Cap and container with cap

A container and container mouth technology, which is applied in the field of lids and containers equipped with the lids, can solve problems such as airtight leakage, and achieve the effects of simple structure, optimized embedding condition, and improved sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

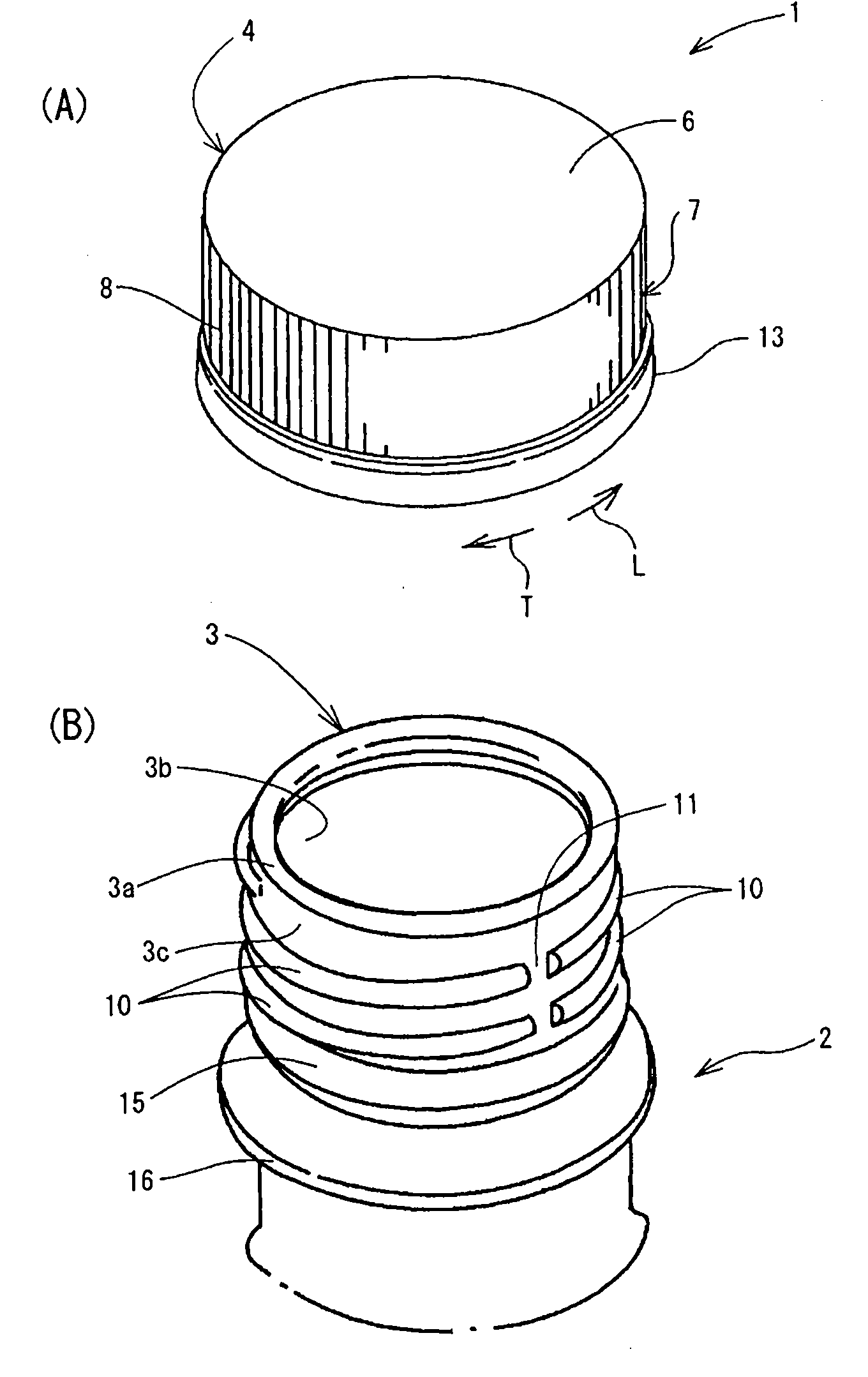

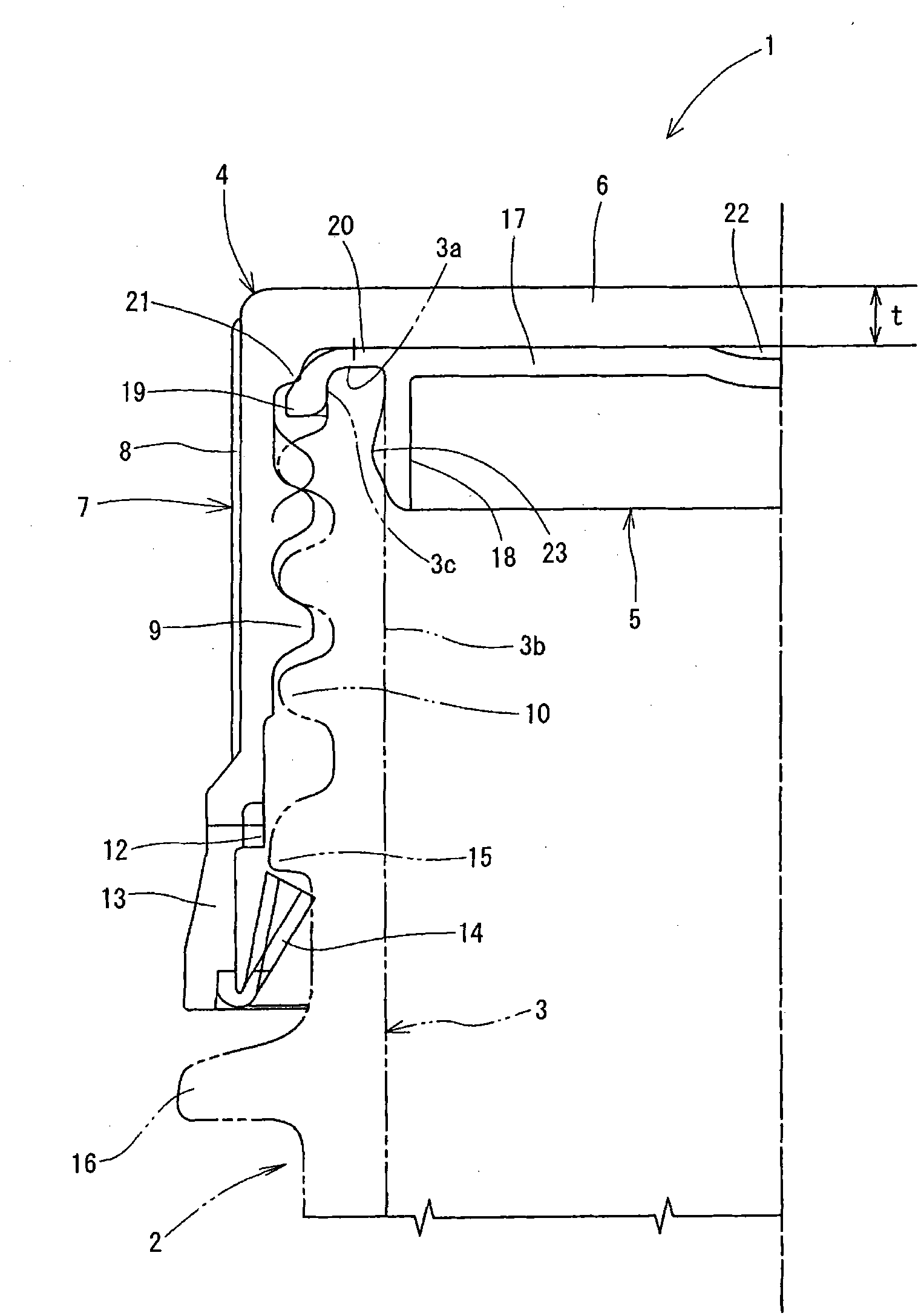

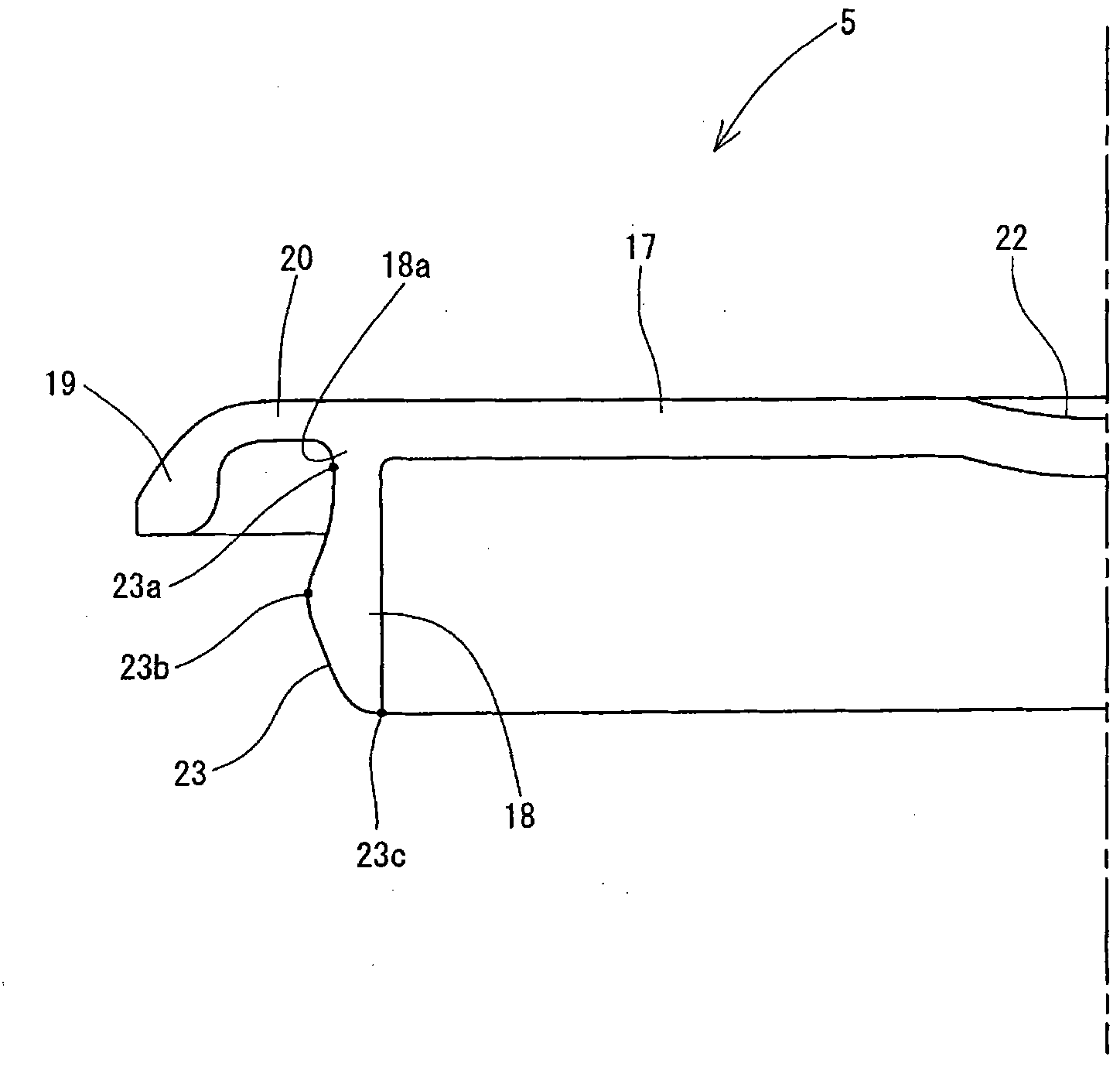

[0039] Below, while referring to the attached Figure 1 Embodiments of the present invention will be described. here, figure 1 (A) and (B) are perspective views schematically showing the structure of a main part of a cap 1 and a container 2 including the cap 1 according to one embodiment of the present invention, figure 2 It is a semi-longitudinal cross-sectional view schematically showing the structure of the lid 1 (a figure showing the left half of a roughly bilaterally symmetrical vertical cross-section), image 3 It is a semi-longitudinal cross-sectional view schematically showing the structure of the gasket 5 of the cap 1 (a diagram showing the left half of a left-right symmetrical longitudinal cross-section).

[0040]Such as figure 1 As shown in (A) and (B), the cap 1 according to this embodiment is attached to the mouth 3 of a container (such as a PET bottle) 2 manufactured separately from the cap 1, and the cap 1 is injection-molded Or formed by compression mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com