Hanging basket device for closure construction of continuous box girders

A technology for closing sections and box girders, which is applied in bridges, bridge construction, erection/assembly of bridges, etc. It can solve the problem that the hanging basket device cannot be returned, and achieve the effect of simple structure, easy operation and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

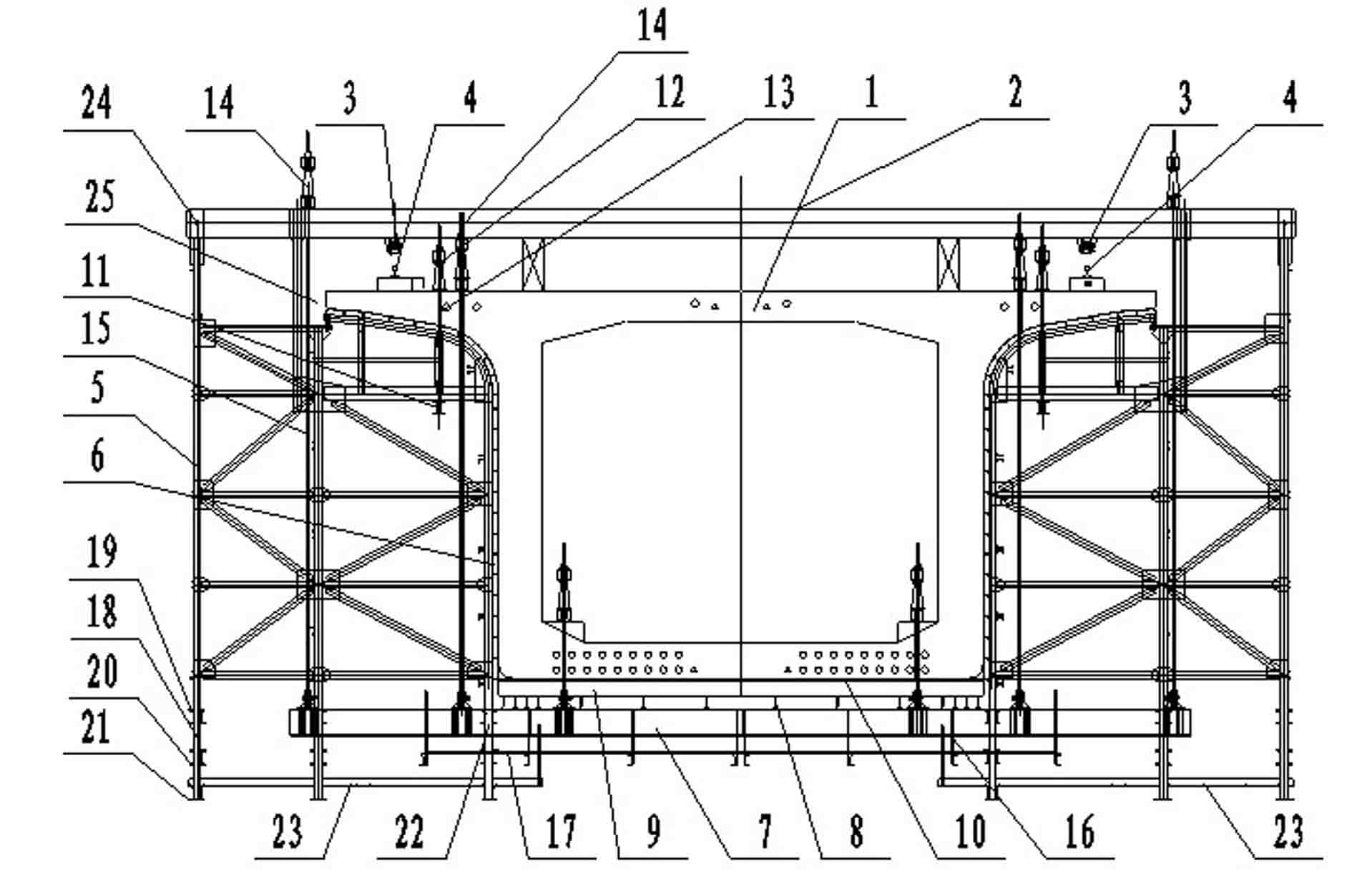

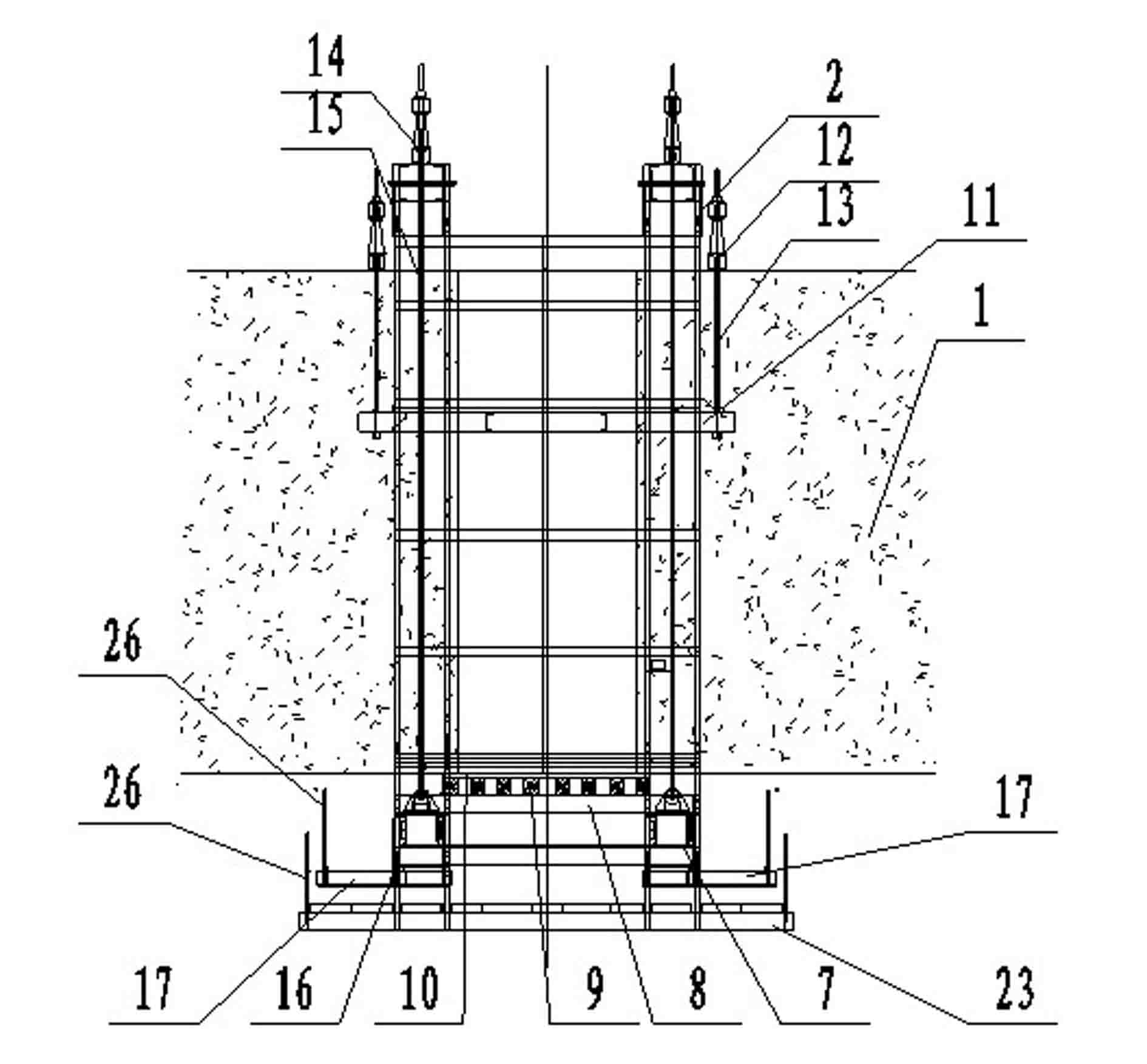

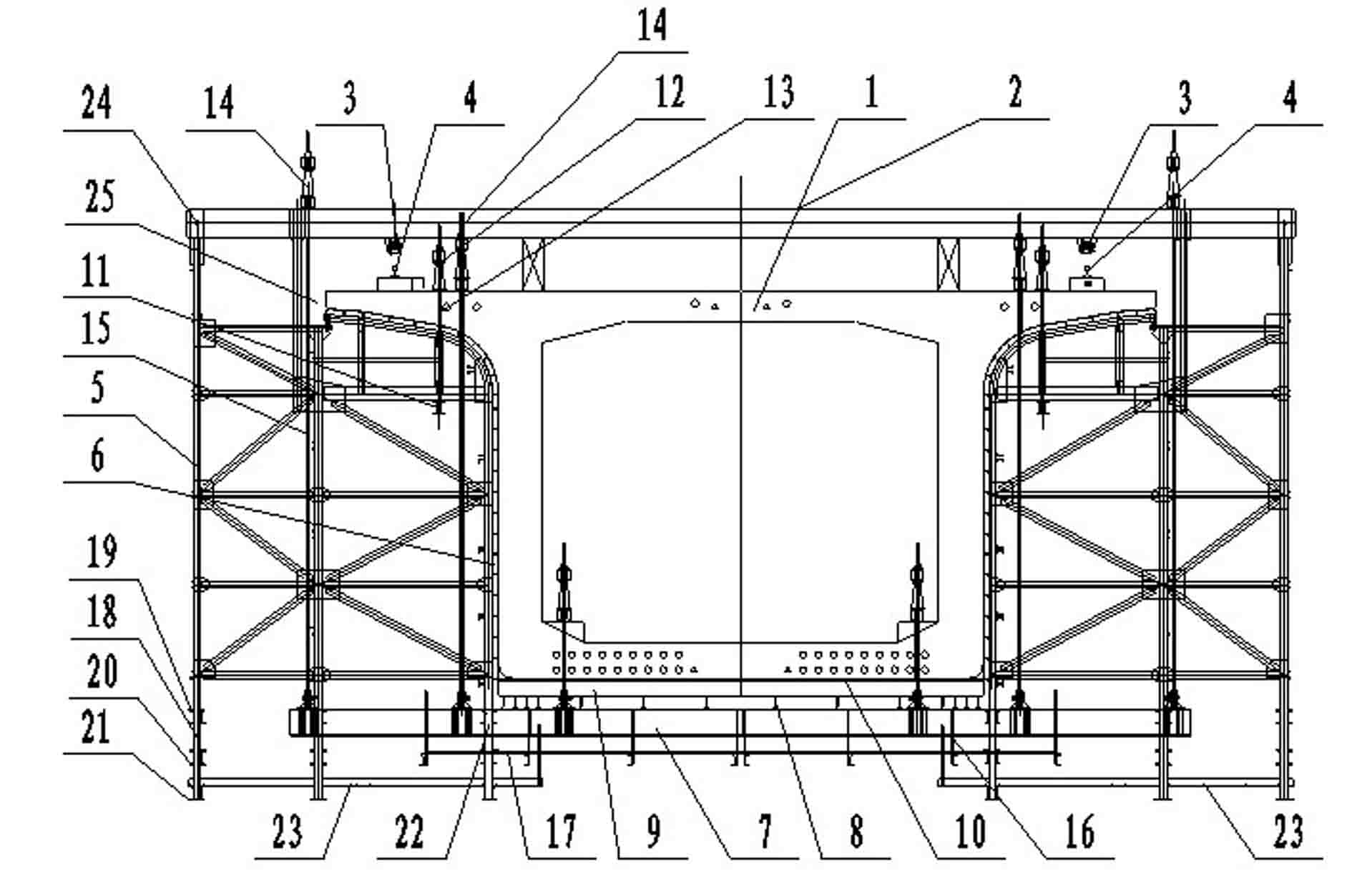

[0011] A hanging basket device for the construction of the closing section of the continuous box girder, such as figure 1 , 2 As shown, it includes the top beam 2 above the continuous box girder 1, the road wheels 3 installed on both sides below the top beam, and the steel rail 4 installed on the beam surface of the continuous box girder 1 and opposite to the road wheels 3; The outer formwork trusses 5 and outer formwork 6 suspended on both ends of the top beam 2, and the bottom formwork beams 7, bottom formwork longitudinal beams 8, bottom formwork square timbers 9 and bottom formwork 10 at the bottom of the continuous box girder 1, the outer formwork trusses 5 The lower part is provided with an outer mold load-bearing crossbeam 11, and the outer mold load-bearing beam 11 is suspended by the two ends of the outer mold jack 12, the outer mold suspender 13 and the top beam 2; the two ends of the bottom mold beam 7 pass through at least one bottom mold jack 14 and At least one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com