Bearing device and rotary machine

A bearing device and bearing box technology, applied in the field of rotating machinery, can solve problems such as insufficient following, and achieve the effect of preventing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

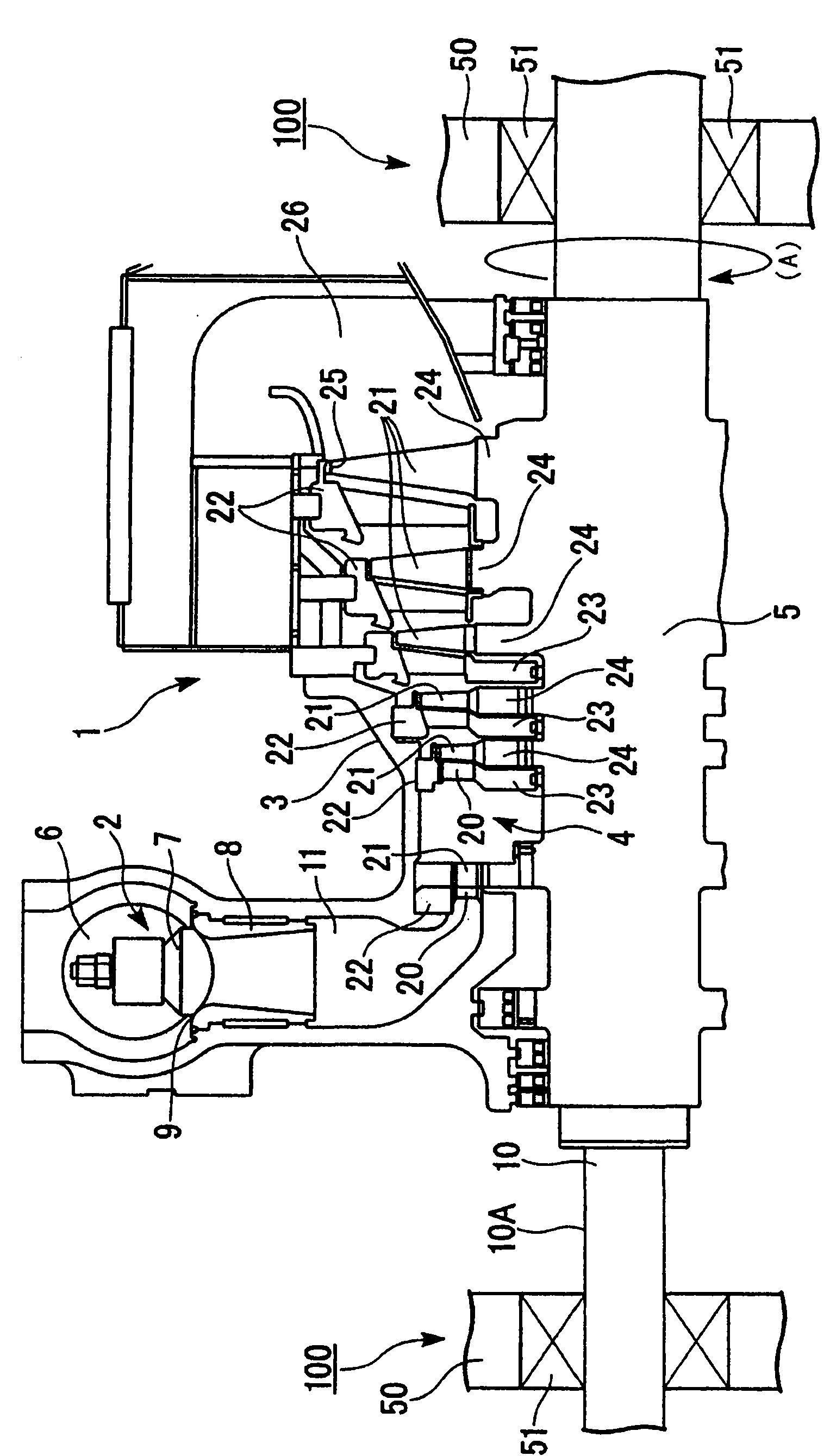

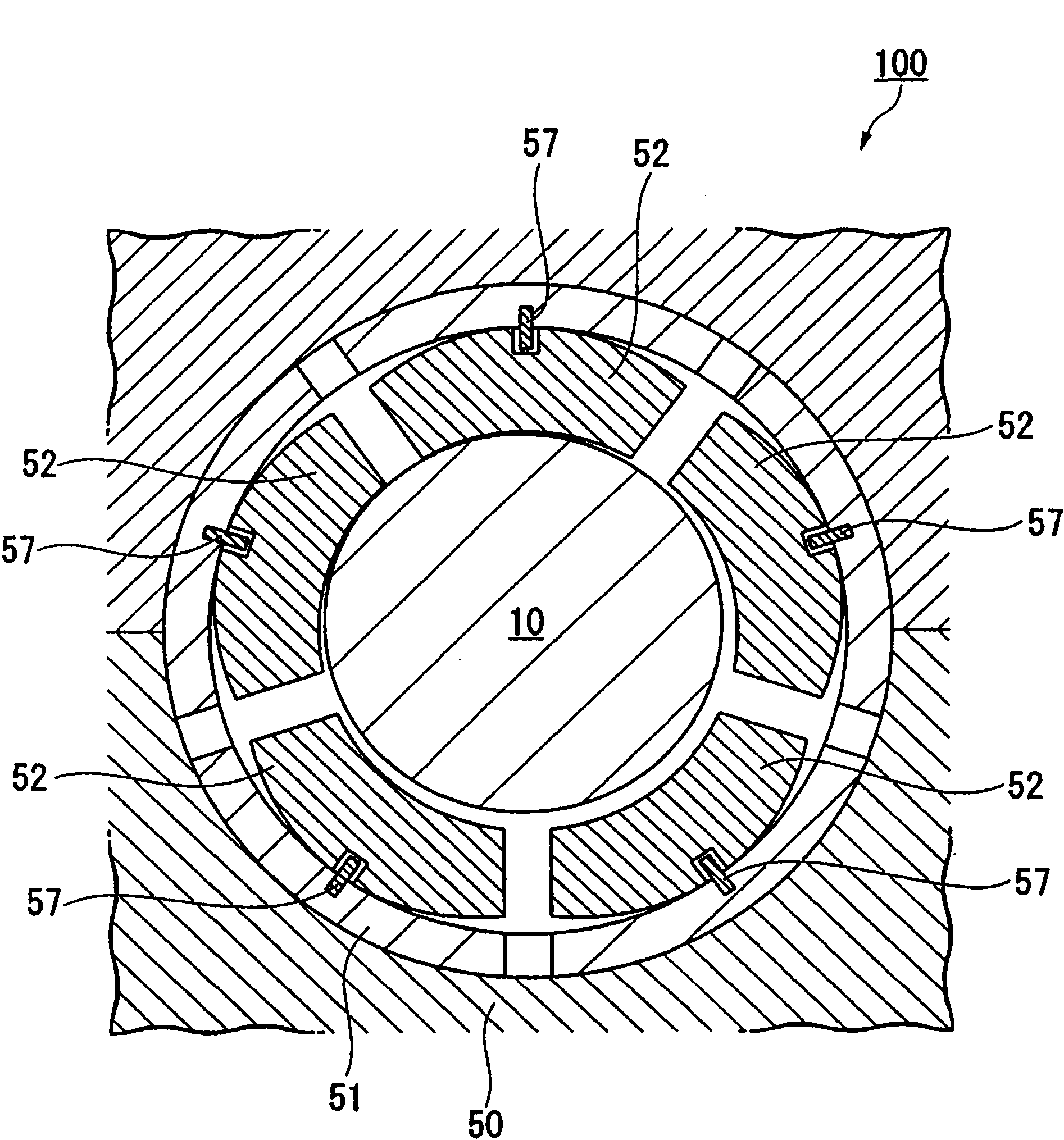

[0053] according to Figure 1 ~ Figure 3 The first embodiment of the present invention will be described. figure 1 A steam turbine 1 is shown as an example of a rotating machine equipped with the bearing device according to the present embodiment. The main structure of the steam turbine 1 includes: a regulating valve 2 for adjusting the amount and pressure of the steam (working fluid) flowing into the steam turbine 1; a casing (casing) 3 for maintaining the pressure; a power generating part 4 for generating power; To the rotor 5 of machines such as compressors.

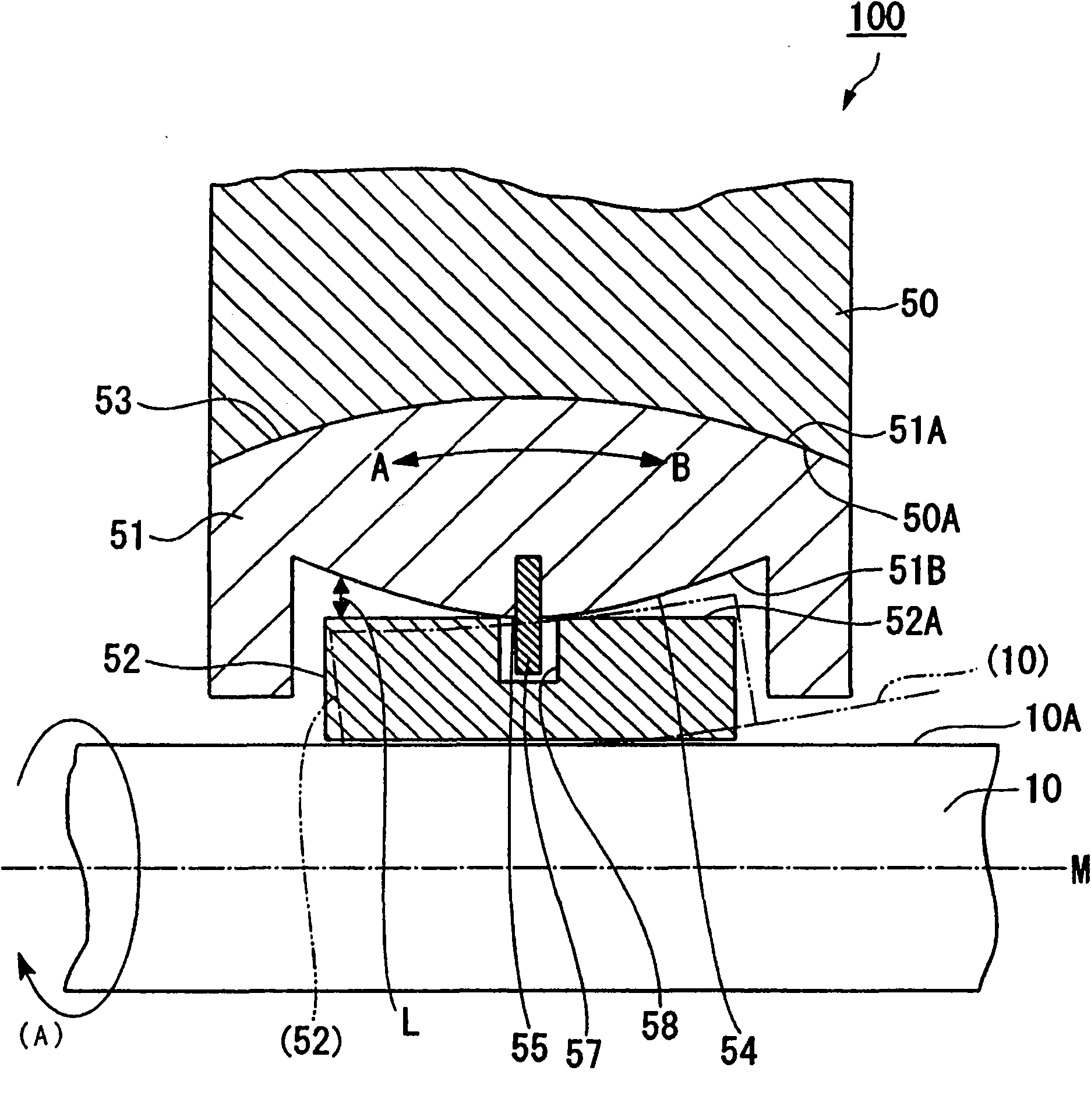

[0054] A plurality of regulating valves 2 are installed inside the housing 3 , and each has a regulating valve chamber 6 , a valve body 7 , and a valve seat 8 through which steam flows from a boiler (not shown). The valve seat 8 is substantially cylindrical, and its axis is perpendicular to that of the rotor 5 . In addition, in the rotor 5, the rotating shaft 10 thereof is supported by a journal bearing device 100...

no. 2 approach

[0070] refer to Figure 6 A second embodiment of the present invention will be described. The structure of the journal bearing device 101 of the present embodiment is different from that of the journal bearing device 100 of the first embodiment in the shape of the inner peripheral surface 51B of the bearing housing 51 . That is, the inner peripheral surface 51B of the bearing housing 51 is a curved surface along the axis M, and the central portion of the curved surface has a shape protruding inward toward the rotating shaft 10 side, and the top of the protruding portion of the curved surface is formed so as to be aligned with the axis M. M is substantially parallel to the flat surfaces 56 .

[0071]Therefore, according to such a journal bearing device 101 , in the normal case where the rotating shaft 10 is not deformed into a bow shape with respect to the axis M thereof, the flat surface 56 at the center of the inner peripheral surface 51B of the bearing housing 51 allows the...

no. 3 approach

[0074] refer to Figure 7 and Figure 8 A third embodiment of the present invention will be described. Such as Figure 7 As shown, the journal bearing device 102 of the present embodiment is different in structure from the journal bearing device 100 of the first embodiment in the position of the pivot shaft 60 which is a supporting member for supporting the pad 52 on the bearing housing 51 . The pivot 60 is arranged such that its base end is fixed to the axial end on the inner peripheral surface 51B side of the bearing housing 51 and its front end protrudes from the inner peripheral surface 51B, and its front end is inserted into an opposing bearing bush. 52 in the recess 61 formed by the outer peripheral surface 52A. Therefore, the bearing bush 52 is positioned relative to the bearing housing 51 in the axial direction and around the shaft (in the direction of the arrow (A)) by the engagement of the pivot shaft 60 and the concave portion 61 . Furthermore, a clearance 62 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com