High-temperature gate valve of combined wedge plate

A high-temperature gate valve and gate technology, applied in the field of combined gate high-temperature gate valves, can solve the problems of increasing valve switching torque, reducing valve service life, friction and wear, etc., and achieving the effect of reducing valve switching torque and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

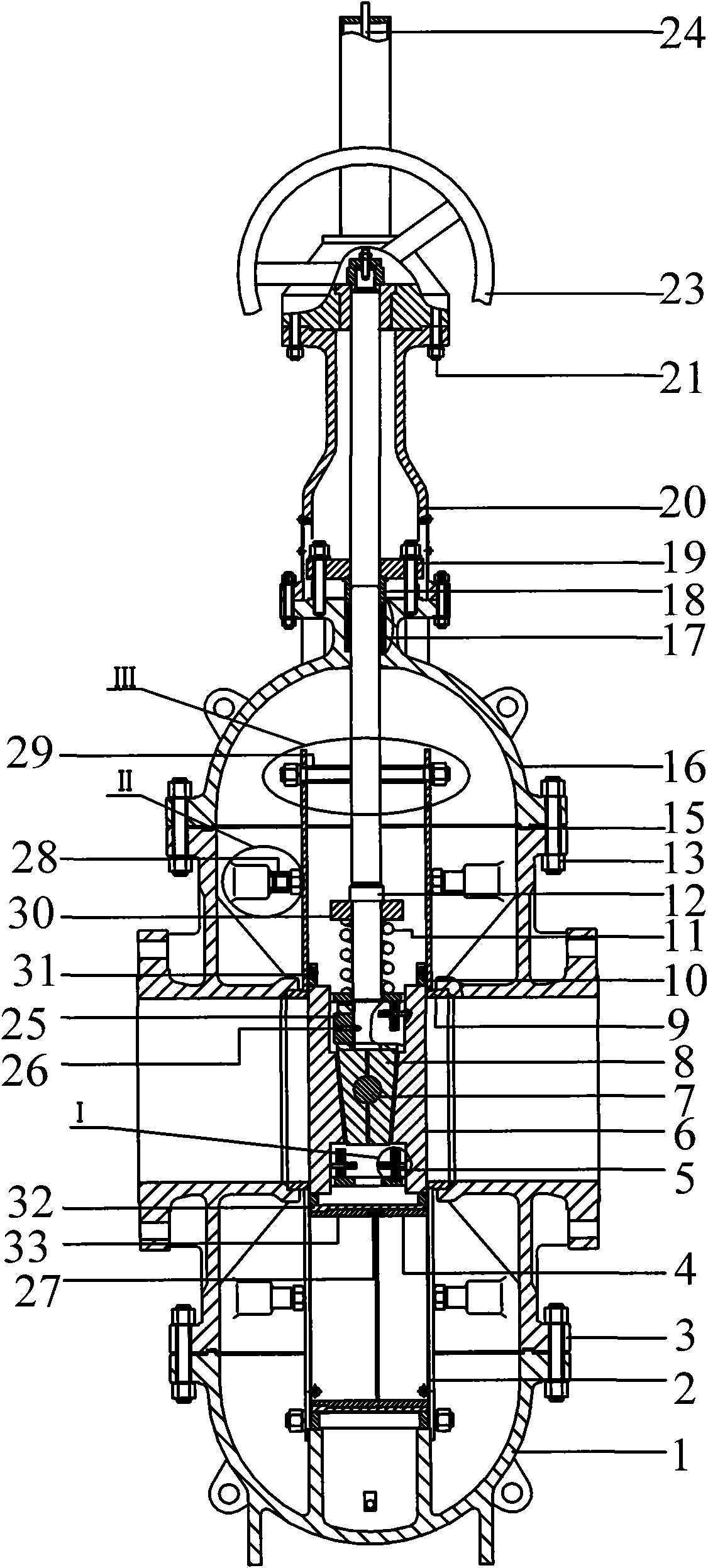

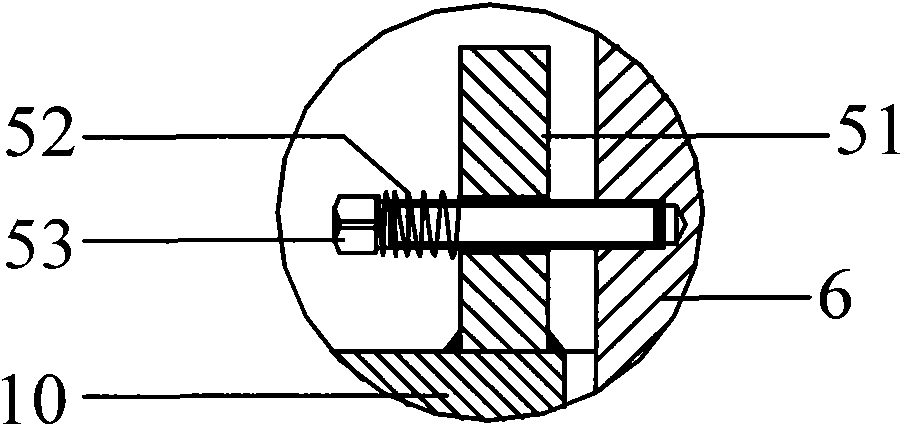

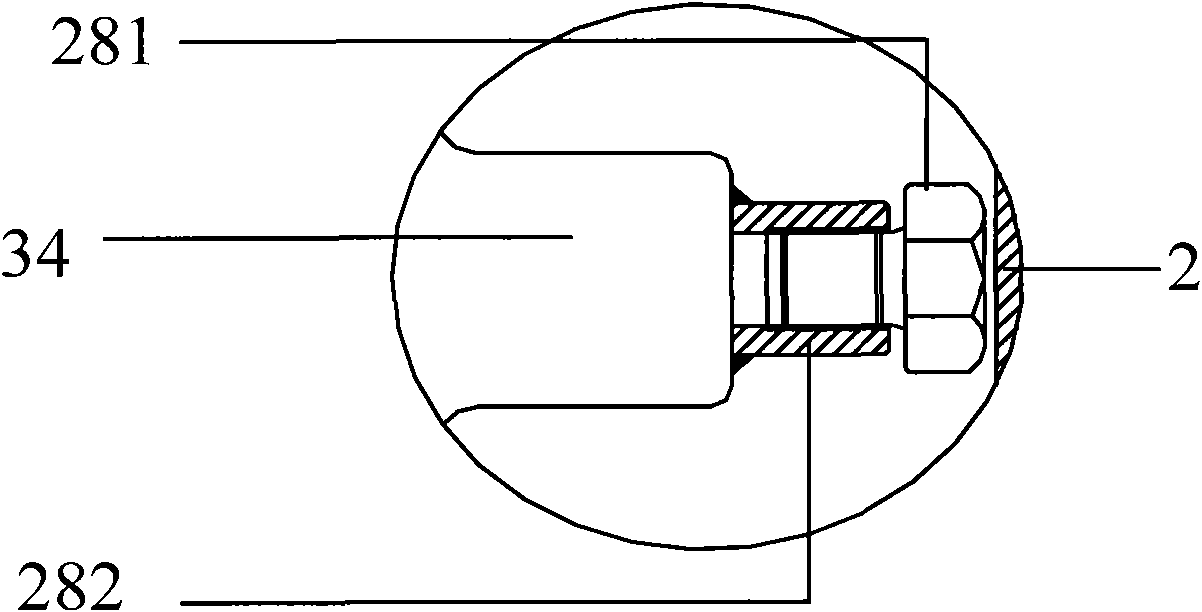

[0019] Such as figure 1 As shown, the combined gate high temperature gate valve of the present invention includes a lower cover 1, a guide plate 2, a valve body 3, a first guide tube 4, an elastic fixing mechanism 5, an outer gate 6, a steel ball 7, an inner gate 8, a valve Seat 9, gate frame 10, first spring 11, valve stem 12, first bolt 13, sealing gasket 15, upper cover 16, sealing packing 17, packing gland 18, packing pressure plate 19, bracket 20, the first Two bolts 21, valve driving device 23, indicator rod 24, joint 25, set screw 26, cylindrical spring 27, outer righting mechanism 28, inner righting mechanism 29, spring pressing plate 30, roller mechanism 31, fixed cylinder 32 and the second Two guide tubes 33. The lower cover 1 is fixed to the valve body 3 by bolts, the upper cover 16 is fixed to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com