Steel mesh and PCB (Printed Circuit Board)

A technology for printed circuit boards and stencils, which is applied to printed circuit components, printed circuits assembled with electrical components, printed circuits connected with non-printed electrical components, etc., which can solve the problem of wasting solder paste, high solder paste cost, component Problems such as position offset, suspension bridge, bridge, etc., achieve the effect of reducing soldering time, saving solder paste, and balancing tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

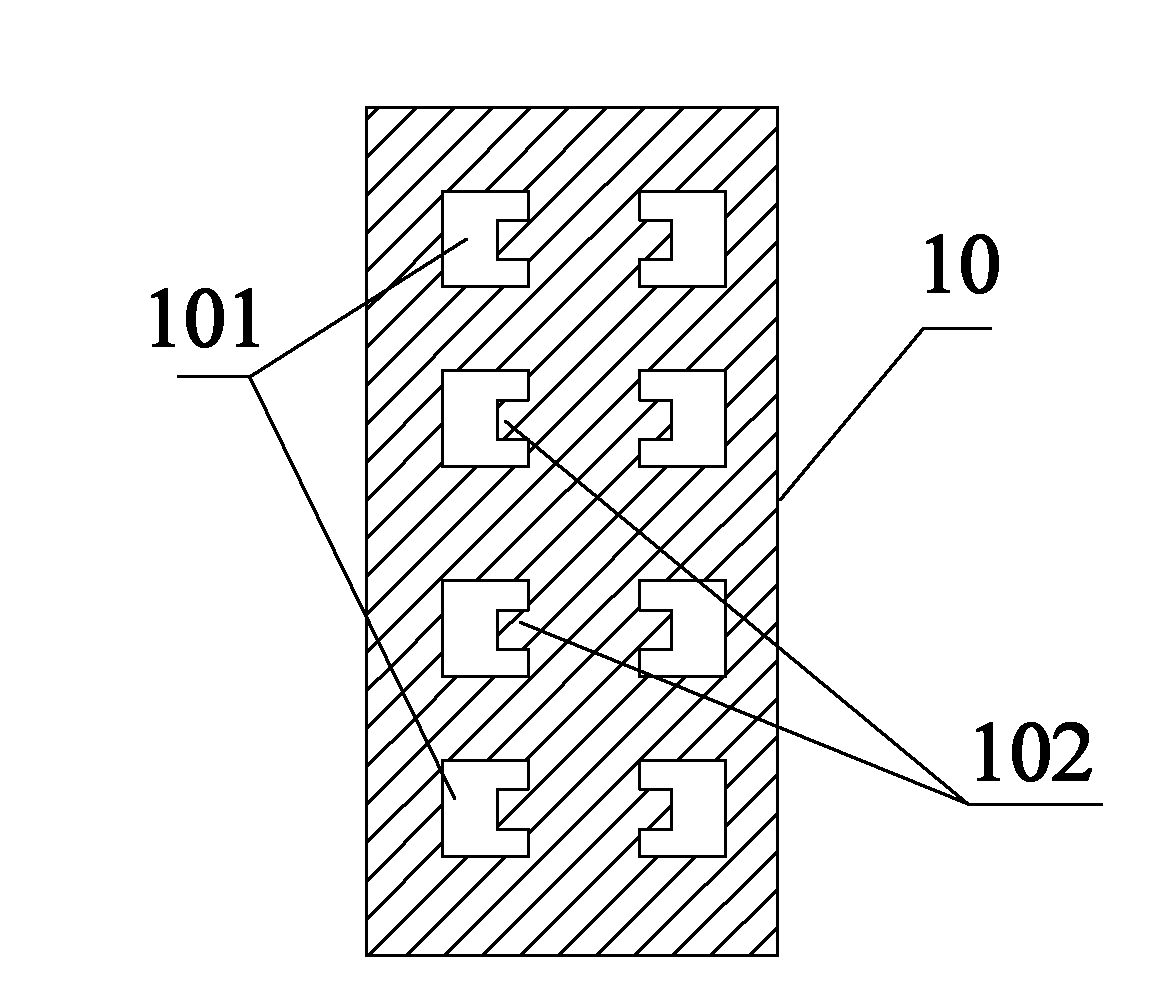

[0022] refer to Figure 1a , an embodiment of a stencil of the present invention is proposed, a plurality of holes 101 are provided on the stencil 10, and at least one bump 102 is arranged in the hole 101. In this embodiment, the above-mentioned bump 102 is set It is one, and the hole 101 is in the shape of "concave" after the protrusion 102 is set.

[0023] In the above embodiment, the shapes of the protrusions 102 provided in each of the holes 101 may be the same or different, that is, the shapes of the holes 101 provided on the same steel mesh 10 may be the same or not completely the same. In this embodiment The holes 101 are set to have the same shape and are symmetrically set on the steel mesh, and can be located in the middle inner position, and set according to actual application conditions.

[0024] Applying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com