Aminated alginic acid and preparation method thereof

An alginic acid and amination technology, applied in the field of aminated alginic acid and its preparation, can solve the problems of fast curing speed, slow biodegradation and poor stability of calcium alginate gel, and achieve good plasticity, promote regeneration, and stabilize good effect

Inactive Publication Date: 2010-12-29

RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

View PDF2 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

This technology improves how we use alginate instead of other biopolymers for making medical devices that have better compatibility than traditional polymer solutions such as polysaccharides or sutures made from them. By modifying certain parts of these molecules together through chemical reactions, this new solution becomes more effective when compared to older methods like glue bondings. Additionally, there're also advantages over existing products due to their ability to form stable structures under physiological conditions (temperature). These technical benefits make alginate an ideal choice for creation of implants suitable for different types of applications where they could help heal damaged areas around joints.

Problems solved by technology

This patents discuss how certain types of material called alginates may help heal damaged areas more efficiently when they come into contact with blood vessels during surgeries due to their ability to absorb liquor quickly without causing damage on surrounding organs like heart muscle. Additionally, these materials could potentially contain drugs released within minutes after being implanted inside patients' bodies. These technical problem addressed in this patented text include finding ways to create small injection devices containing alginics suitable for use as temporary replacements for hard-to-reach spinal fusion procedures while maintaining sufficient stability over long periods under physiological conditions.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

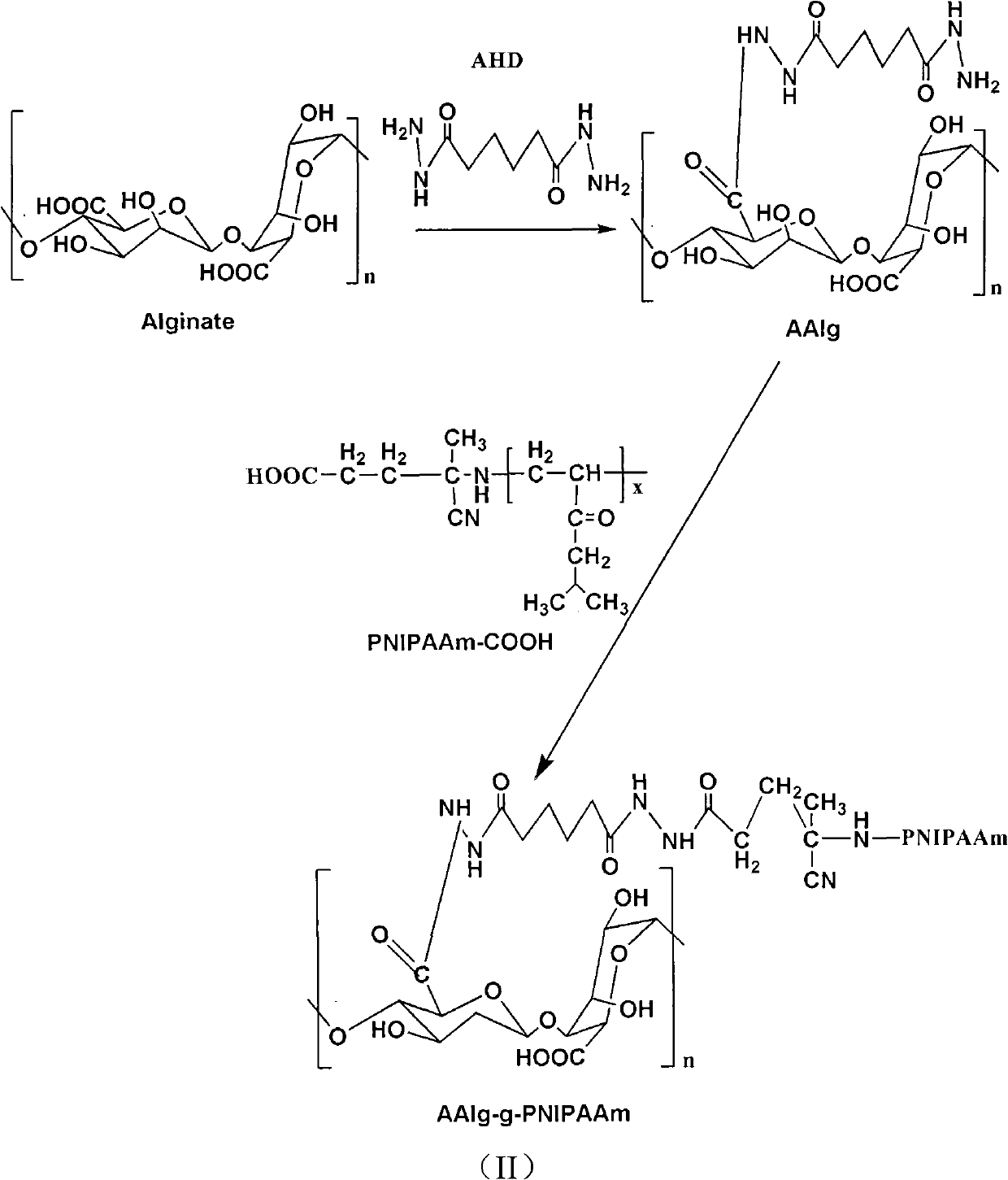

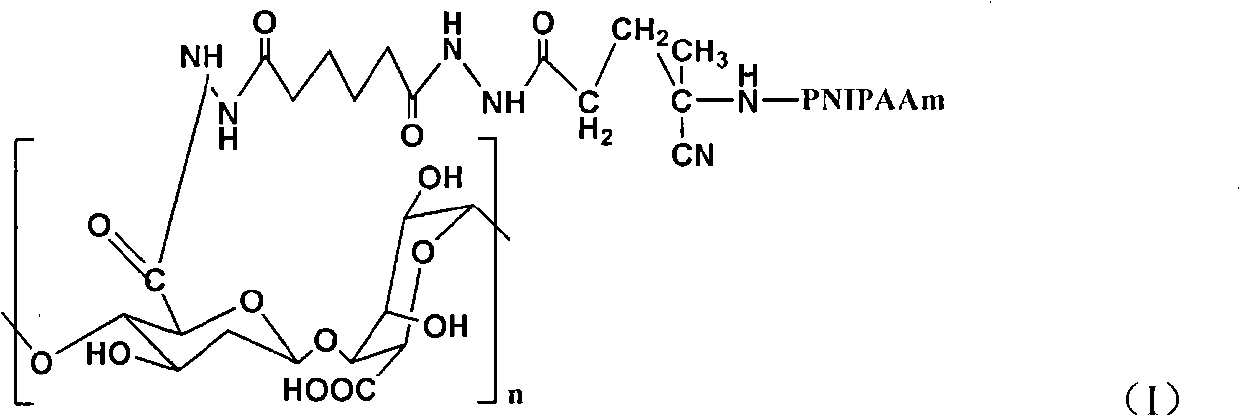

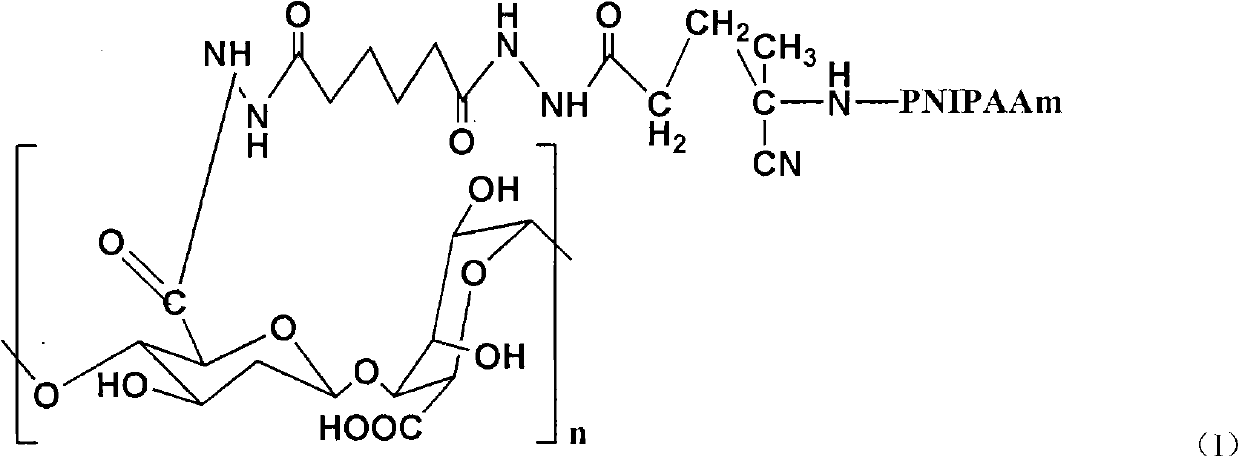

The invention relates to aminated alginic acid which is grafted by poly(N-isopropylacrylamide). The aminated alginic acid has the chemical structural formula shown as in a formula (I). The preparation method mainly comprises the following steps of: obtaining sodium alginate with the average molecular weight of 6,000-20,000 by adopting gamma ray to irradiate the sodium alginate; subjecting the sodium alginate and ADH (Antidiuretic Hormone) to the reaction in a solution system of a DMSO (Dimethylsulphoxide) water solution dissolved with EDC (Ethylidene Dichloride) and HOBt (I-hydroxybenzotriazole) to form an aminated alginic acid AAlg intermediate product; and subjecting the aminated alginic acid AAlg intermediate product and a PNIPAAm-COOH solution to a grafting reaction for a certain timeand finally dialyzing a polymerized product with the molecular weight of over 20,000. The aminated alginic acid is applicable to preparing bone-repairing materials, controlled-release drugs, cell micro-capsules, tissue engineering scaffolds, wound assistants and the like. The invention has the characteristics of body temperature sensitiveness, favorable plasticity, degradability, capability of promoting the regeneration of bone defect, favorable stability, high safety and the like.

Description

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Owner RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap