Device for plugging valves of pressure vessel

A technology for pressure vessels and valves, applied to valve devices, engine components, mechanical equipment, etc., can solve problems such as complicated operation and redundant equipment, and achieve the effects of simple operation, good plugging effect, and small weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

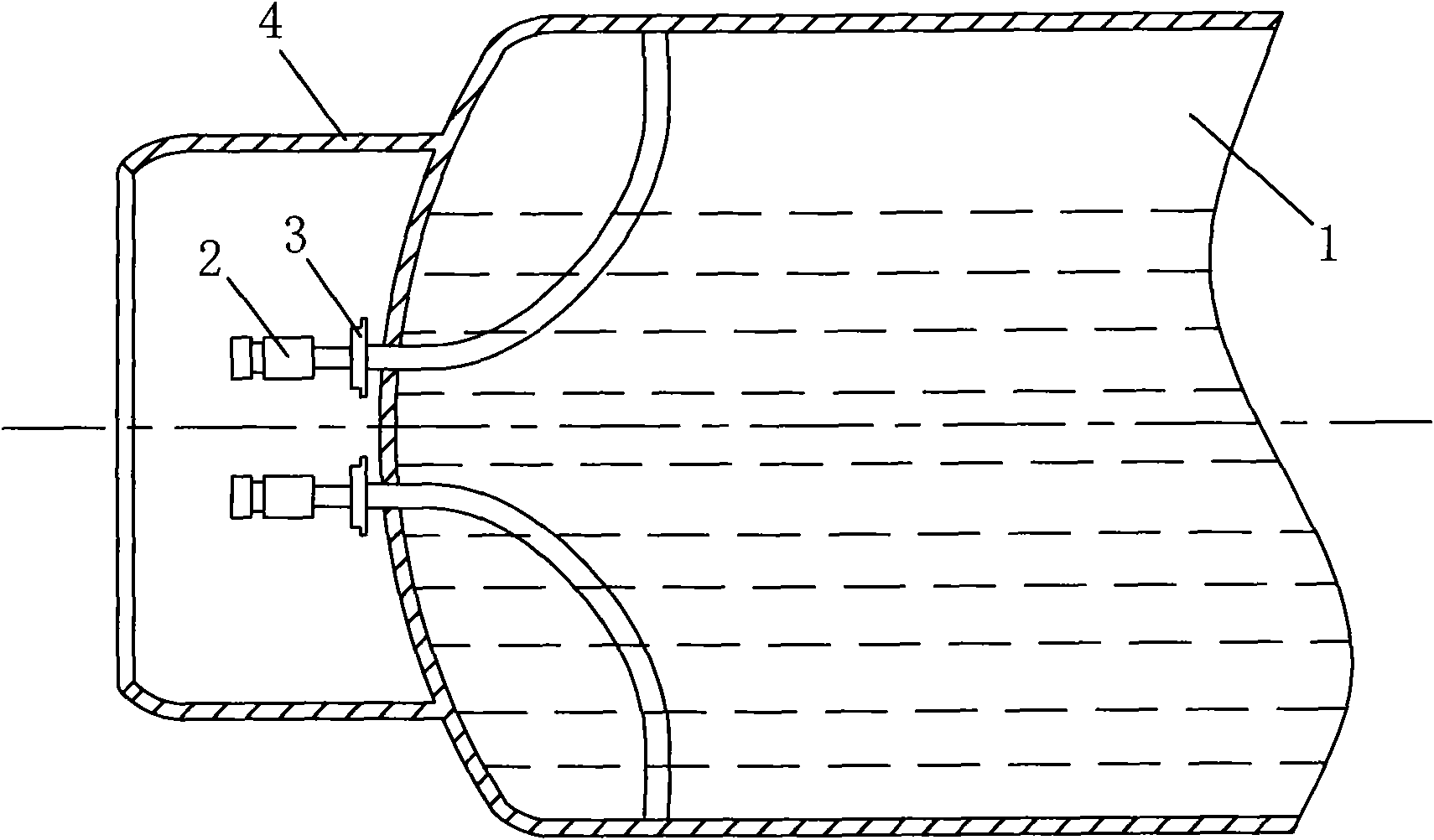

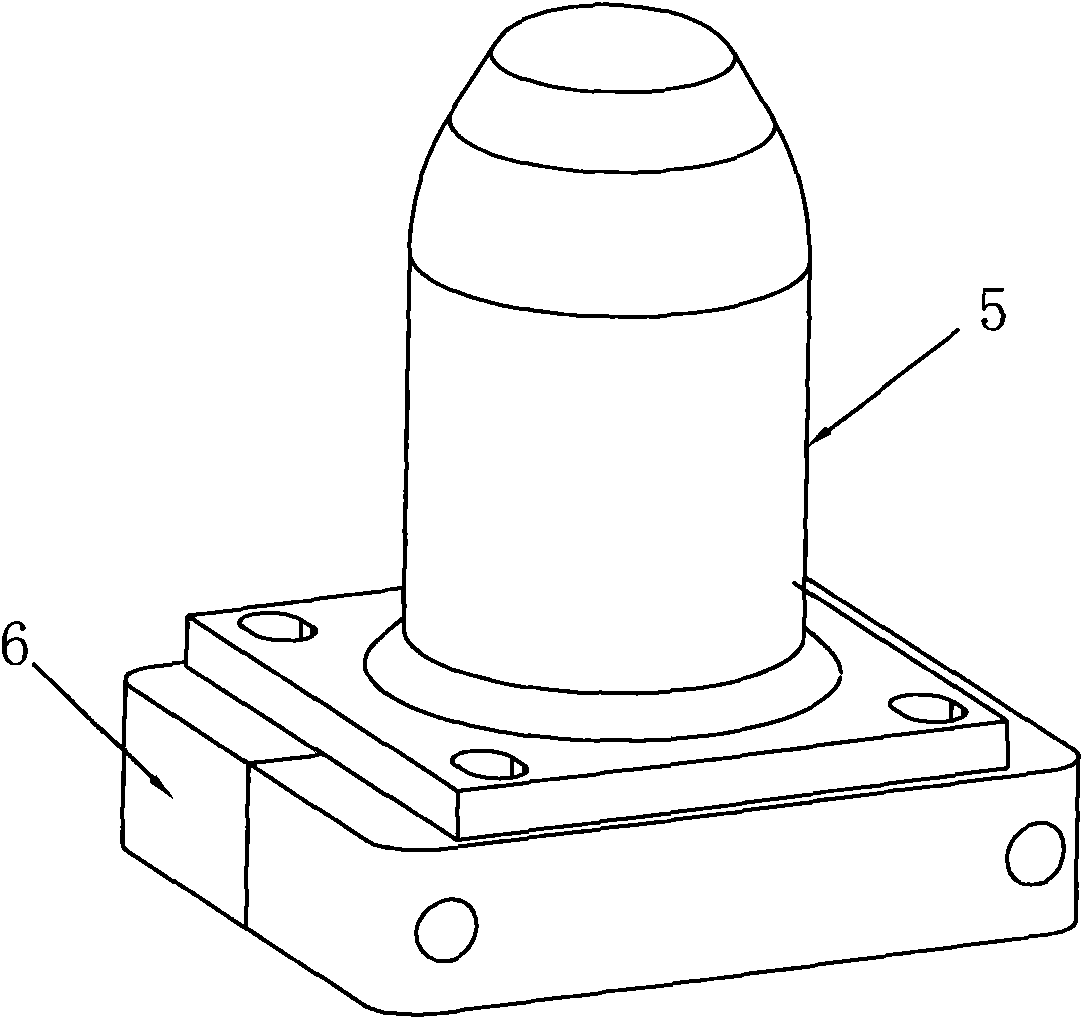

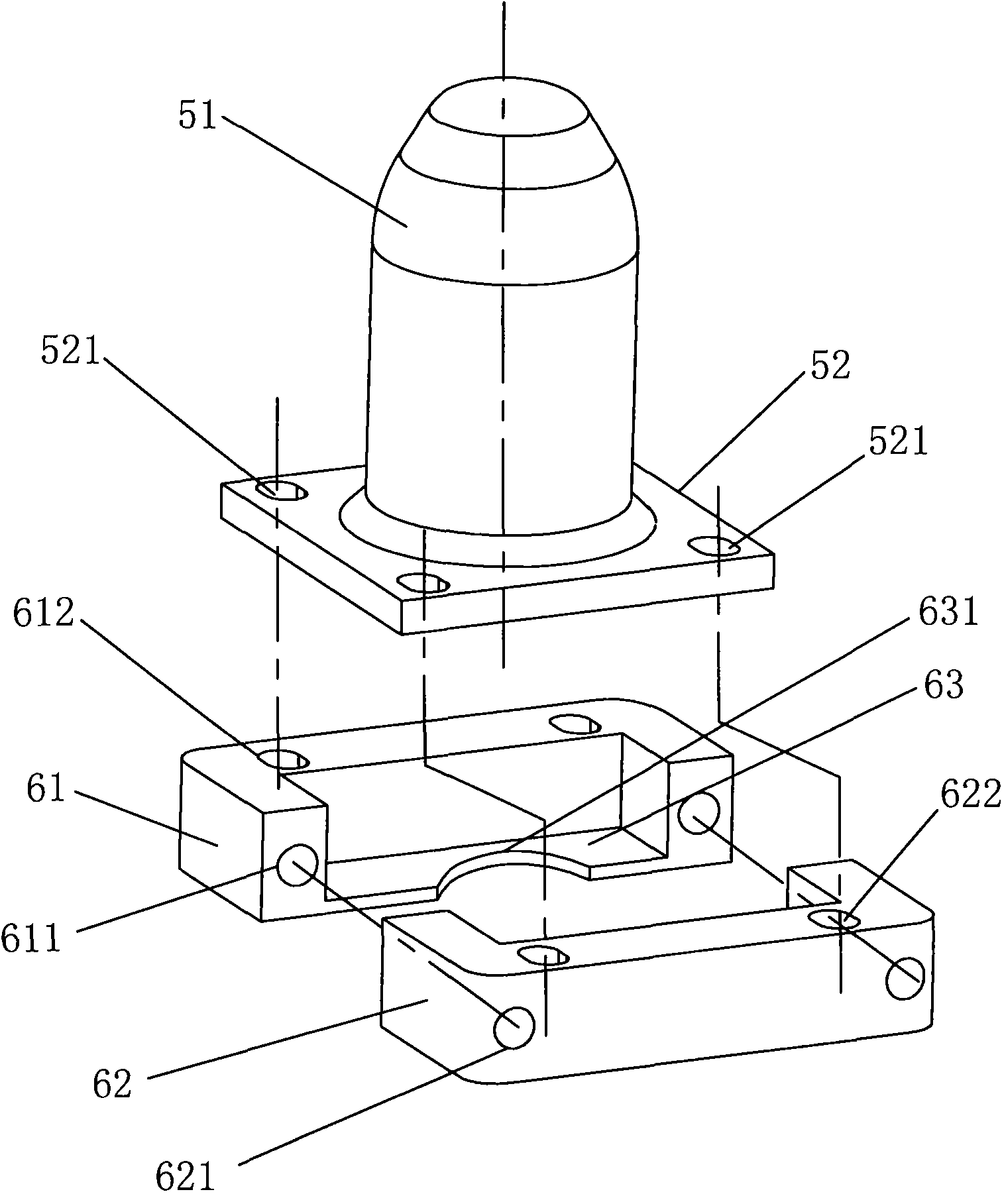

[0028] like figure 2 , image 3 As shown, it is a three-dimensional assembly view and an exploded view of a pressure vessel valve leak plugging device of the present invention, which includes two parts: a cover body 5 and a seat body 6, wherein:

[0029] The cover 5 includes an integrally connected airtight cover 51 and an upper cover 52, the airtight cover 51 is provided with an opening, and the upper cover 52 is connected to the opening of the airtight cover 51, The upper cover plate 52 is provided with several connecting holes 521, which are used for fastening connection with the seat body 6; in addition, in order to ensure the airtight effect of the leakage plugging device, a sealing ring 53 ( See Figure 4 );

[0030] The seat body 6 includes a left base 61 and a right base 62 which are arranged oppositely, and a lower bottom plate 63 is extended on the left base 61 and the right base 62 respectively, and the lower bottom plate 63 is used to abut against the valve On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com