Movable automatic powder spraying system

A powder spraying and automatic technology, applied in the direction of spraying devices, etc., can solve the problems of immature technology, low spraying pass rate, spraying powder flying, etc., to achieve the effect of ensuring the quality of the coating, improving the quality of the coating, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

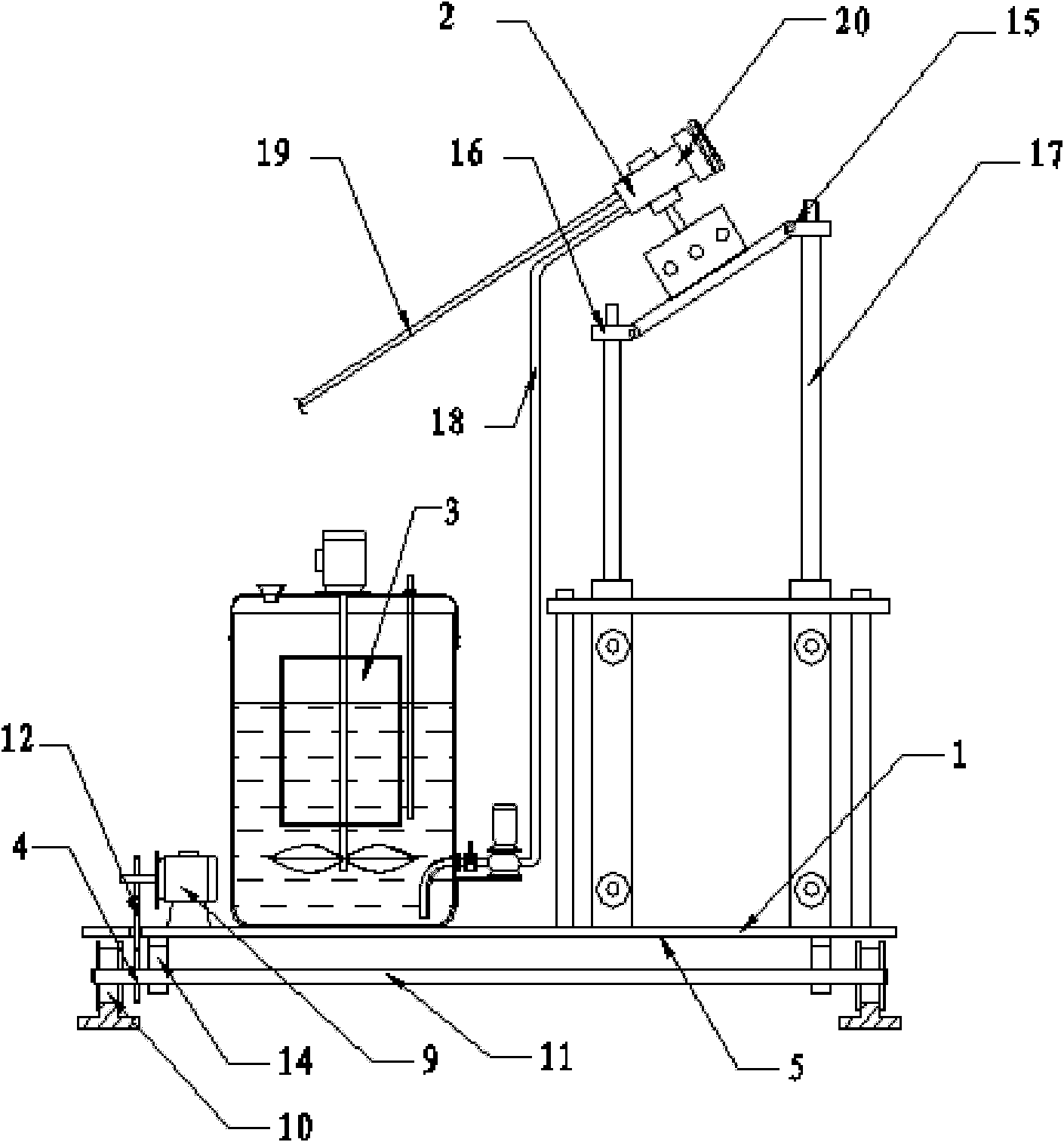

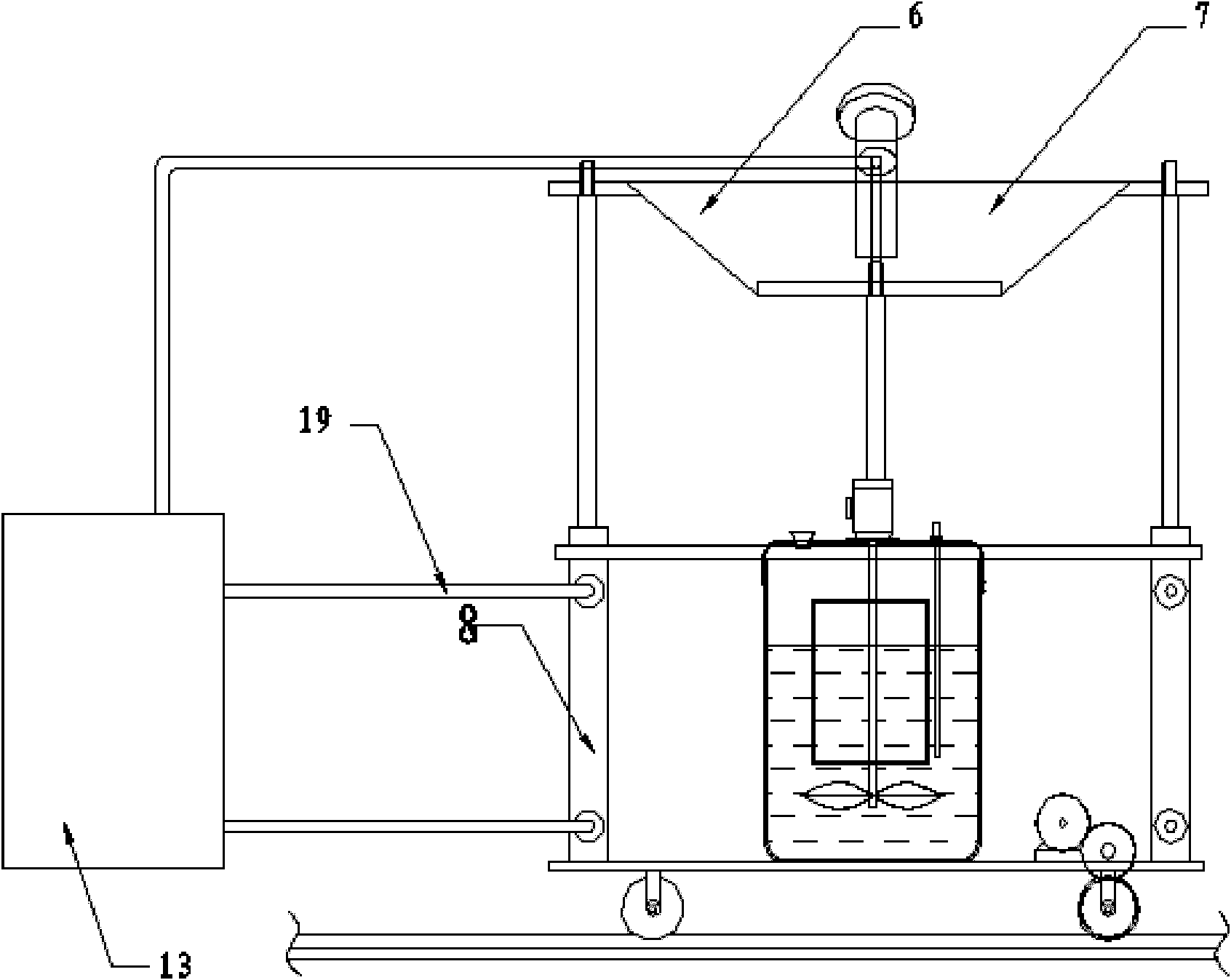

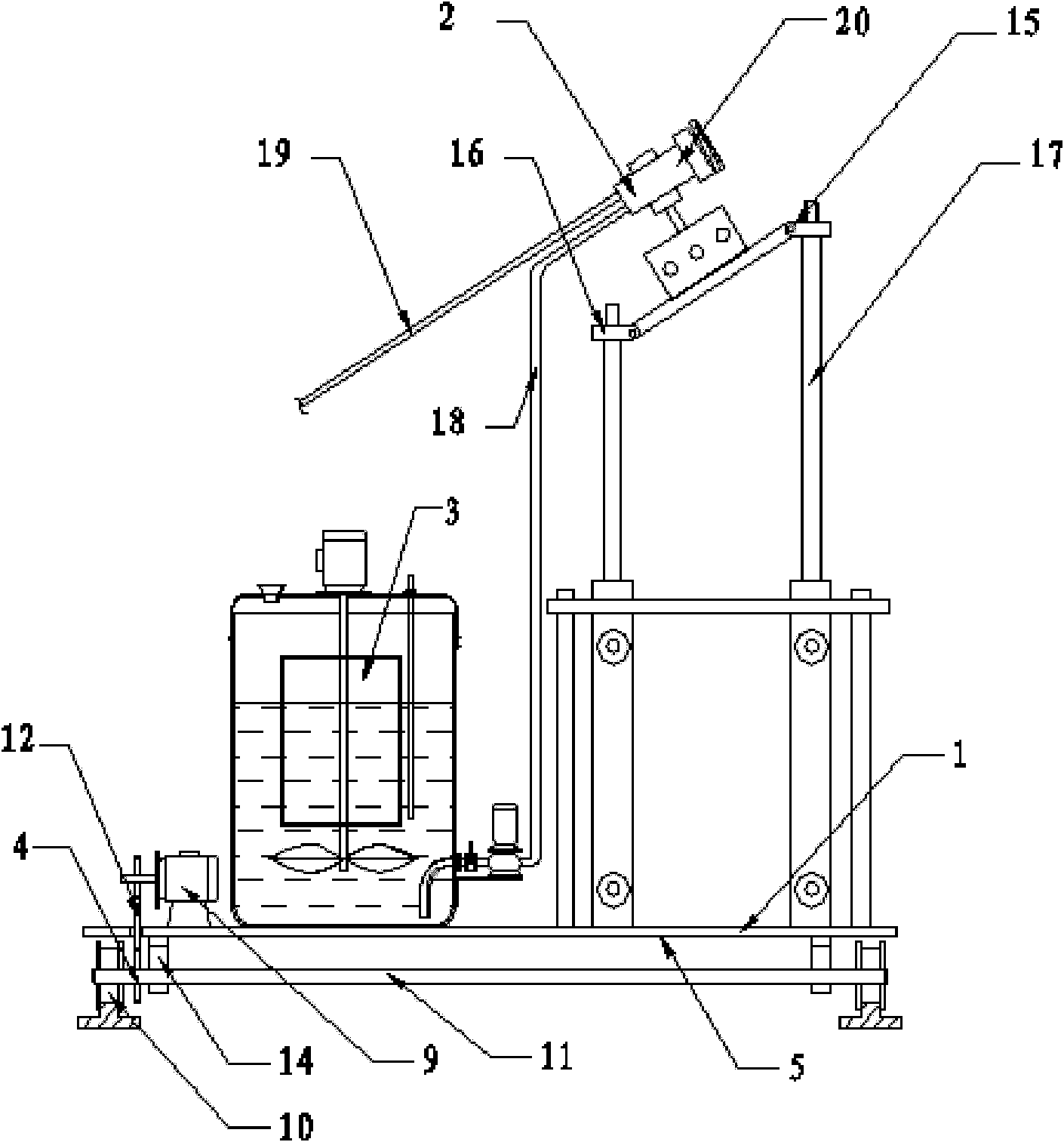

[0011] Such as figure 1 , figure 2 As shown, a kind of movable automatic powder spraying system that present embodiment provides, it comprises mobile support 1, spray gun 2, powder supply system 3 and mobile device 4, is provided with mobile device 4 at the bottom 5 of mobile support 1, in The mobile support 1 is provided with a powder supply system 3, a vertical cylinder 8, an angle adjustment plate 6 and a spray gun 2, the vertical cylinder 8 is fixed on the mobile support 1, the angle adjustment plate 6 is connected with the vertical cylinder 8, and the angle adjustment plate 6 The top 7 is provided with a spray gun 2 . In order to allow the powder spraying system to freely move and spray according to the shape and size of the workpiece, the mobile system 4 is composed of a mobile motor 9, a roller 10, a transmission rod 11, a transmission gear 12 and a fixed block 14, and the fixed block 14 is installed on the side of the mobile bracket 1 On the bottom 5, a transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com