Electromotor with brushes

A technology of electric motors and brushes, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve problems such as poor power supply, achieve the effects of reducing noise, reducing poor power supply, and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

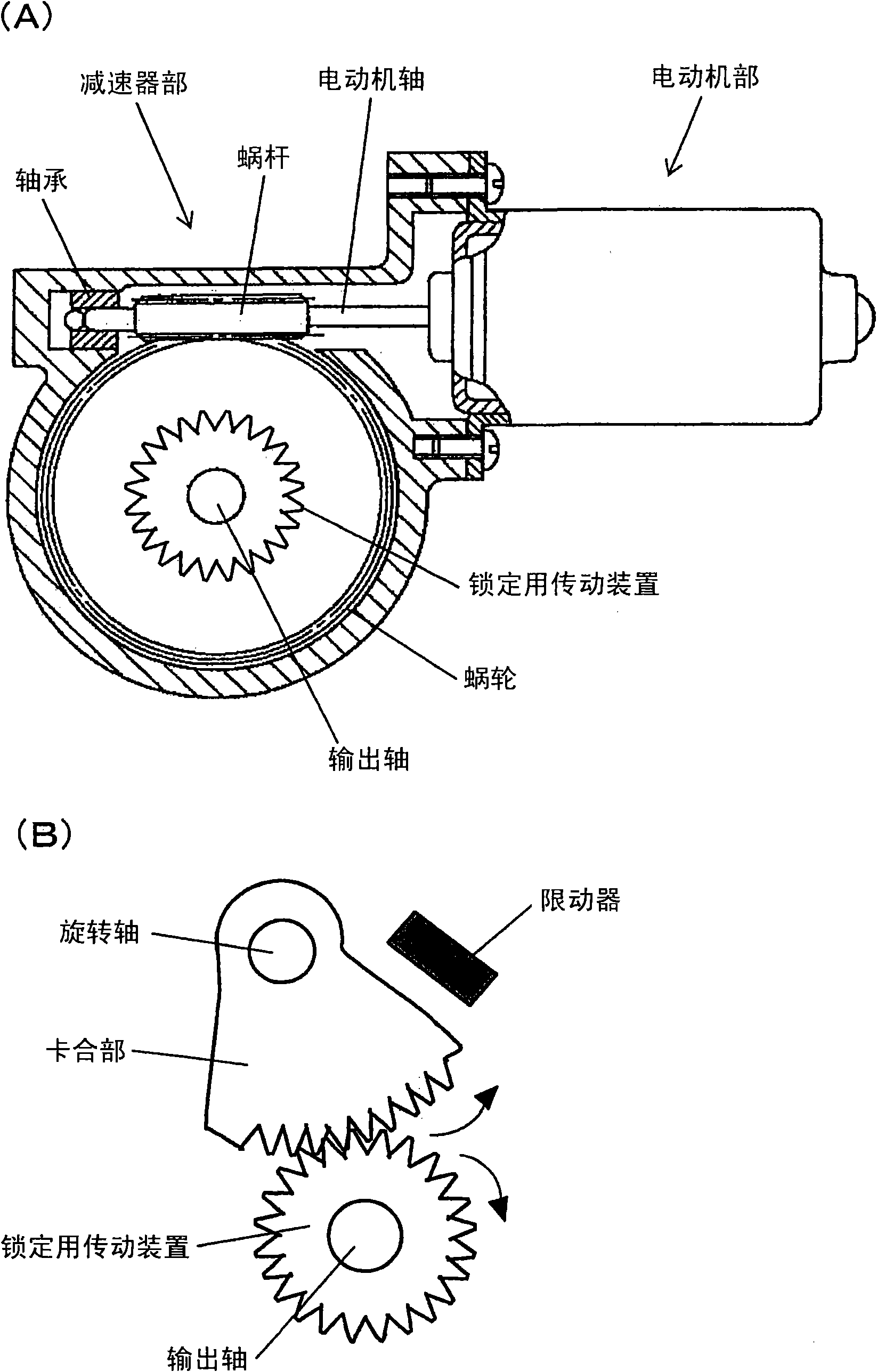

[0038] figure 1 It is a diagram illustrating a mechanical unit with a stop mechanism to which the present invention can be applied, (A) is an overall view of a brushed motor showing a worm reducer part in section, and (B) is an enlarged cross-sectional view showing a stop mechanism part. exist figure 1 In (A), the motor part is attached to the speed reducer part, and the front end part of the motor shaft is supported by the bearing shaft of the speed reducer part. The worm is fixed to the motor shaft. The worm wheel is meshed with the worm, so that the driving torque output from the motor part is transmitted from the motor shaft to the worm, and the driving torque is transmitted from the worm to the worm wheel in the speed reducer part, and the torque is taken out from the output shaft to the outside.

[0039] In the brushed motor shown in the figure, the stop mechanism includes: a locking actuator fixed to the output shaft and rotating together with the output shaft; an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com