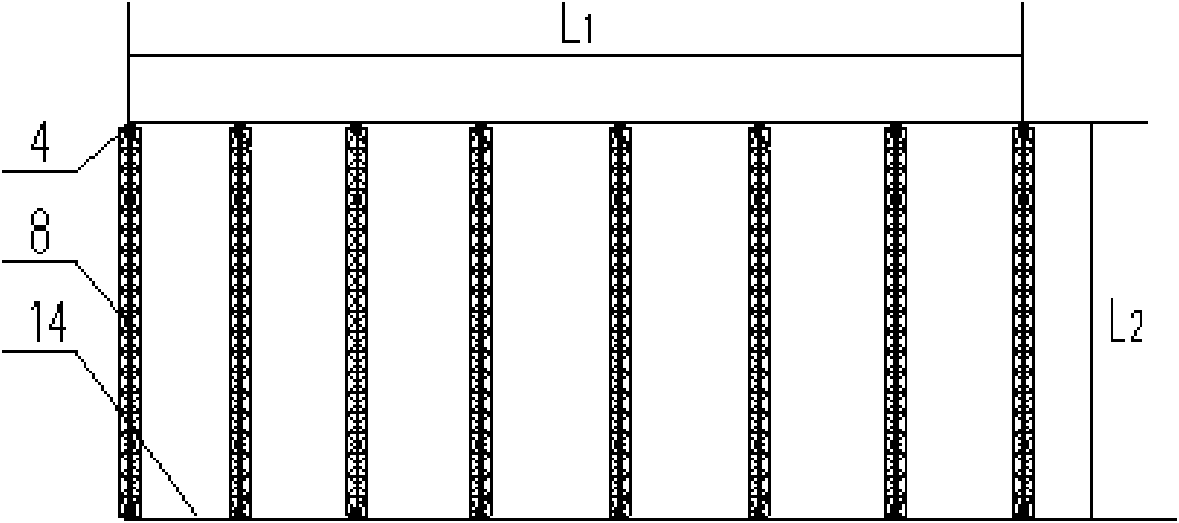

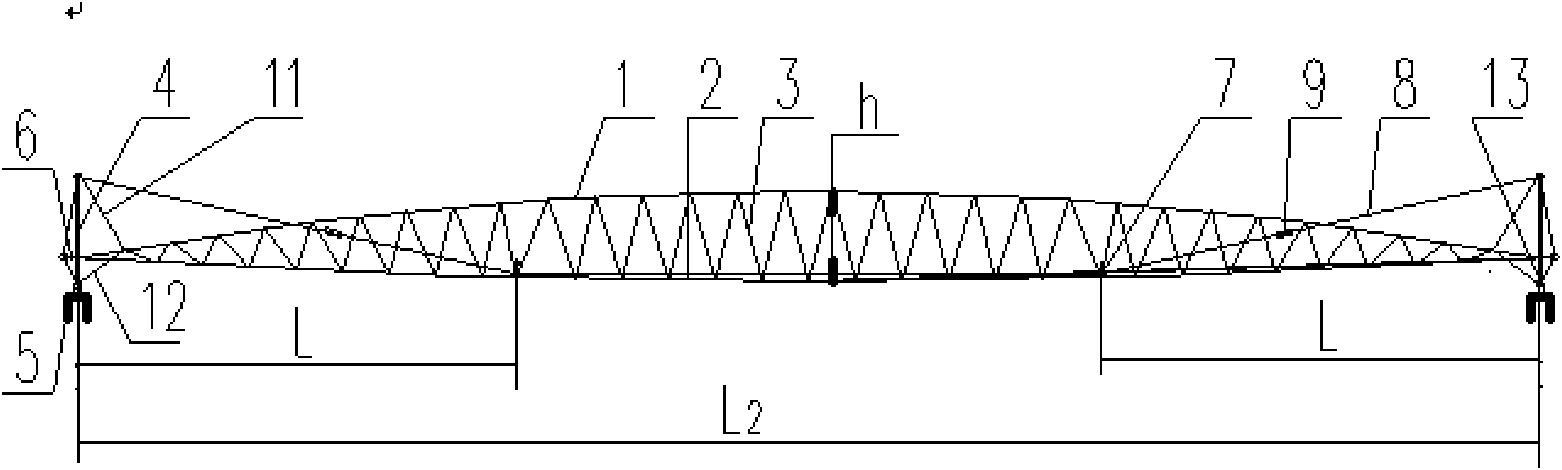

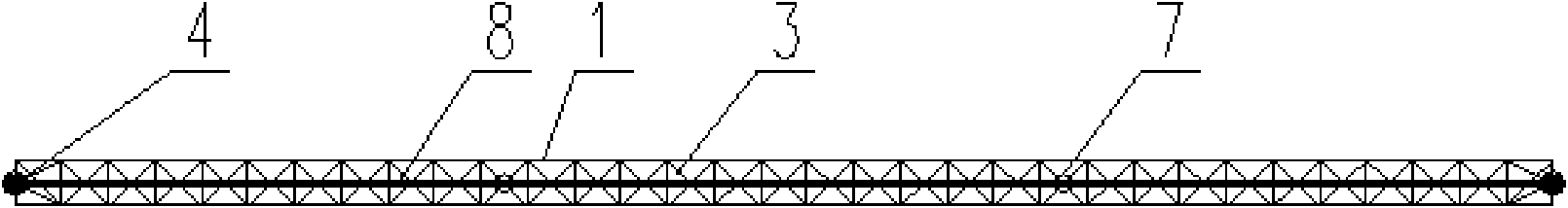

[0025] Embodiment of the present invention: make roof plane be the rectangle plane of rectangle and its long side L 1 with short side L 2 The ratio is L 1 / L 2 ≥1.5 and L 2 is the span of the roof and is 90 meters ≤ L 2 When the roof is less than or equal to 150 meters, a rectangular plane super-large-span prestressed space tube truss roof manufacturing method of the present invention is used to make it, that is, the super-large-span support strut type cable-stayed self-balancing space tube truss is used as the roof. The super-large-span support rod-type cable-stayed self-balancing space tube truss is based on the structure of the conventional shuttle-shaped space tube truss, and is set on the supports at both ends of each shuttle-shaped space tube truss. Based on the support rods supporting the steel cables, the structural height h in the center of the shuttle-shaped space tube truss is made as L 2 / 18≤h≤L 2 / 16, and (1 / 4~1 / 3)L from the center line of the support at bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com