Knife switch overhaul platform

A technology for repairing platforms and knife gates. It is applied in the direction of lifting devices, lifting frames, and switchgears. It can solve problems such as broken porcelain columns, increased personnel falling from high places on porcelain columns, and endangering personal safety. It achieves short installation time and avoids high-altitude problems. Effects of falling and improving work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific drawings and embodiments.

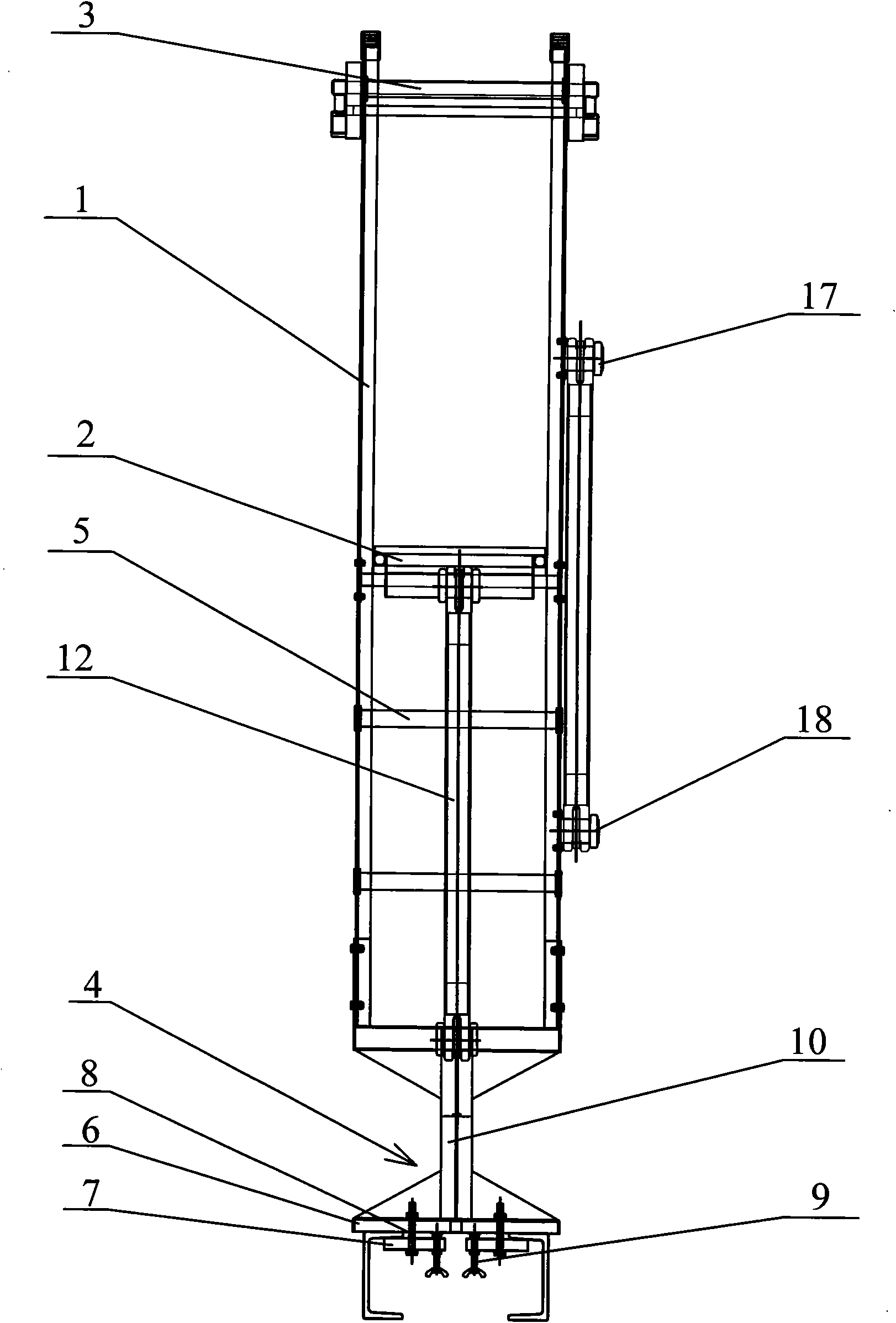

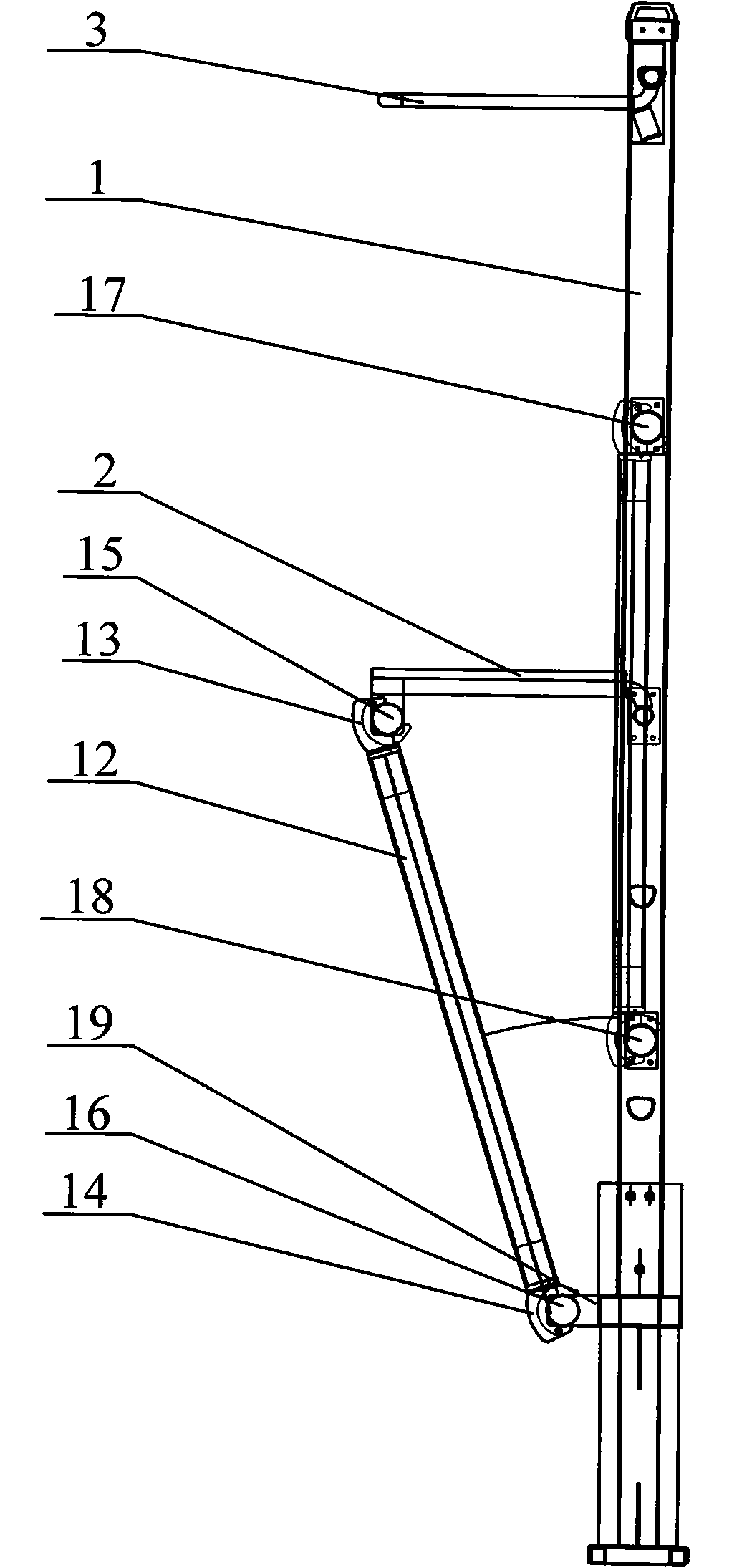

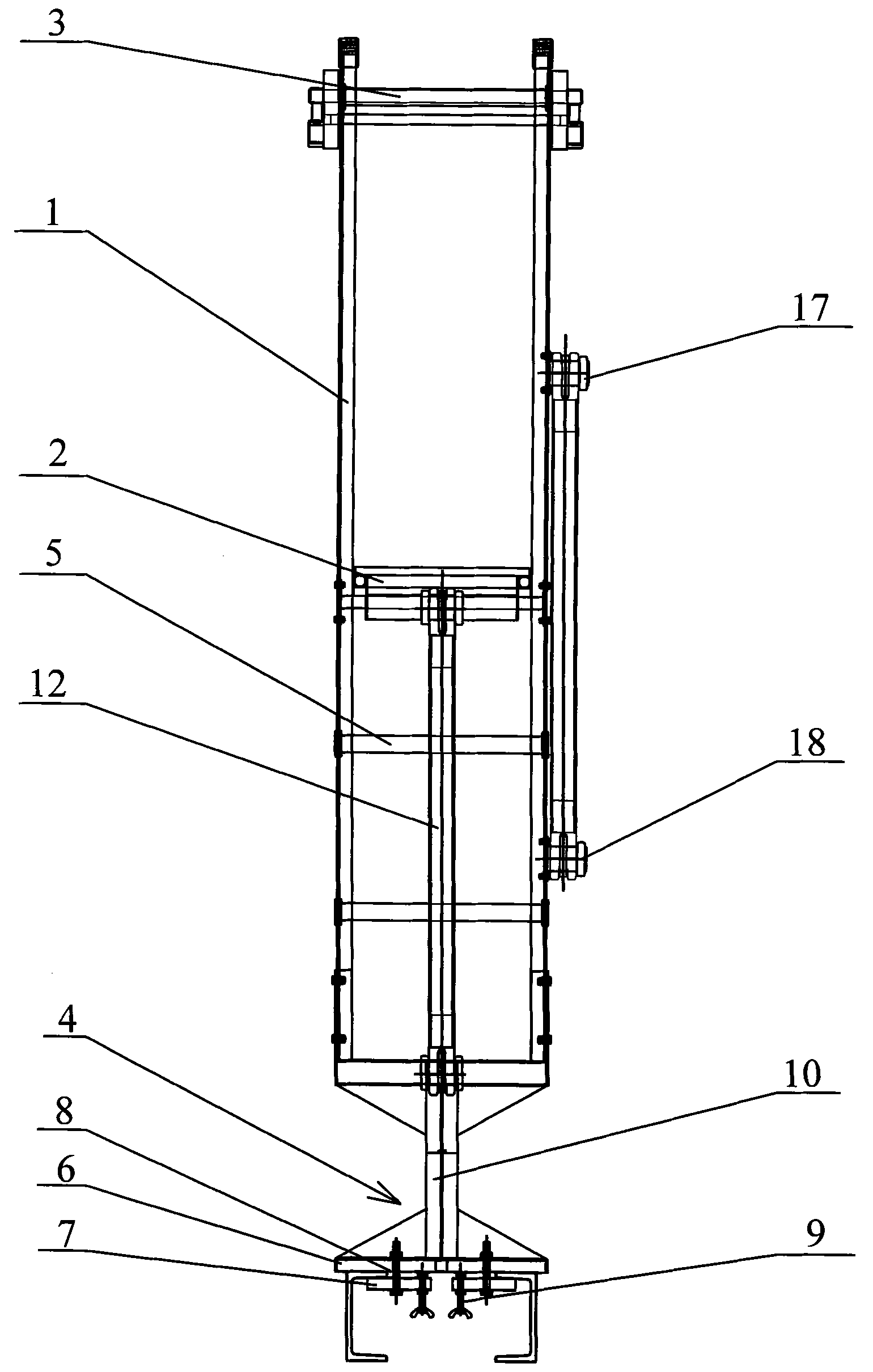

[0014] As shown in the figure: the knife gate maintenance platform includes a standing platform 2 installed in the middle of the stand 1, and a connecting base 4 is provided at the bottom of the stand 1.

[0015] The stand 1 below the standing platform 2 is provided with several ladder plates 5 arranged in parallel. It is convenient for the operator to board the standing platform 2 .

[0016] The connecting base 4 includes a bottom plate 6, a splint 7, locking bolts 8 and jacking bolts 9, the splint 7 is installed under the bottom plate 6 through the locking bolts 8 and the jacking bolts 9, and the middle part of the connecting base 4 is fixedly installed with The connecting column 10, the top end of the connecting column 10 is fixedly connected with the bottom end of the stand 1, and the two sides of the connecting column 10 are provided with independent spli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com