Length-adjustable shaft

A technology for adjusting shafts and shaft parts, which is applied in the field of adjustable length shafts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

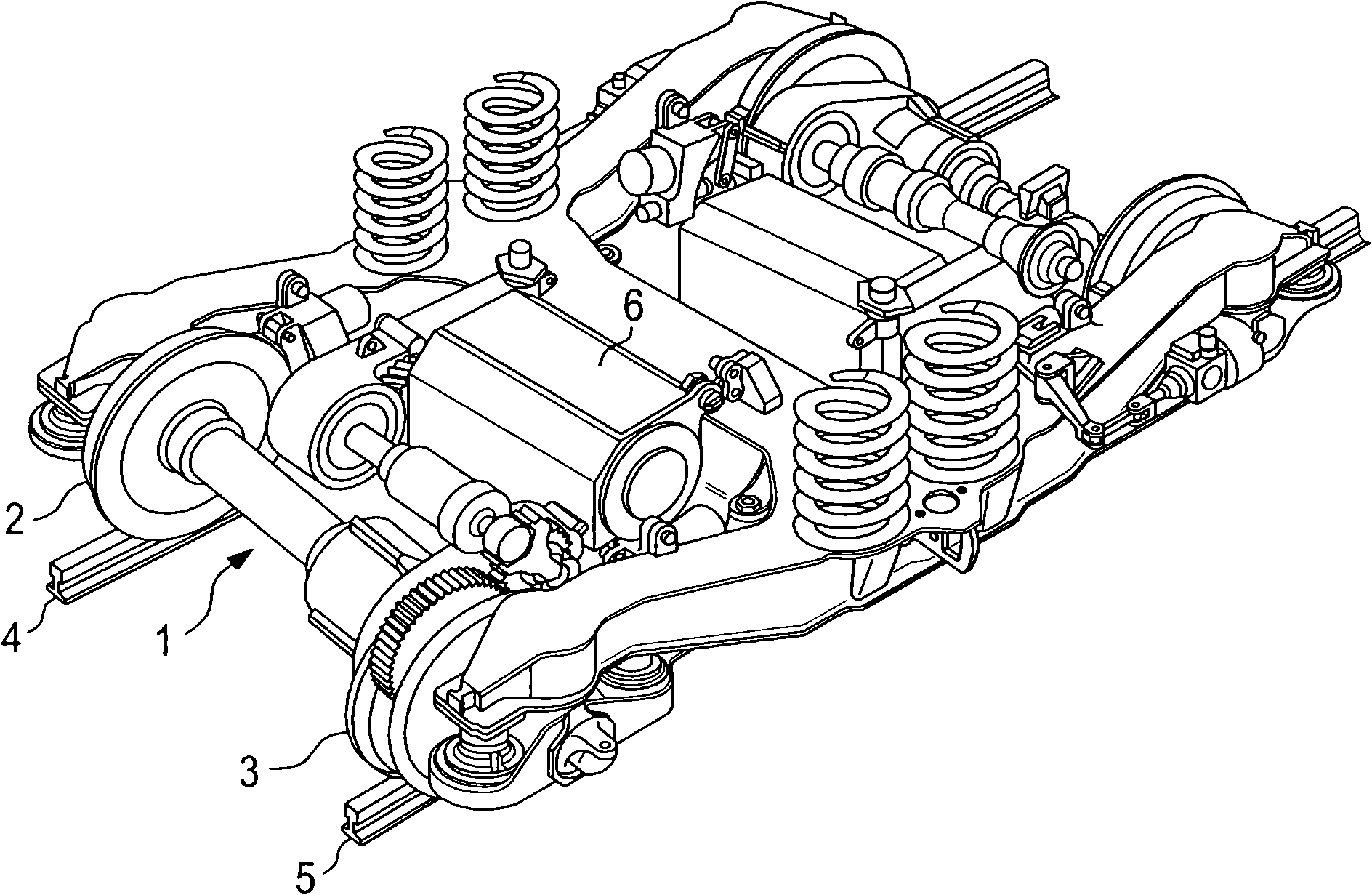

[0019] for such as figure 1 The wheel set of the rail vehicle shown in includes two axles, of which only axle 1 is discussed here. The length of shaft 1 is adjustable. The shaft supports the wheels 2, 3 at its two ends respectively. Wheel can roll on guide rail 4,5.

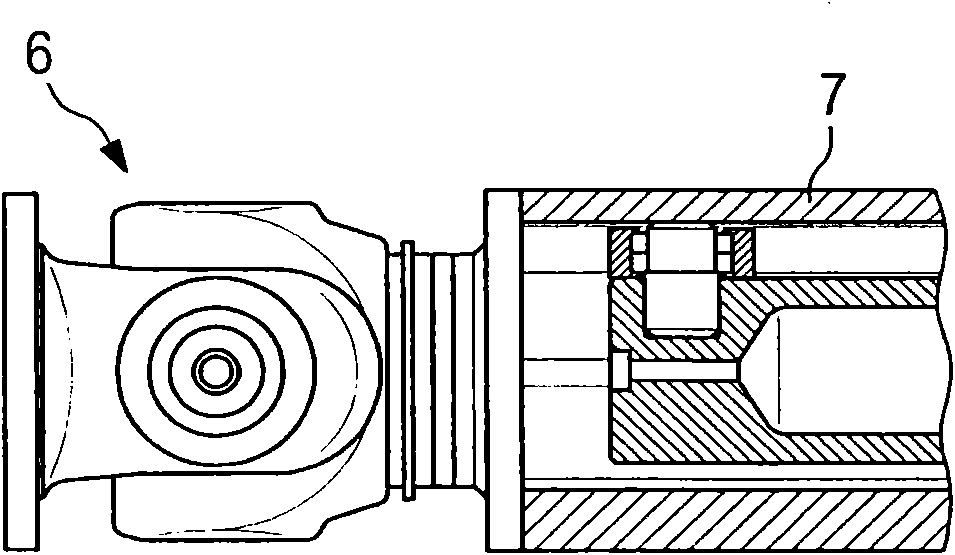

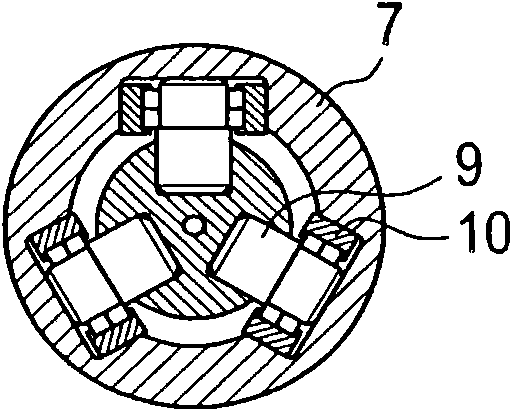

[0020] A universal joint 6 is arranged in front of each wheel 2,3. The shaft 1 comprises an outer shaft part 7 and an inner shaft part 8 . The shaft portion 7 is sleeve-shaped. It rests on the inner shaft part 8 via three bearings. image 3 Three bearings (tripod) are shown in cutaway view. The inner shaft portion 8 comprises a blind hole. A bearing pin 9 is embedded in each blind hole. It supports the roller bearing 10 . Roller bearings 10 engage in longitudinal grooves of the outer shaft portion 7 .

[0021] The three roller bearings 10 thus roll in the longitudinal grooves during the telescopic movement of the outer shaft part 7 and the inner shaft part 8 .

[0022] Figure 4 The configuration of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com