Single-needle electronic pulse ignition induction circuit

An electronic pulse and induction circuit technology, applied in the direction of ignition by electric spark, circuit dedicated to spark gap, circuit, etc., can solve the problems of limited service life of gas discharge tube, drop of initial discharge voltage, unreliable trigger mode, etc. , to achieve low manufacturing cost, low on-resistance, and prevent false triggering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

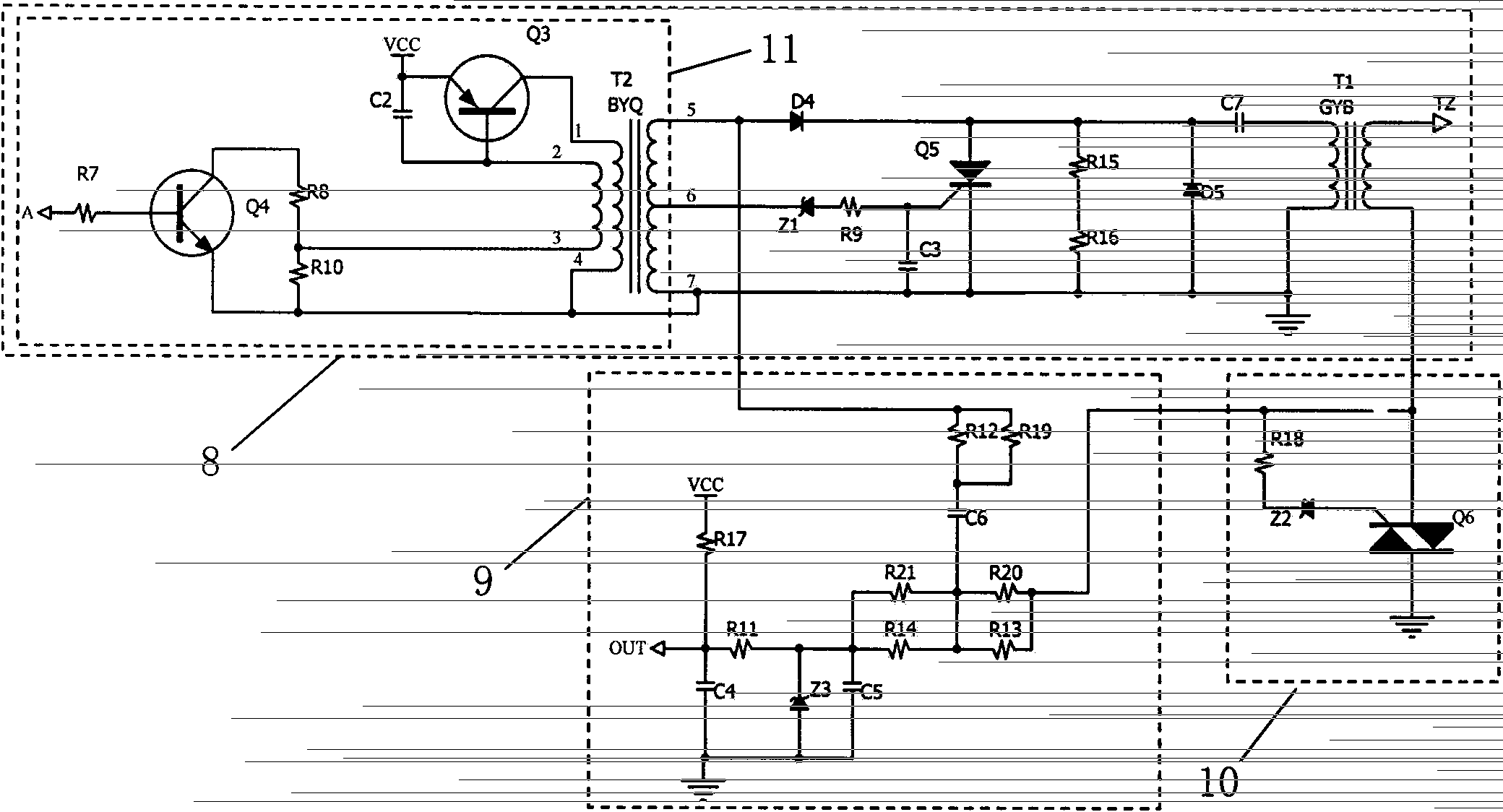

[0021] Such as figure 1 A single-needle electronic pulse ignition induction circuit shown includes an energy storage trigger ignition circuit 8 and a flame ion detection circuit 9, and the energy storage trigger ignition circuit 1 also includes a boost oscillating circuit 11, and the boost oscillating circuit 11 Including triode Q3 and triode Q4, the emitter of triode Q3 is connected to the AC voltage Vcc input, the collector is connected to port 1 of the first primary of a transformer T2, and the base is respectively connected to the anodes of the shunt resistors R8 and R10 through the second primary end of the transformer T2. The cathode of the shunt resistor R8 is connected to the collector of the transistor Q4, the emitter of the transistor Q4 is connected to the cathode of the shunt resistor R10 to ground, and a control input terminal A is connected to the base of the transistor Q4; the first primary 4 terminals of the transformer T4 are grounded. The energy storage trigg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com