Multi-station friction screw press

A screw press, multi-station technology, applied in the field of presses, can solve problems such as screw failure and inability to use multi-station forging, and achieve the effects of improving screw life, compact spacing and reducing eccentric load moment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

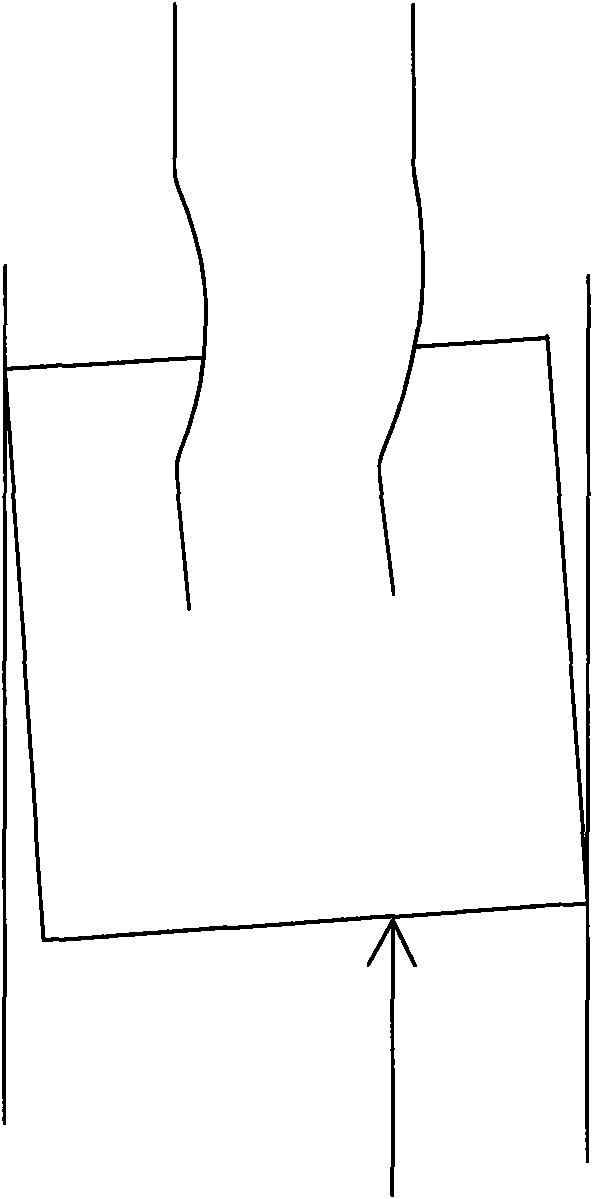

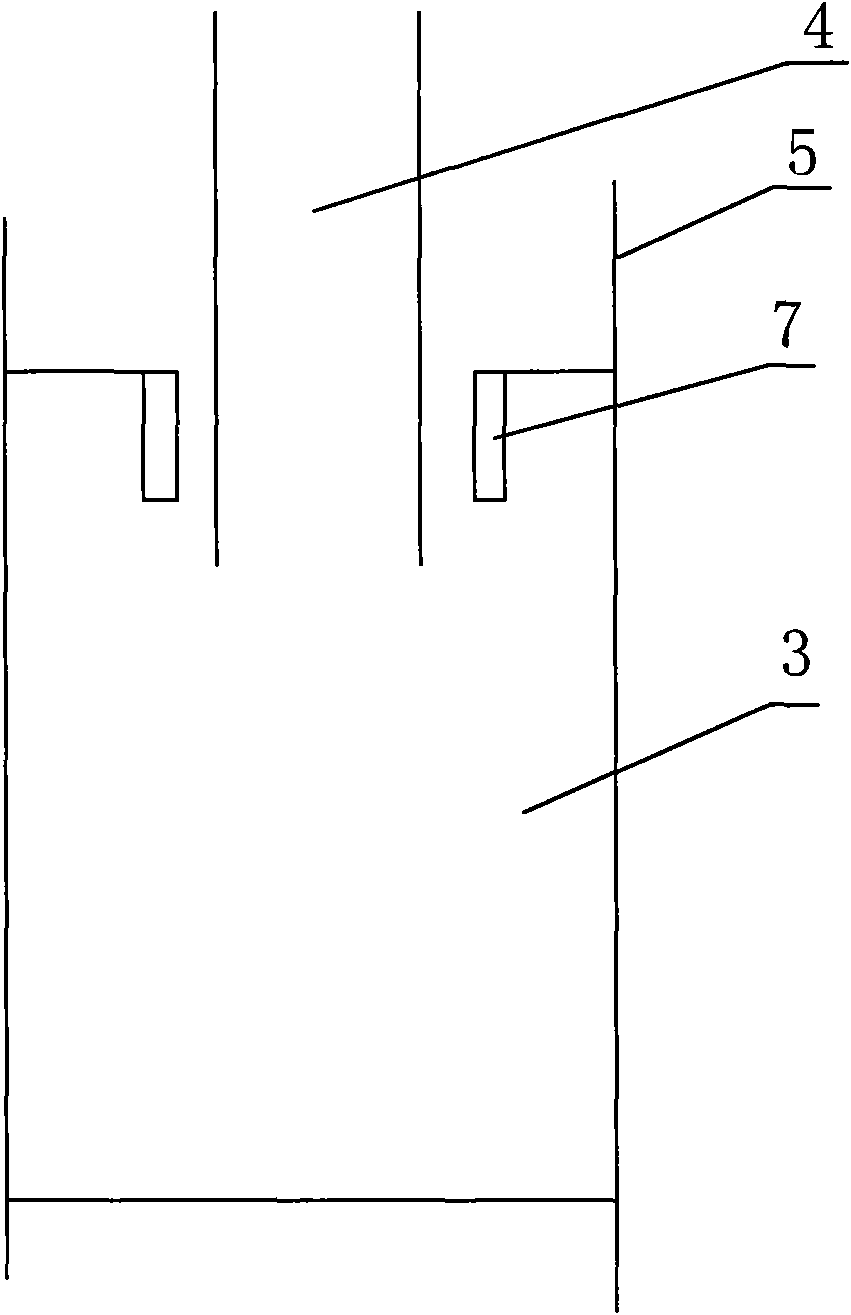

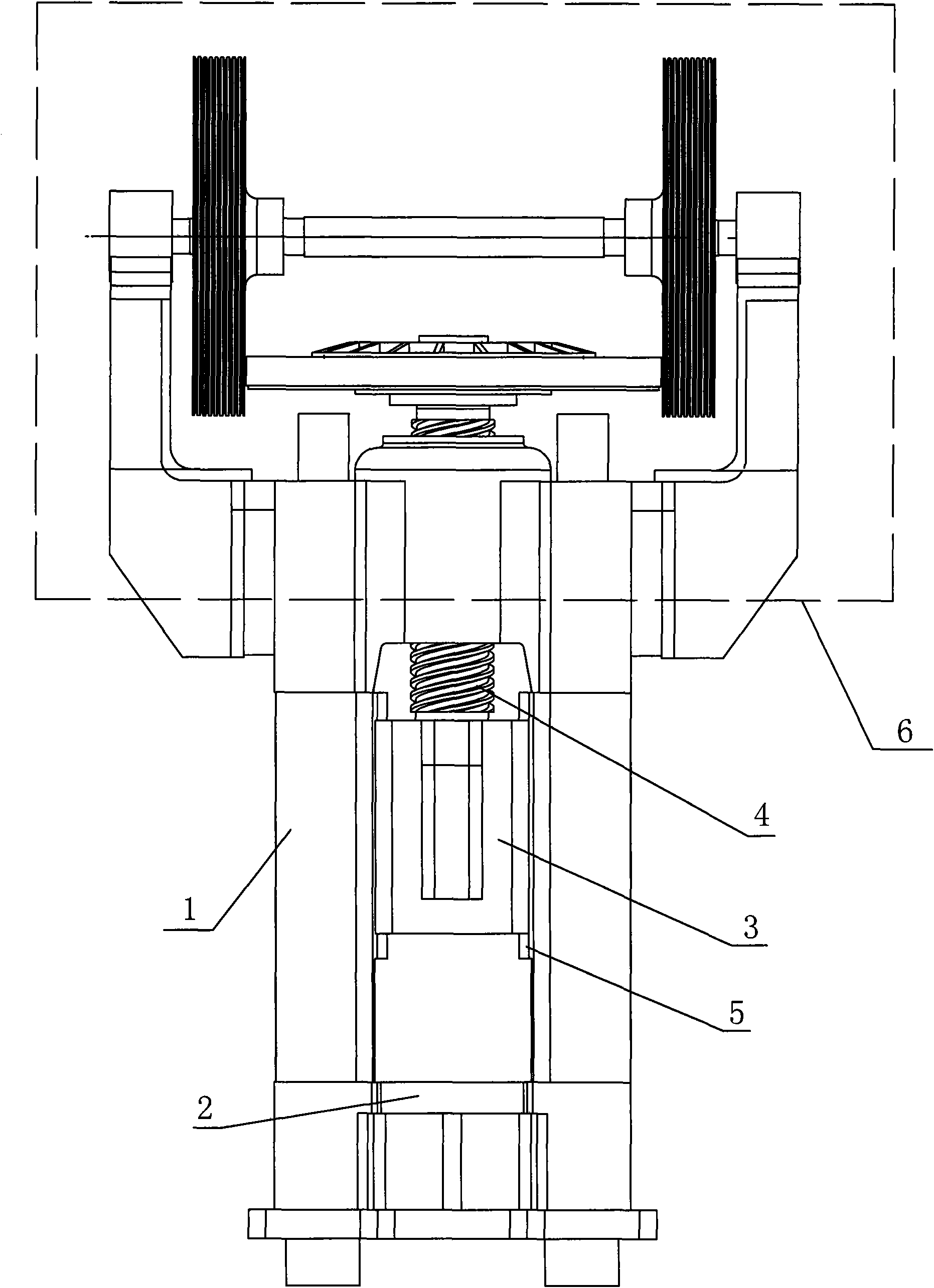

[0024] Such as Figure 2-4 As shown, a multi-station friction screw press in this embodiment includes a fuselage 1; a multi-station mold 2 arranged on the workbench of the fuselage 1; The slider 3 above; one end is inserted in the slider 3, rotatably connected with the slider 3, and the screw 4 that drives the slider 3 to move up and down is arranged on the fuselage 1, and is connected to the slider 3. A plurality of guide rails 5 for guiding the slider 3, and the distance between the guide rails 5 is suitable for the slider 3 to slide between the guide rails 5; it is connected with the other end of the screw rod 4 and can drive The screw driving device 6 that rises or falls while the screw 4 is forward or reverse; The centers are close together, which makes the distance between each station more compact, thereby reducing the unbalanced load moment and reducing the damage to the press. It solves the problem that in the traditional multi-station forging, separate installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com