Single-screw rod engine and energy converting method thereof

A technology of energy conversion and engine, which is applied in the direction of combustion engine, machine/engine, internal combustion piston engine, etc., and can solve problems such as crankshaft impact, low efficiency, and unstable operation of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

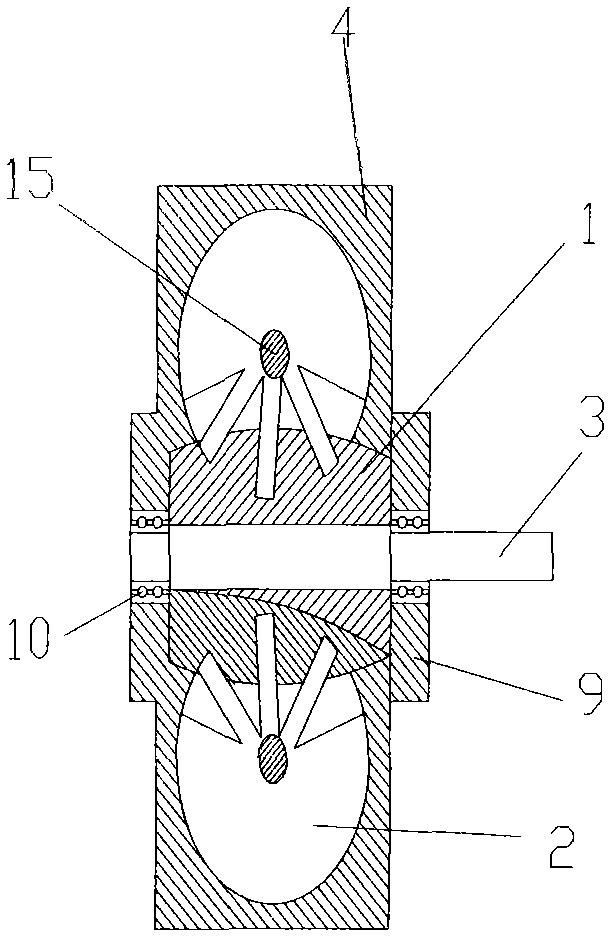

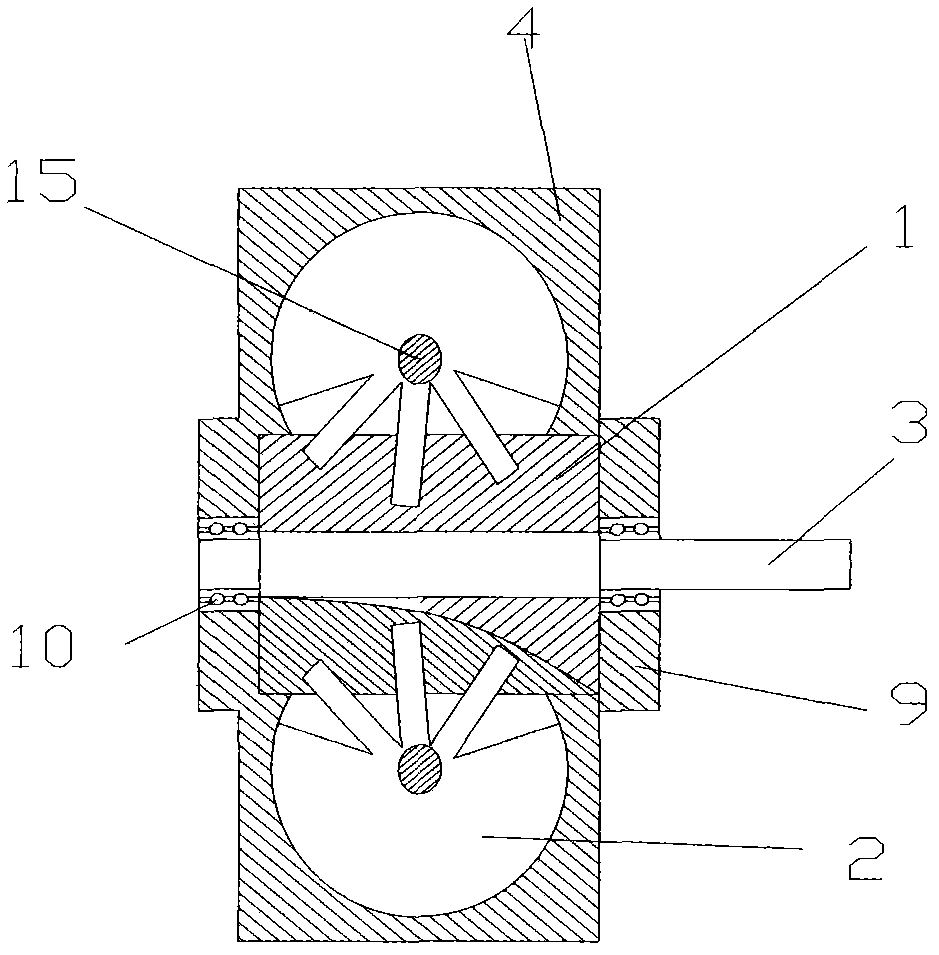

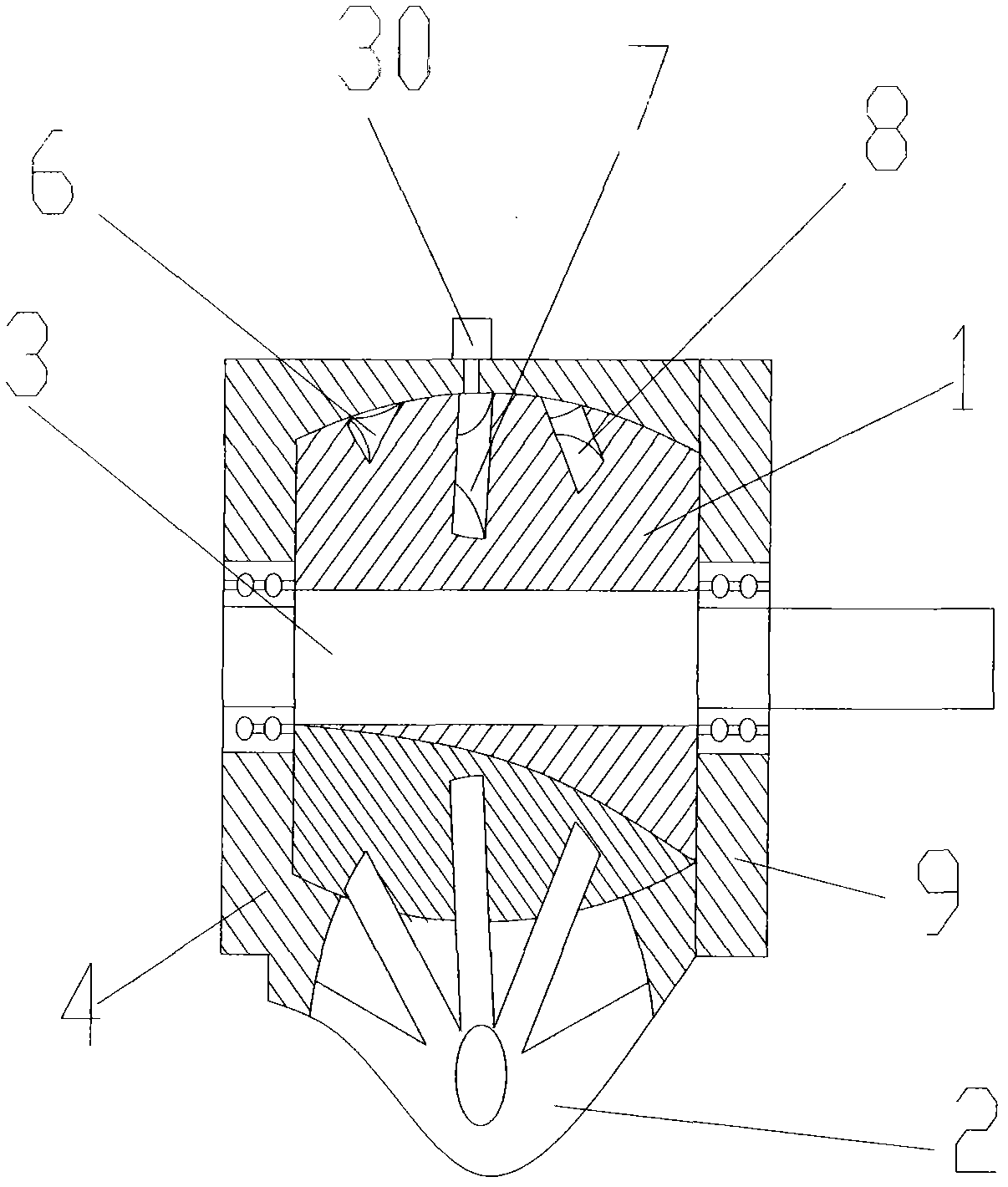

[0031] According to the single-screw engine embodiment shown in Figures 1, 2 and 3, the single-screw engine consists of a screw 1, two star wheels 2 engaged with the screw, screw shaft 3, star wheel shaft 15 and body 4 and the like. Because the screw rotor 1 has only one so it is a kind of single-screw engine. The screw 1 is installed on the screw shaft 3 , and the screw shaft 3 is installed in the machine body 4 through the bearing 10 . The two star wheels 2 are installed on the star wheel shaft 15 respectively, and the star wheel shaft 15 is supported in the machine body 4 through bearings and installed on both sides of the screw rod 1 and engaged with the screw rod 1 . The engine block also includes two intake ports 16 and two exhaust ports 18, and the fuel nozzle 17 matches the intake ports 16.

[0032] The two suction cylinders 6 of the engine are formed by the teeth of the star wheel 2 and the body 4 or the screw cylinder liner installed in the body 4 when the screw gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com