Method for detecting operation troubles of mine hoist

A technology of mine hoist and operation failure, applied in the direction of hoisting equipment, elevator, transportation and packaging in the mine, can solve the problem of inability to detect the hoist, and achieve the effect of wide practicability, simple hardware equipment and strong real-time performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

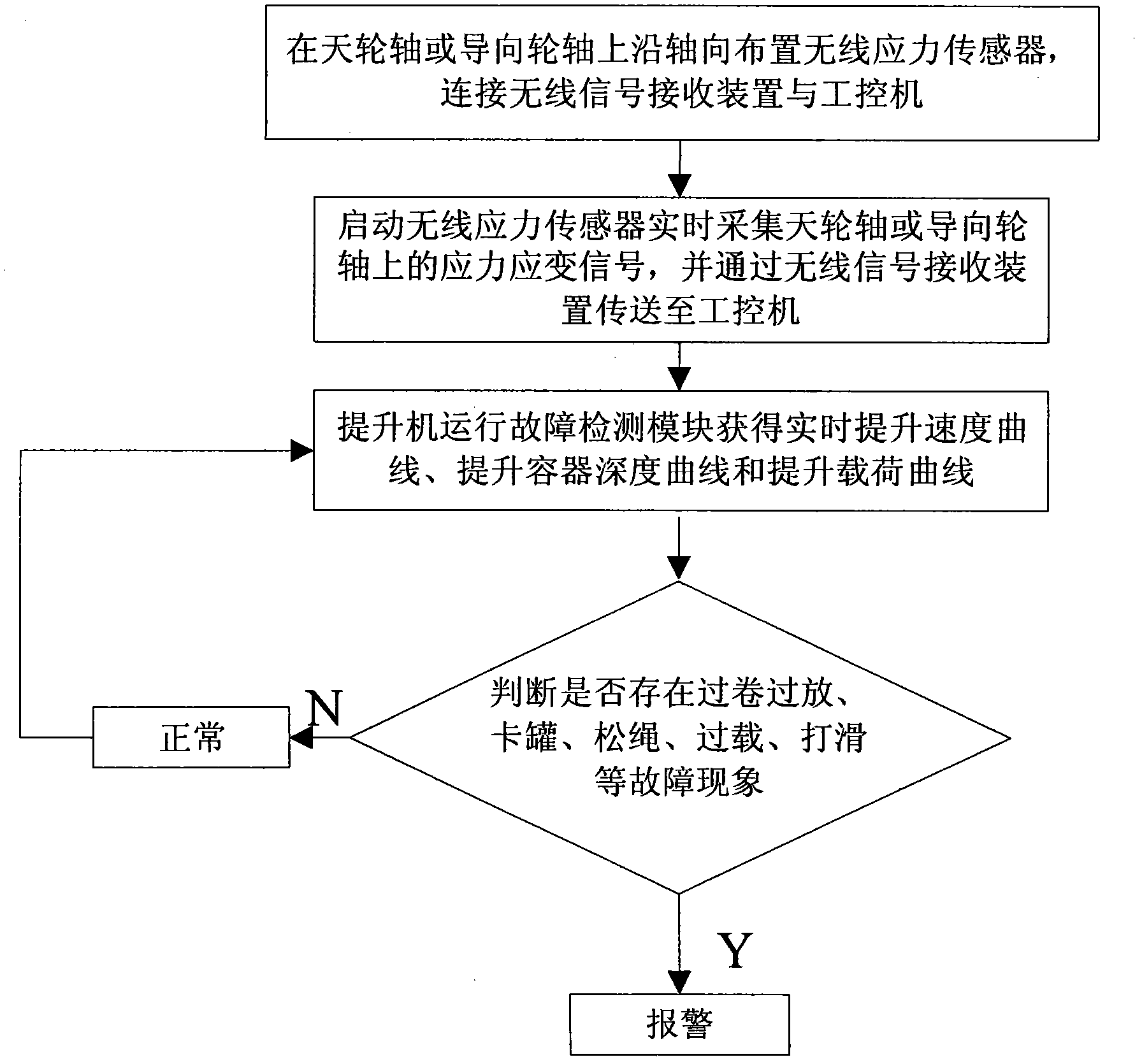

[0033] Embodiment 1: implement the hoist operation failure detection method of the present invention according to the following steps on the mine friction hoist:

[0034] Step 1. Arrange a wireless stress sensor axially on the guide wheel shaft of the friction hoist, using a DH5905 wireless stress sensor; arrange a wireless signal receiving device near the guide wheel, using a DH5905 wireless signal receiver; the wireless signal receiving device is connected through a USB interface Connected with industrial computer;

[0035] Step 2, start the wireless stress sensor, the wireless stress sensor collects stress and strain signals from the guide wheel shaft in real time, and sends the collected stress and strain signals to the wireless signal receiving device, and the wireless signal receiving device transmits the stress and strain signals to the industrial computer;

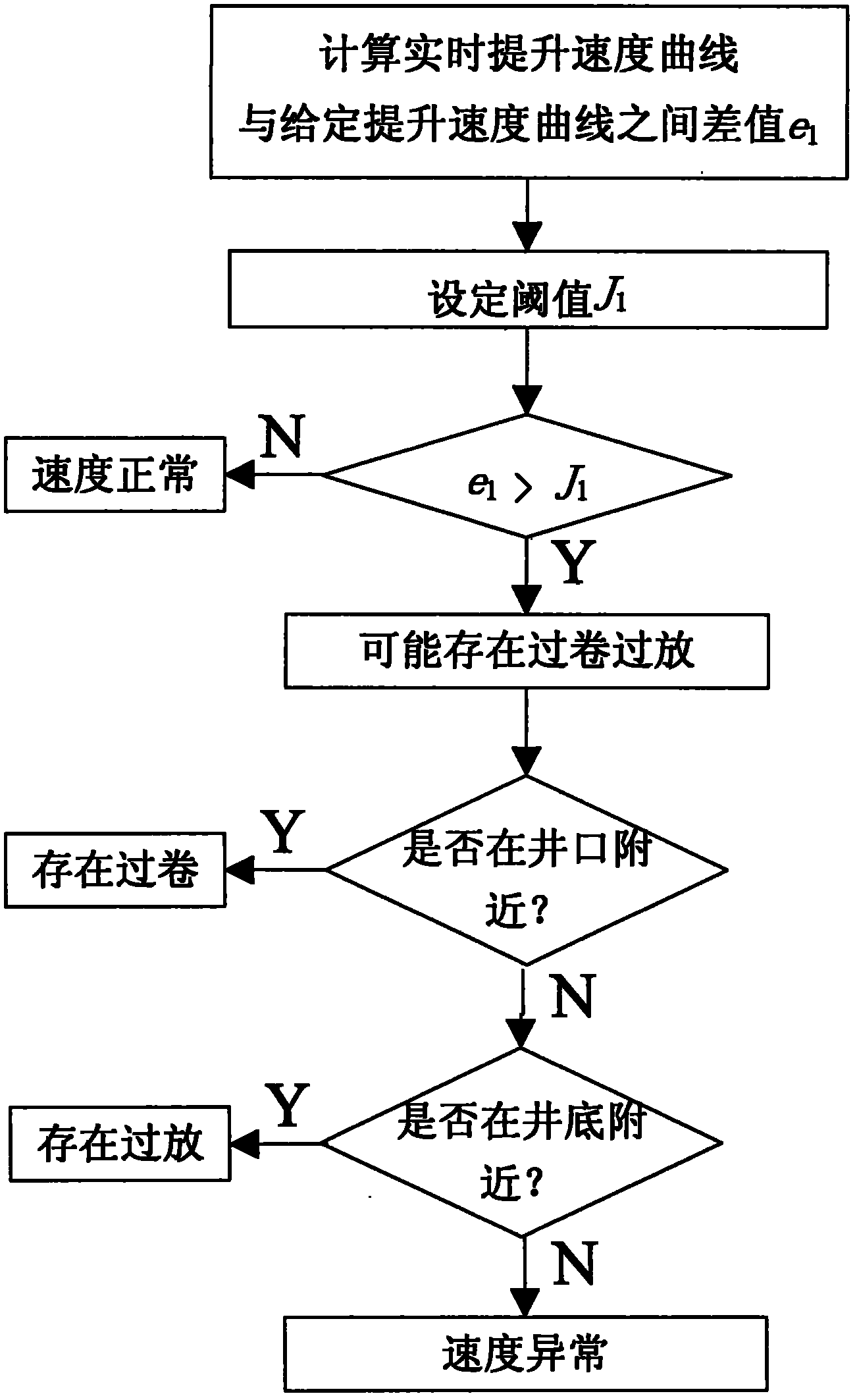

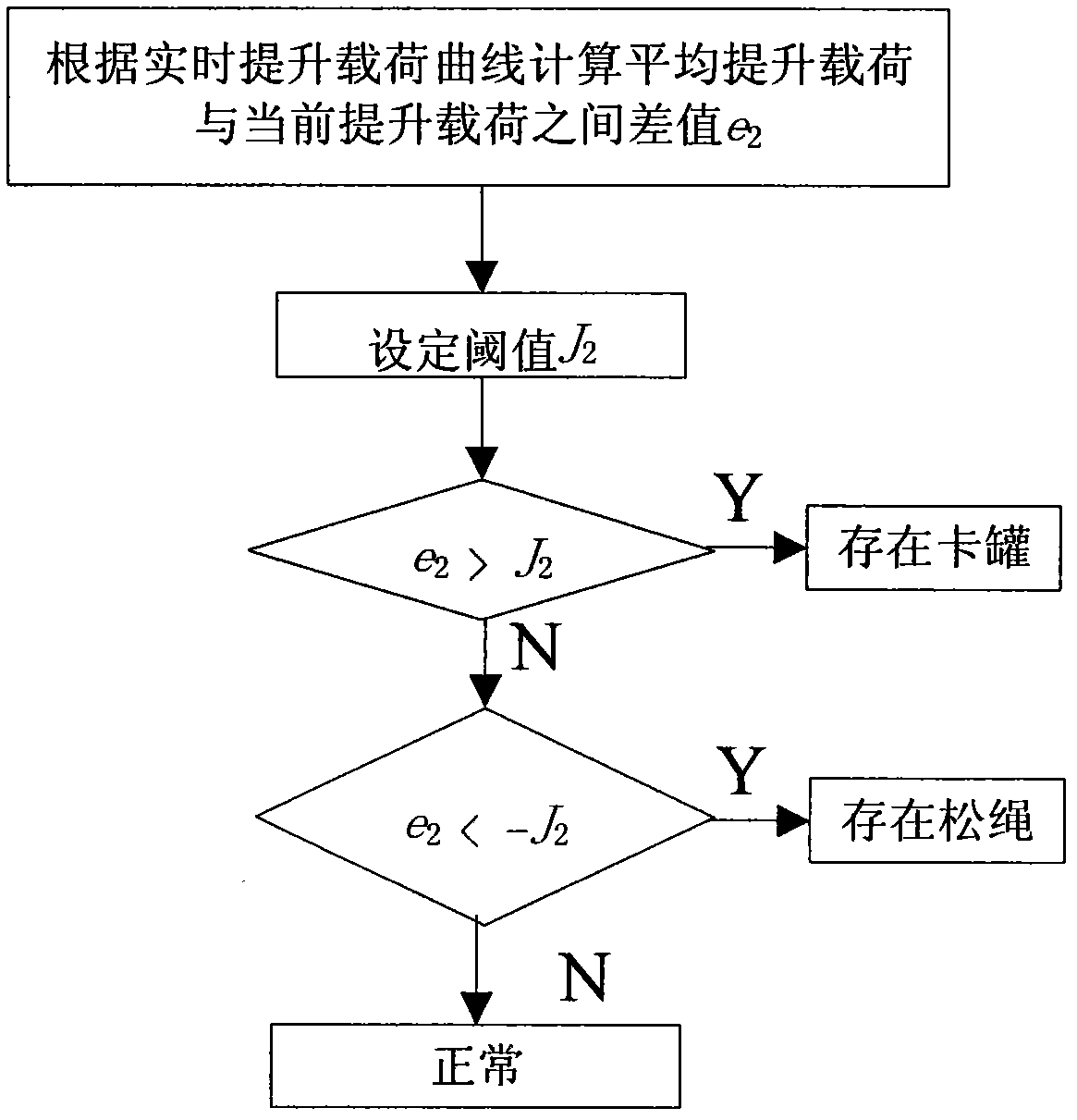

[0036] Step 3. The hoist fault detection module in the industrial computer obtains the real-time hoisting speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com