Method for processing back of business suit of men

A processing method and back technology, applied in clothing, apparel, application and other directions, can solve the problems of the back seam arc of the garment, not close to the body, and the appearance is not beautiful, so as to achieve the effect of wearing comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

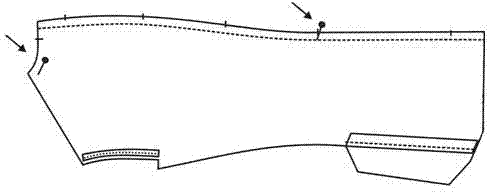

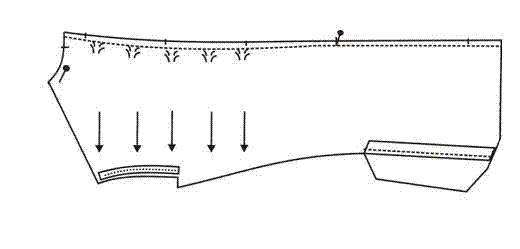

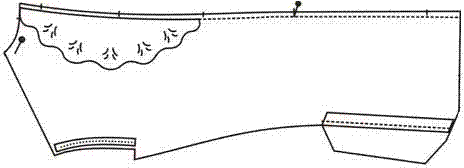

[0040] In step 3), pull the back piece 0.8CM flat from the armhole, and iron the back center seam; in step 4), continue to pull the back piece 2CM (see figure 2 ), and then iron the amount of the rear middle seam. The ironing is divided into two times because the amount of ironing is large, and the effect cannot be achieved in one operation, so it is completed in two times; in step 6), the looseness of the outer arc of the lining is 0.8CM; in step 9), stick a 2.5CM lining strip on the middle lining, the lining strip passes through the suture 0.2CM, and the lower end passes the middle lining 2CM.

Embodiment 2

[0042] In step 3), pull the back piece 1CM flat from the armhole, and iron the back seam; in step 4), continue to pull the back piece 1.5CM (see figure 2 ), and then iron the amount of the rear middle seam. The ironing is divided into two times because the amount of ironing is large, and the effect cannot be achieved in one operation, so it is completed in two times; in step 6), the looseness of the outer arc of the lining is 0.5CM; in step 9), stick a 2.5CM lining strip on the middle lining, the lining strip passes through the suture 0.5CM, and the lower end passes the middle lining 3CM.

[0043] Process standard:

[0044] The amount of ironing is uniform, the position is accurate, the ironing part is flat, the lining position is accurate, the lining strip is used accurately, and the lining part is smooth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com