Stabilizing device for tin bath hot-end glass strip

A technology for stabilizing device and glass ribbon, applied in the field of improved devices for float glass forming, can solve problems such as poor lateral stability of glass ribbon, and achieve the effects of good stabilization effect, improved production quality and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

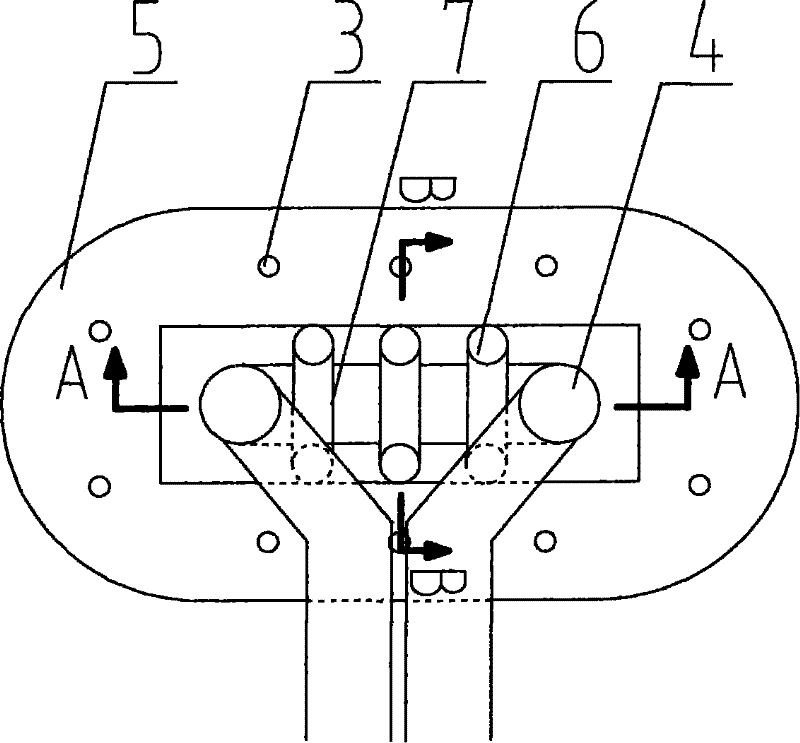

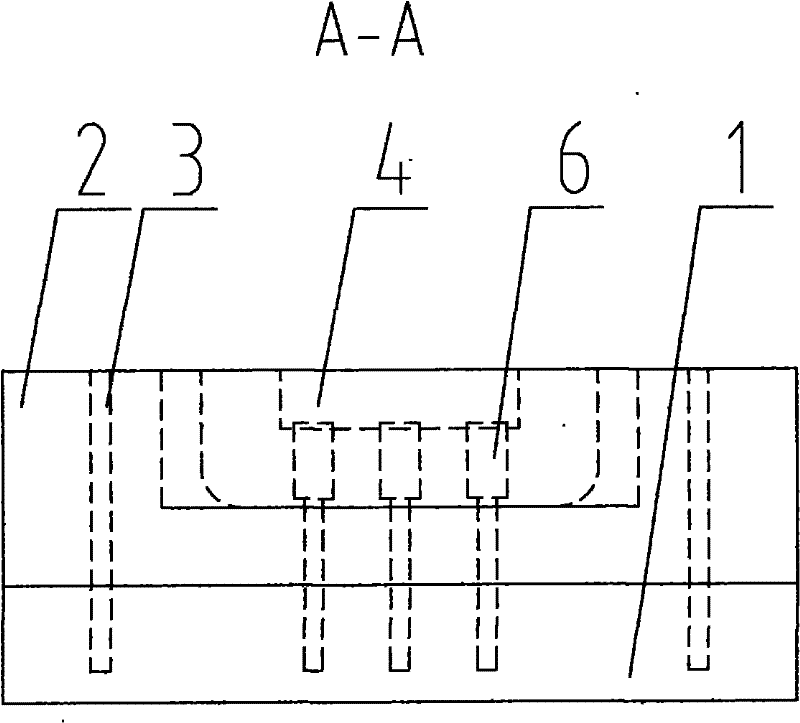

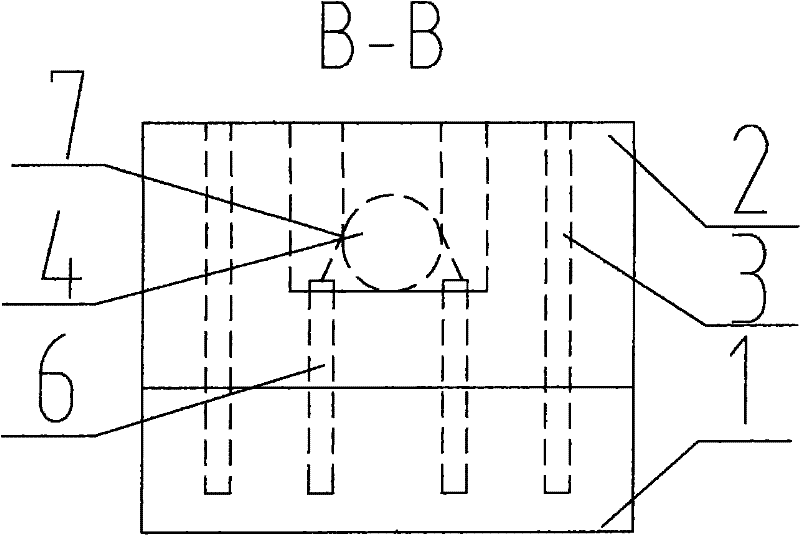

[0011] Referring to the accompanying drawings, the technical solution adopted by the present invention is: a stabilizing device for the glass ribbon at the hot end of the tin bath, which is fixed inside the tin bath. A graphite device 2 containing a groove of tin-lead mixed melt is arranged on the seat 1, and a cooling device is arranged in the groove of the graphite device 2.

[0012] In the technical solution of the present invention, the cooling device is a cooling water pipe 4, which is arranged at the lower part of the groove by means of the metal tungsten thin sheet firmware 7 wrapped in the outer layer and the fastening bolt 6, and the cooling water pipe 4 is connected with the matching cold water supply device .

[0013] In the technical solution of the present invention, the cooling water pipe 4 is arranged vertically in the groove of the graphite device 2 using a U-shaped loop.

[0014] In the technical solution of the present invention, the base 1 is made of refrac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com